A method of transport control

A conveying control and controller technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of unfavorable workpiece distance detection, workpiece accumulation, undetectable workpieces, etc., and achieve continuous conveying and transfer , Guarantee the effect of transmission efficiency, continuity and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

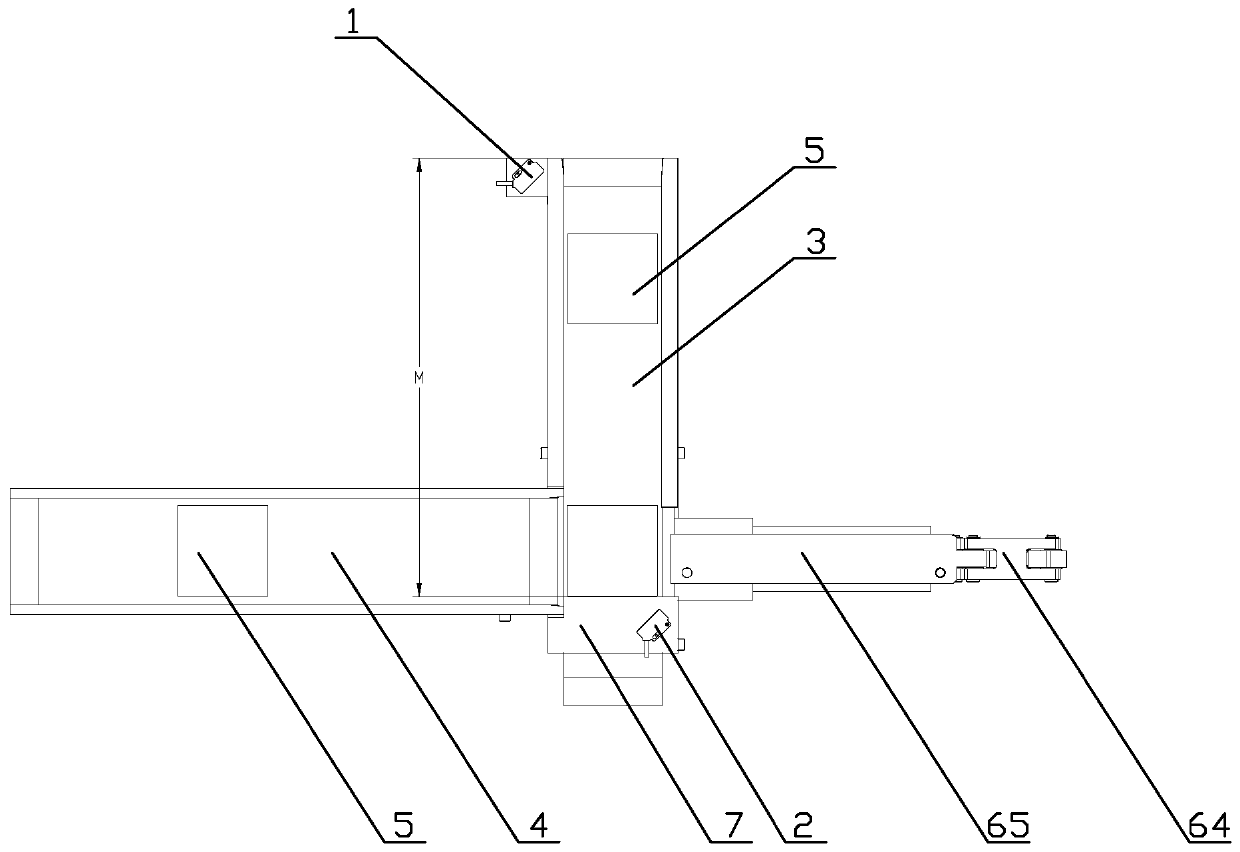

[0027] Such as figure 1 , a transfer control method, comprising the following steps,

[0028] A. The workpiece 5 is placed or transported to the first conveying device 3 and detected by the infrared sensor 1;

