Center opening type in-order split propellant powder and forming mold thereof

A technology for forming molds and propellants, which is applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems that there are no detailed reports on the processing technology of pressing molds, and achieve adjustable and controllable energy release laws, optimized combustion performance, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment adopts the mold of the above-mentioned technical solution, and the specific parameters are listed as follows.

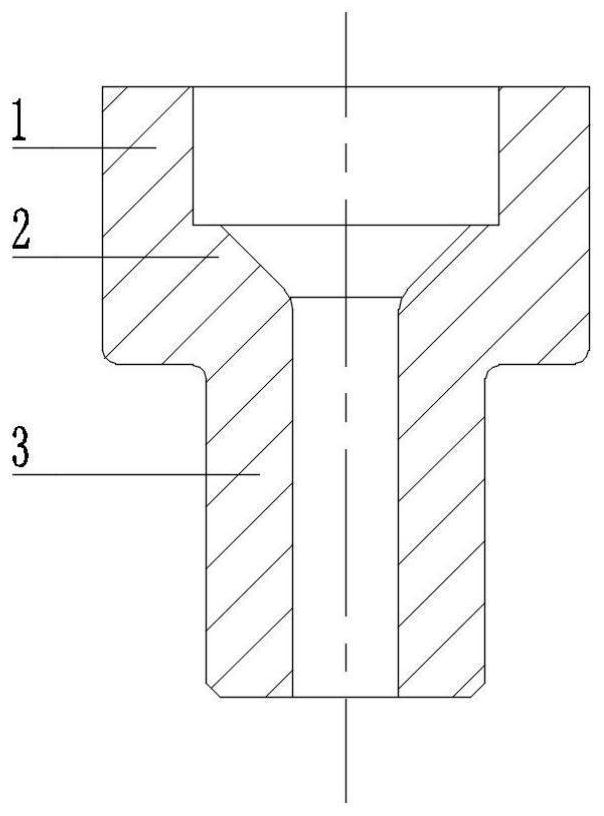

[0039] Mold body part: the inner diameter of needle frame positioning hole 1 is 24mm, the length of shrinkage hole 2 is 5mm, the shrinkage angle is 40°, the length of forming hole 3 is 32mm, and the diameter of forming hole 3 is 7mm.

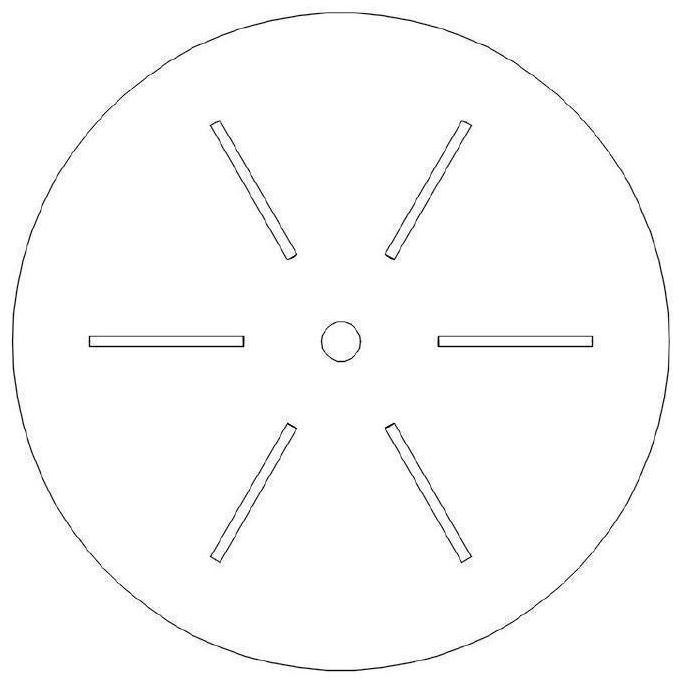

[0040] Needle frame part: the thickness of the needle frame is 5mm.

