Inorganic modified high-molecular composite-sphere moisture-absorbing material and preparation method thereof

A hygroscopic material and inorganic modification technology, which is applied in the field of inorganic salt modified polymer composite ball hygroscopic material and its preparation, can solve the problems of low efficiency and slow moisture absorption rate, and achieve increased specific surface area, improved hygroscopic performance, and void space The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

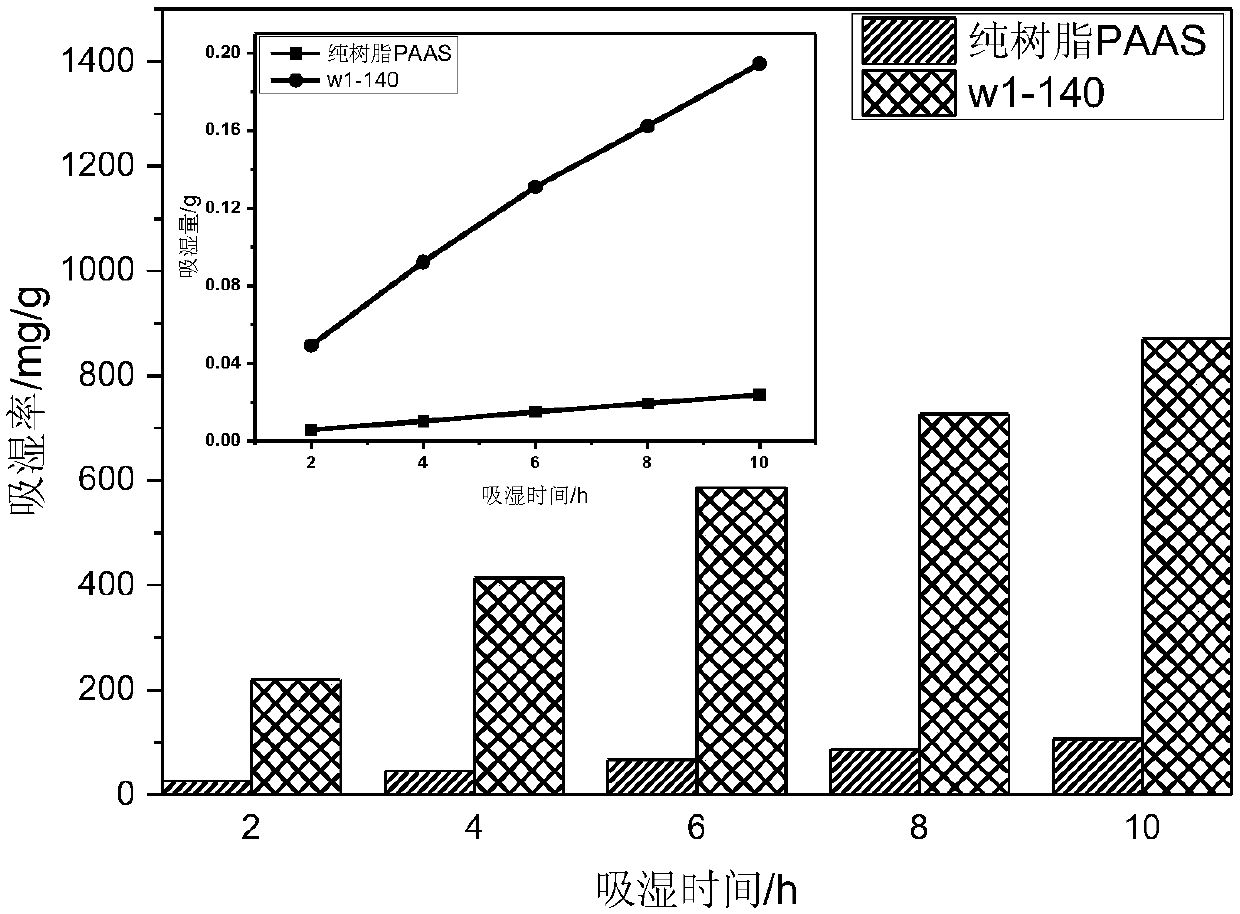

[0049] Take the superabsorbent resin ball and immerse it in deionized water to swell for 1 hour to 3 times its original volume, then take out the swollen ball, filter it out and dry it, and blend it with salt at a mass ratio of 1:50, so that the salt can be evenly coated on the On the surface of the ball, the blending time should be controlled within 5 minutes; take out the above-mentioned coated particles, let it stand at room temperature and air humidity less than 70% for 1 hour, then dry at 140°C for 3 hours, peel the dried composite ball Remove the surface salt shell to obtain w1-140 inorganic salt modified polymer composite particle balls; the average particle size of the composite balls is 0.697cm, and the average density is 0.503g / cm 3 , the mass ratio of resin and salt in the composite particle ball of this embodiment is 1:3.5.