[0029] B. The conveying linear velocity V1 of the first conveying device 3 is set, and according to the conveying distance M on the first conveying device 3, the time S1 required for conveying a single workpiece 5 on the first conveying device 3 is obtained by calculating M / V1; figure 1 , the conveying distance is the linear distance between the top of the first conveying device and the abutment block;

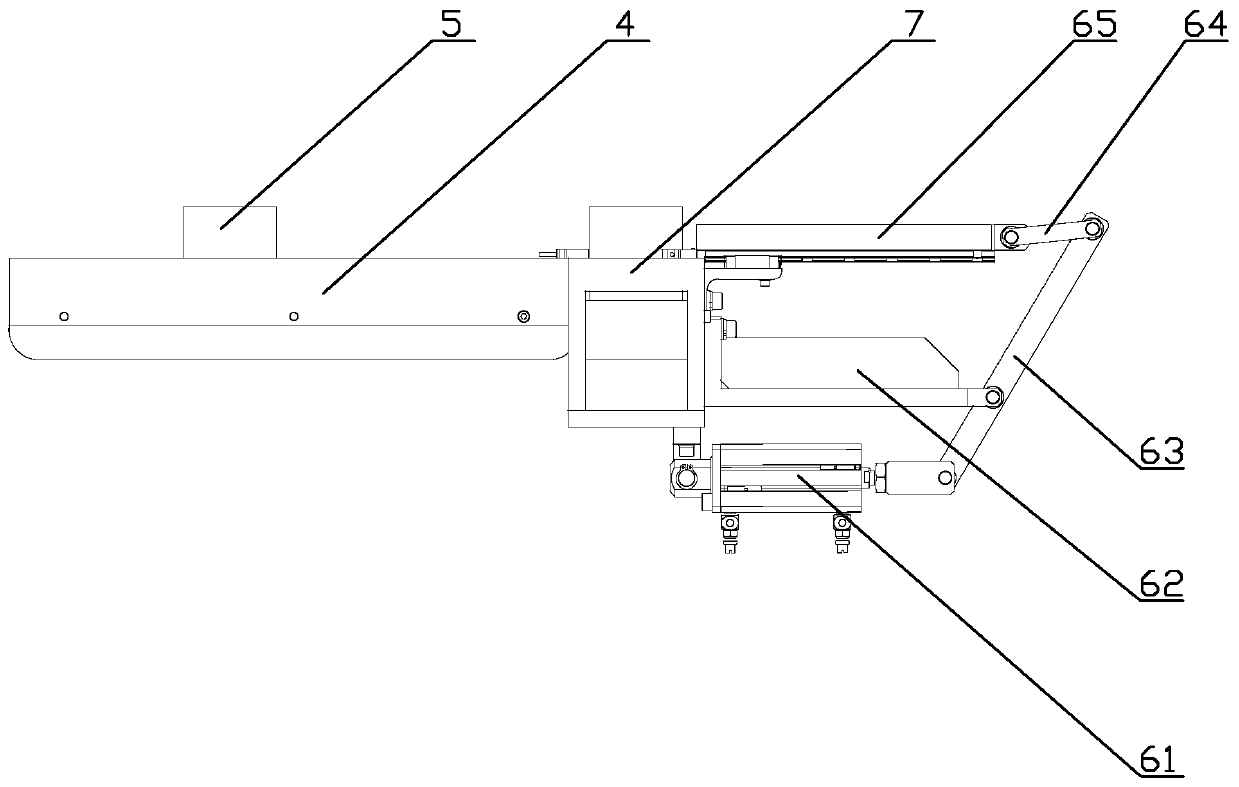

[0030] C, pushing assembly obtains the time interval of pushing the workpiece 5 according to the calculated time S1, which is the same as the value of S1; the pushing assembly of the present invention includes a cylinder 61, a fixed rod 62, a rotating rod 63, a driven rod 64 and push rod 65;

[0031] D. The controller controls the piston rod of the cylinder 61 to pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com