Method for preparing oxide ceramic target material green body

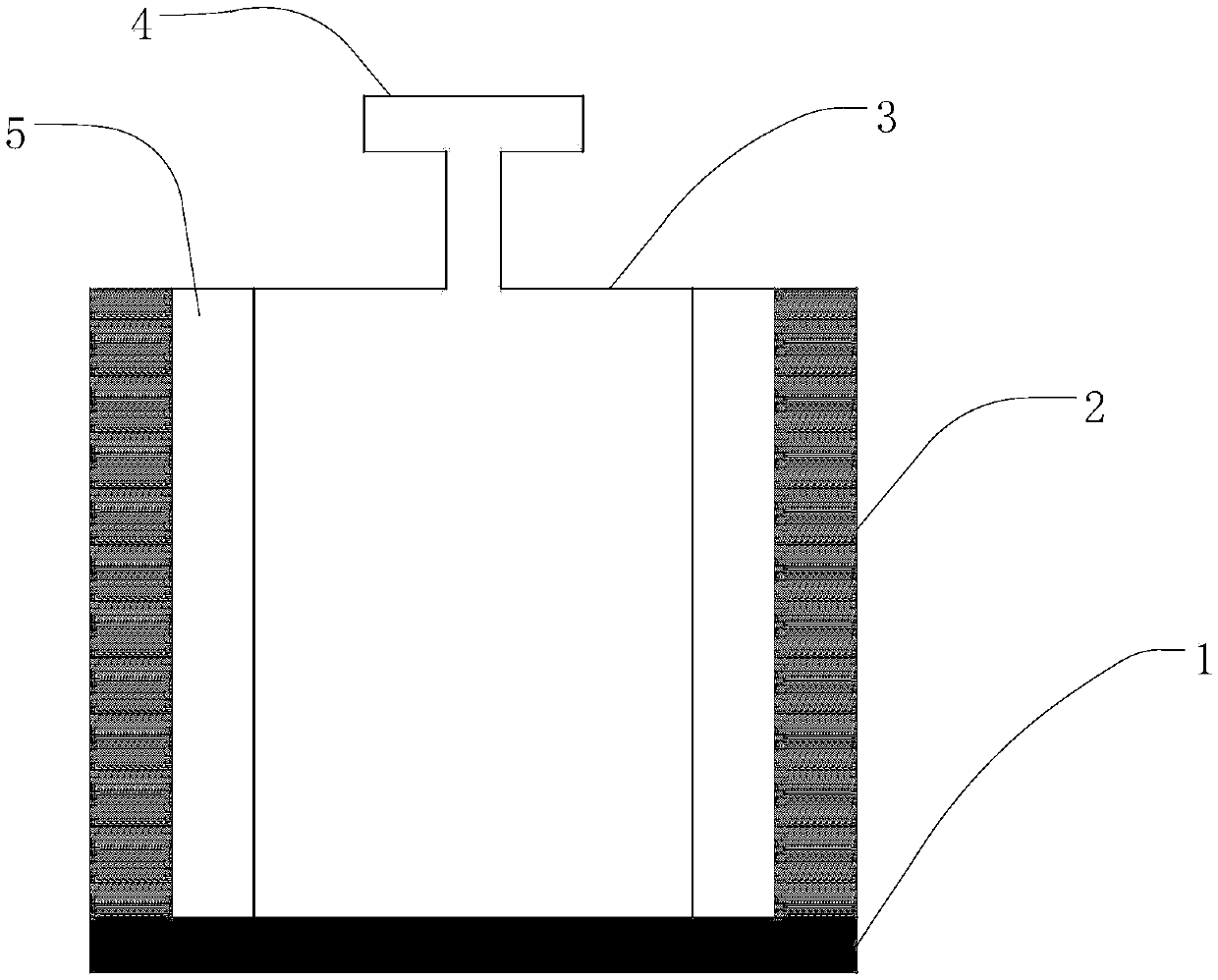

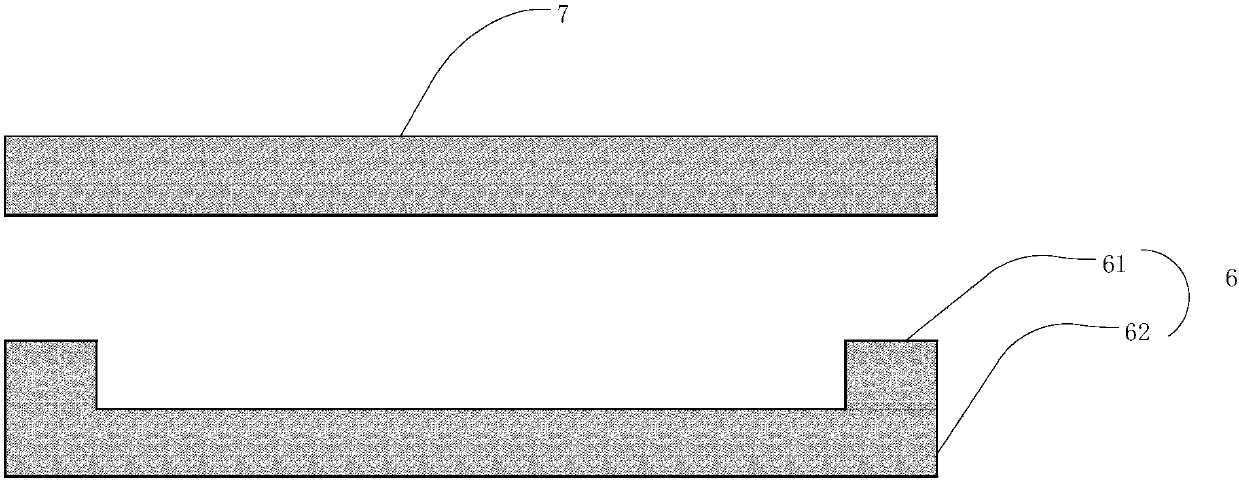

A technology for oxide ceramics and target blanks, which is applied to die-casting molds, molds, etc., can solve the problems of difficult production, complex structure, and difficult operation, and achieve the effects of good blank formability, simple process operation, and simple mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 A high-density ITO target was prepared using the method disclosed in the present invention.

[0053] The first step: prepare high volume solid content ITO slurry. Weigh the oxide powder In 2 o 3 450g and SnO 2 50g, add 7.5g of polyacrylic acid as dispersant, 2.5g of gum arabic as adhesive, 6g of high-molecular organic acrylamide and 75g of high-purity water to form a premix.

[0054] The second step: vacuum ball milling. After adding all the raw materials into the ball milling tank, vacuumize the ball milling tank until the vacuum degree reaches 10Pa, and then conduct long-term ball milling for 48 hours, and finally prepare an ITO slurry with a volume solid content of up to 48% and a viscosity as low as 100 centimeters Poor slurry.

[0055] In the third step, the obtained slurry is poured into a cylindrical plaster mold to form a green ITO oxide ceramic target.

[0056] In the fourth step, the green body obtained in the third step above is moved into a...

Embodiment 2

[0059] Example 2 A high-density IGZO target was prepared using the method disclosed in the present invention.

[0060] The first step: prepare high volume solid content IGZO slurry. Weigh 221.1g In respectively 2 o 3 Oxide powder, 149.25gGa 2 o 3 Oxide powder and 129.65g of ZnO oxide powder; 8.5g of dispersant polyacrylic acid, 1.5g of adhesive gum arabic, 5g of polymer organic acrylamide and 80g of high-purity water constitute the premix.

