Underwater robot control system and method for submarine cable routing inspection

An underwater robot and submarine cable technology, which is applied in the installation of cables, underwater ships, cable installation devices, etc., can solve problems such as restricting applications, hindering intelligent systems, increasing the load burden of underwater robots, etc., to improve practicability , the effect of reducing size and weight, and improving autonomous working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

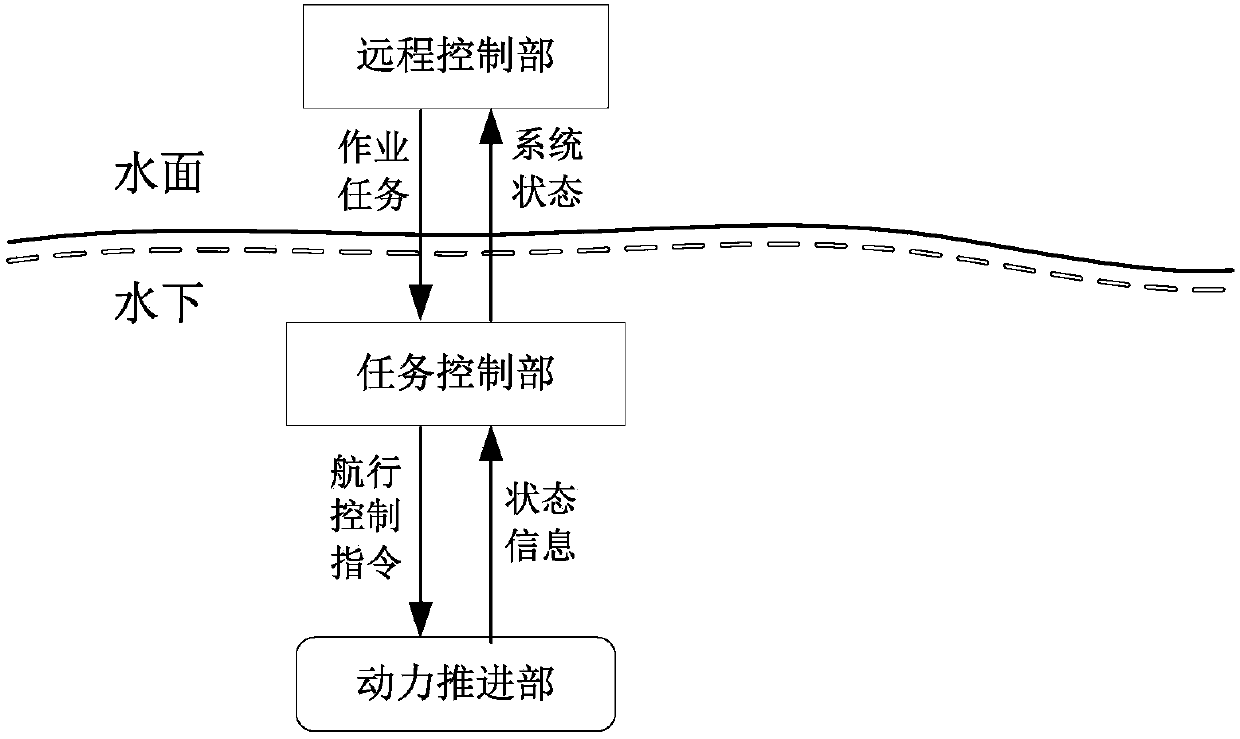

[0057] figure 1 It is a structural schematic diagram of Embodiment 1 of the underwater robot control system for submarine cable inspection of the present invention.

[0058] Such as figure 1 As shown, a kind of underwater robot control system for submarine cable inspection of the present invention comprises:

[0059] The remote control department, which is located above the water surface and is responsible for issuing operational tasks to the underwater robot; and

[0060] The task control unit is connected to the power propulsion unit; the task control unit is configured to: receive the operation tasks issued by the remote control unit, and plan the path of the operation tasks to control the power propulsion unit to implement corresponding actions, so as to realize multiple Freedom navigation; at the same time, the navigation parameters are adjusted in real time to ensure that the underwater robot can successfully complete the given task.