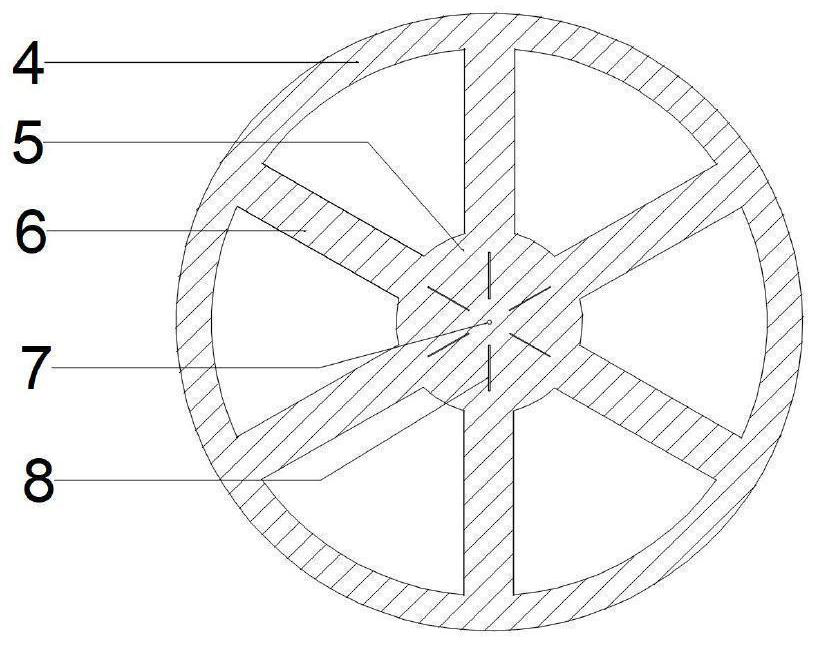

[0041] Mold needle part: The mold needle used is composed of a round needle with a diameter of 0.4mm and 6 piece needles evenly distributed along the circumference. The length of the forming rod 10 is 42mm, the width is 50% of the total arc thickness of the propellant, and the thickness is 0.2mm; the width of the positioning piece 9 exceeds the width of the forming rod by 1mm, the length is 6mm, and the thickness is 0.2mm.

[0042] Figure 5 It is the physical map of the propellant prepared under this condition. As shown in the figure, there...

Embodiment 2

[0044] This embodiment adopts the mold of the above-mentioned technical solution, and the specific parameters are listed as follows.

[0045] Mold part: the inner diameter of the positioning hole of the needle frame is 24mm, the length of the shrinkage hole is 5mm, the shrinkage angle is 50°, the length of the forming hole is 32mm, and the diameter of the forming hole is 6mm.

[0046] Needle frame part: the thickness of the needle frame is 5mm.

[0047] Mold needle part: The mold needle used is composed of a round needle with a diameter of 0.3mm and 8 piece needles evenly distributed along the circumference. The length of the forming rod is 42mm, the width is 70% of the total arc thickness of the propellant, and the thickness is 0.15mm; the width of the positioning piece exceeds the width of the forming rod by 1mm, the length is 5mm, and the thickness is 0.15mm.

Embodiment 3

[0049] This embodiment adopts the mold of the above-mentioned technical solution, and the specific parameters are listed as follows.

[0050] Mold part: Needle holder positioning hole 1 inner diameter is 24mm, shrinkage hole 2 length is 5mm, shrinkage angle is 55°, forming hole length is 32mm, forming hole diameter is 6.5mm, etc.

[0051] Mold needle part: The mold needle used is composed of a round needle with a diameter of 0.6mm and 12 piece needles evenly distributed along the circumference. The length of the forming rod 10 is 42mm, the width is 60% of the total arc thickness of the propellant, and the thickness is 0.3mm; the width of the positioning piece exceeds the width of the forming rod by 1mm, the length is 6mm, and the thickness is 0.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com