Preparation method and application of molybdenum carbide/ zinc indium sulfide composite photocatalyst

A technology of catalyst and composite light, which is applied in the field of photocatalytic materials, can solve the problem of low photocatalytic activity of photocatalysts, and achieve the effects of simple and effective composite methods, high use value and application prospects, and efficient reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

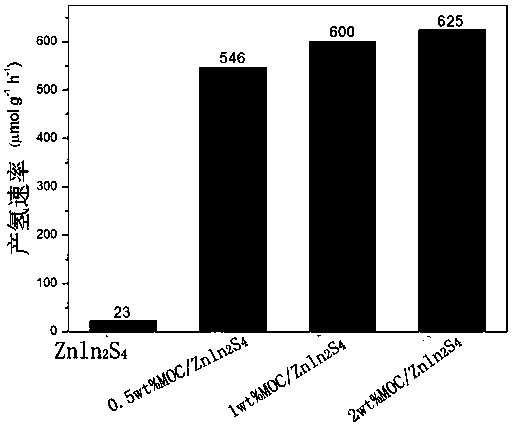

[0022] MoC / ZnIn with efficient and stable photocatalytic hydrogen production performance 2 S 4 Preparation of Composite Photocatalyst

[0023] Add 2.645 mg MoC to 50 mL containing 0.3595 g ZnSO 4 ·7H 2 O, 0.9548 g In(NO 3 ) 3 4.5H 2 O. In an aqueous solution of 0.7513 g TAA, a uniform suspension was obtained, and the obtained suspension was transferred into a 100 mL reaction kettle with a polytetrafluoroethylene substrate, placed in an oven at 200 ° C for 12 h, and then cooled naturally to room temperature, then washed several times with absolute ethanol and deionized water and dried to obtain MoC / ZnIn with MoC content of 0.5 wt%. 2 S 4 composite photocatalyst.

Embodiment 2

[0025] Add 5.29 mg MoC to 50 mL containing 0.3595 g ZnSO 4 ·7H 2 O, 0.9548 g In(NO 3 ) 3 4.5H 2 O. In an aqueous solution of 0.7513 g TAA, a uniform suspension was obtained, and the obtained suspension was transferred to a 100 mL reaction kettle with a polytetrafluoroethylene substrate, placed in an oven at 200 ° C for 12 h, and then cooled naturally to room temperature, then washed with absolute ethanol and deionized water to obtain a precipitate, and then dried the precipitate to obtain MoC / ZnIn with a MoC content of 1 wt%. 2 S 4 composite photocatalyst.

Embodiment 3

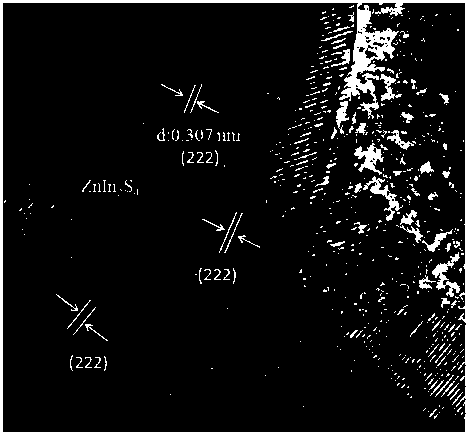

[0027] Add 10.58 mg MoC to 50 mL containing 0.3595 g ZnSO 4 ·7H 2 O, 0.9548 g In(NO 3 ) 3 4.5H 2 O. In an aqueous solution of 0.7513 g TAA, a uniform suspension was obtained, and the obtained suspension was transferred to a 100 mL reaction kettle with a polytetrafluoroethylene substrate, placed in an oven at 200 ° C for 12 h, and then cooled naturally to room temperature, then washed with absolute ethanol and deionized water to obtain a precipitate, and then dried the precipitate to obtain MoC / ZnIn with a MoC content of 2 wt%. 2 S 4 composite photocatalyst. The measured transmission electron microscope spectrum is as figure 1 As shown, the (111) plane of MoC and ZnIn can be clearly observed in the figure 2 S 4 The lattice fringes of the (222) plane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com