[0061] (1) Mission Control Depar...

Embodiment 2

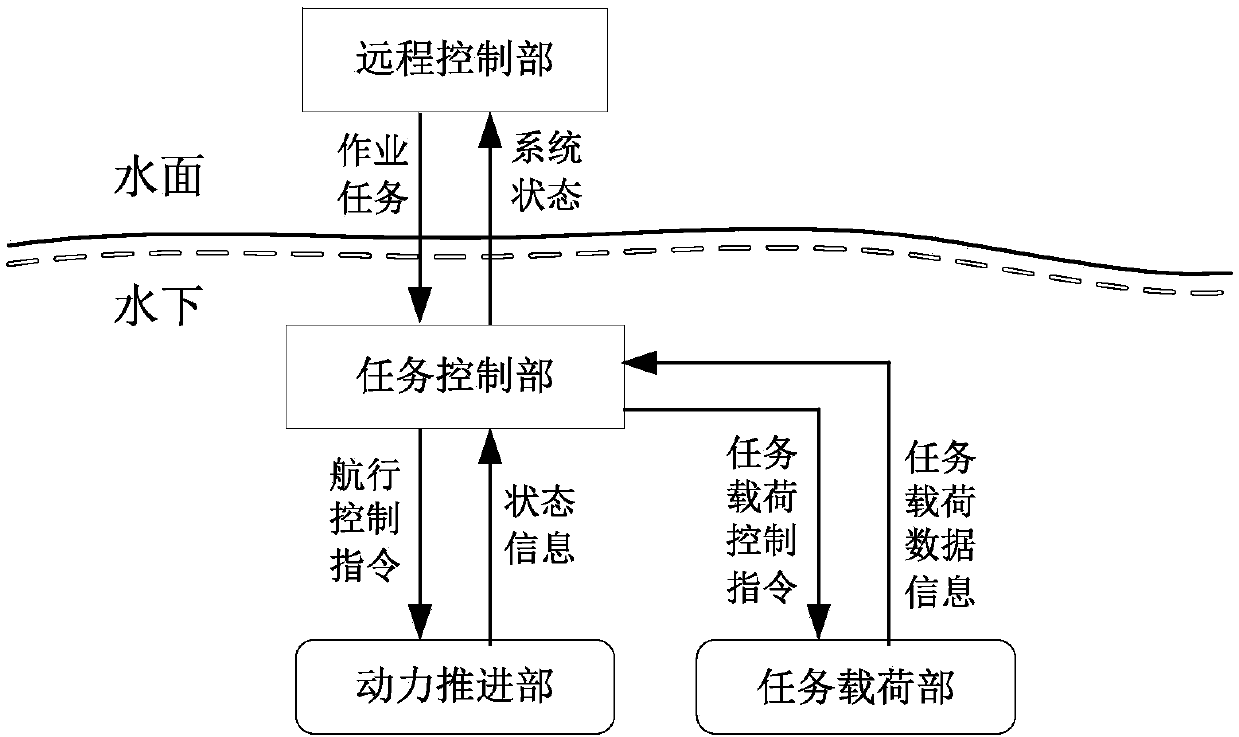

[0110] figure 2 It is a structural schematic diagram of Embodiment 2 of the underwater robot control system for submarine cable inspection of the present invention.

[0111] like figure 2 As shown, on the basis of the first embodiment, the underwater robot control system for submarine cable inspection in this embodiment also includes a task load unit.

[0112] The task load part is connected with the task controller, and the task load part is configured to: adopt the task load reconstruction design, and carry different task loads at the same body position according to the operation tasks.

[0113] The present invention not only reduces the size and weight of the underwater robot by adopting the reconfiguration design, but also meets the requirements of different working environments and tasks, and improves the practicability of the underwater robot inspection operation.

[0114] Specifically, the mission load is an underwater camera, side-scan sonar, multi-beam sonar, shal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com