Isobaric preparation process for polytetrafluoroethylene lining of pipeline

A polytetrafluoroethylene and preparation process technology, applied in the field of pipeline lining, can solve the problems of uneven pressure, easy cracking between layers, large shrinkage rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

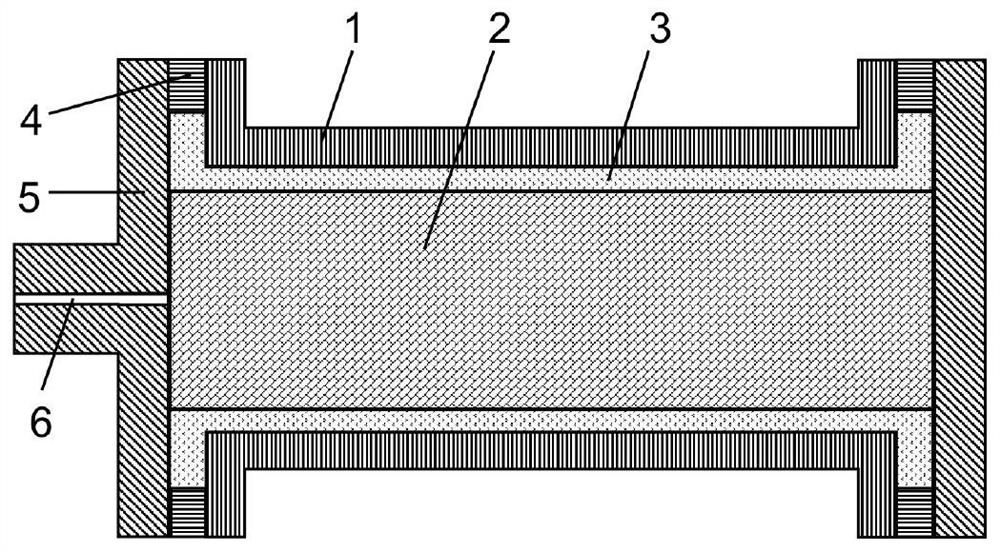

[0026] Embodiment 1: With reference to the accompanying drawings, the preparation process of the pipeline polytetrafluoroethylene lining, the specific operation process is as follows:

[0027] A. Treatment of the inner surface of the steel pipe: firstly, the inner surface of the pipeline 1 is degreased and rust-removed, and the rust-removing level inside the steel pipe is reached to Sa2 by sandblasting;

[0028] B. Put rubber bag soft mold: put rubber bag soft mold 2 into the pipe, the thickness of the rubber bag is 3 mm, and leave a uniform gap of 16 mm between the rubber bag and the pipe;

[0029] C. Add polytetrafluoroethylene powder: add polytetrafluoroethylene powder with a particle size of 700 μm into the gap between the rubber bag and the pipe, fill it evenly, and form a polytetrafluoroethylene layer 3;

[0030] D. Sealing: put in the binder ring 4 and the end cover 5, and tighten them with bolts to seal the pipeline tightly;

[0031] E. Place in the autoclave for wate...

Embodiment 2

[0036] Embodiment 2: With reference to the accompanying drawings, the preparation process of the pipeline polytetrafluoroethylene lining, the specific operation process is as follows:

[0037] A. Treatment of the inner surface of the steel pipe: firstly, the inner surface of the pipeline 1 is degreased and rust-removed, and the rust-removal level inside the steel pipe is reached to Sa2.5 by sandblasting;

[0038] B. Put rubber bag soft mold: put rubber bag soft mold 2 into the pipe, the thickness of the rubber bag is 2 mm, and leave a uniform gap of 14 mm between the rubber bag and the pipe;

[0039] C. Add polytetrafluoroethylene powder: add polytetrafluoroethylene powder with a particle size of 500 μm into the gap between the rubber bag and the pipe, fill it evenly, and form a polytetrafluoroethylene layer 3;

[0040] D. Sealing: put in the binder ring 4 and the end cover 5, and tighten them with bolts to seal the pipeline tightly;

[0041] E. Place in the autoclave for wat...

Embodiment 3

[0046] Embodiment 3: With reference to the accompanying drawings, the preparation process of the pipeline polytetrafluoroethylene lining, the specific operation process is as follows:

[0047] A. Treatment of the inner surface of the steel pipe: firstly, the inner surface of the pipeline 1 is degreased and rust-removed, and sandblasting is used to make the inner surface of the steel pipe reach Sa3 level;

[0048] B. Put rubber bag soft mold: put rubber bag soft mold 2 into the pipe, the thickness of the rubber bag is 2 mm, and leave a uniform gap of 12 mm between the rubber bag and the pipe;

[0049] C. Add polytetrafluoroethylene powder: add polytetrafluoroethylene powder with a particle size of 300 μm into the gap between the rubber bag and the pipe, fill it evenly, and form a polytetrafluoroethylene layer 3;

[0050] D. Sealing: put in the binder ring 4 and the end cover 5, and tighten them with bolts to seal the pipeline tightly;

[0051] E. Place in the autoclave for wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com