[0061] The second step: vacuum ball milling. After adding all the raw materials into the ball milling tank, vacuumize the ball milling tank until the vacuum degree reaches 9Pa, and then conduct long-term ball milling for 72 hours, and finally prepare an IGZO slurry with a volume solid content of up to 50% and a viscosity as low as 100 centimeters Poor slurry.

[0062] In the third step, the ball-milled slurry is poured into a cylindrical plaster mold to form a green IGZO oxide ceramic target.

[0063] In the fourth step, the green b...

Embodiment 3

[0066] Example 3 A high-density AZO target was prepared using the method disclosed in the present invention.

[0067] The first step: prepare AZO slurry with high volume solid content. Weigh the oxide powder ZnO mass as 490g and Al respectively 2 o 3 The mass of alumina is 10g; add 5.5g of polyacrylic acid as a dispersant, 3.5g of gum arabic as an adhesive, 4g of acrylamide as an organic polymer and 95g of high-purity water to form a premix.

[0068] The second step: vacuum ball milling. After adding all the raw materials into the ball milling tank, vacuumize the ball milling tank until the vacuum degree reaches 9.5Pa, and then conduct long-term ball milling for 60 hours, and finally prepare an AZO slurry with a volume solid content of up to 51% and a viscosity as low as 100 centipoise slurry.

[0069] In the third step, the ball-milled slurry is poured into a flat plaster mold for molding to obtain a green AZO oxide ceramic target.

[0070] In the fourth step, the green ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com