[0050] figure 1 It is the moisture absorption curve measured by w1-140 composite particle ball and pure resin ball under the conditions of con...

Embodiment 2

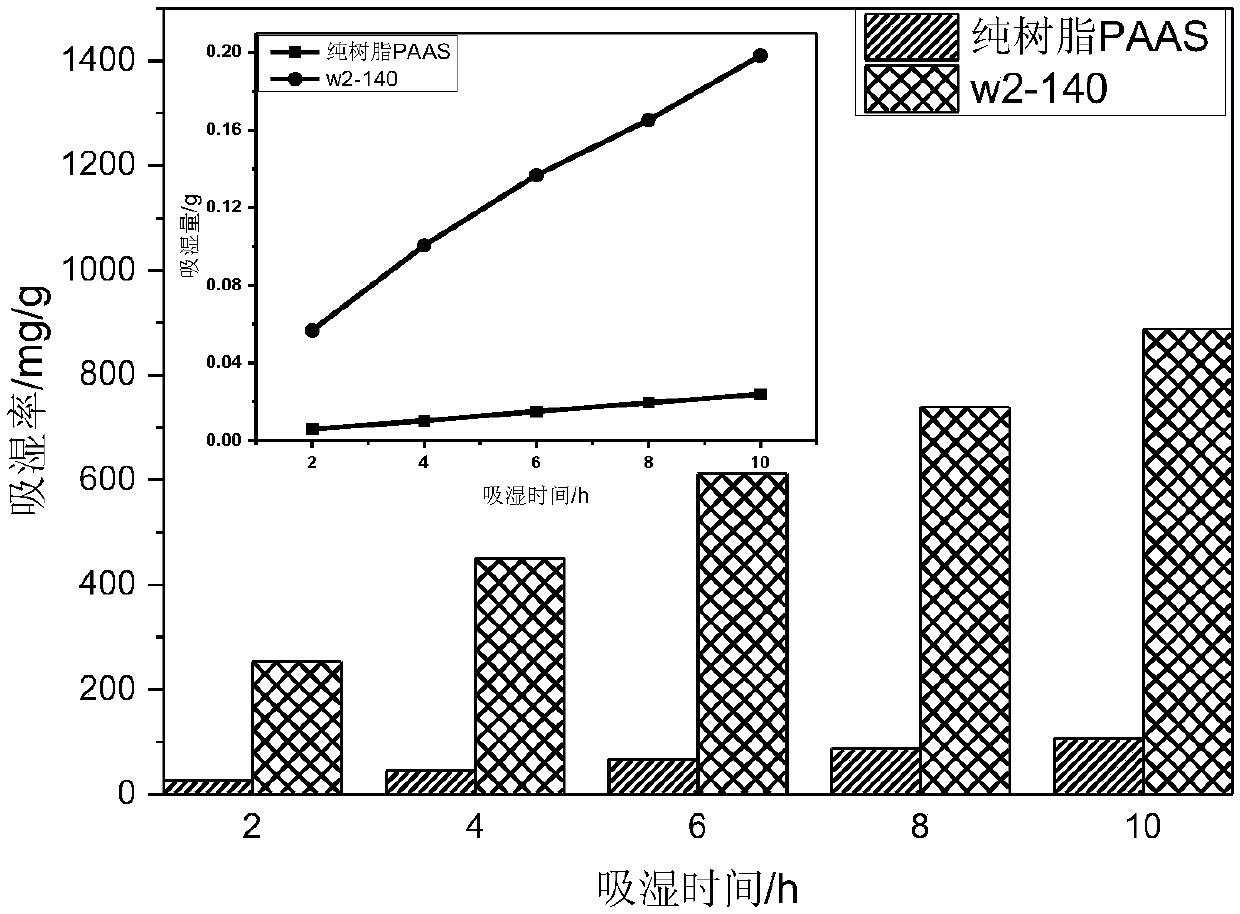

[0052] Take the superabsorbent resin ball and immerse it in deionized water to swell for 2 hours to 4 times the original volume, then take out the swollen ball, filter it out and dry it, and blend it with sodium chloride at a mass ratio of 1:40 to make the sodium chloride Evenly coat the surface of the pellets, and the blending time is controlled within 5 minutes; take out the above-mentioned coated particles, let them stand at room temperature and air humidity less than 70% for 1.5 hours, and then dry them at 140°C for 4 hours. The compound balls peel off the surface salt shell to obtain w2-140 inorganic salt modified polymer composite particle balls; the average particle size of the composite balls is 0.763cm, and the average density is 0.481g / cm 3 , the mass ratio of resin to sodium chloride in the composite particle ball of this embodiment is 1:4.9.

[0053] Under the conditions of constant temperature 30°C, humidity 100% and the same moisture absorption time, the moisture...

Embodiment 3

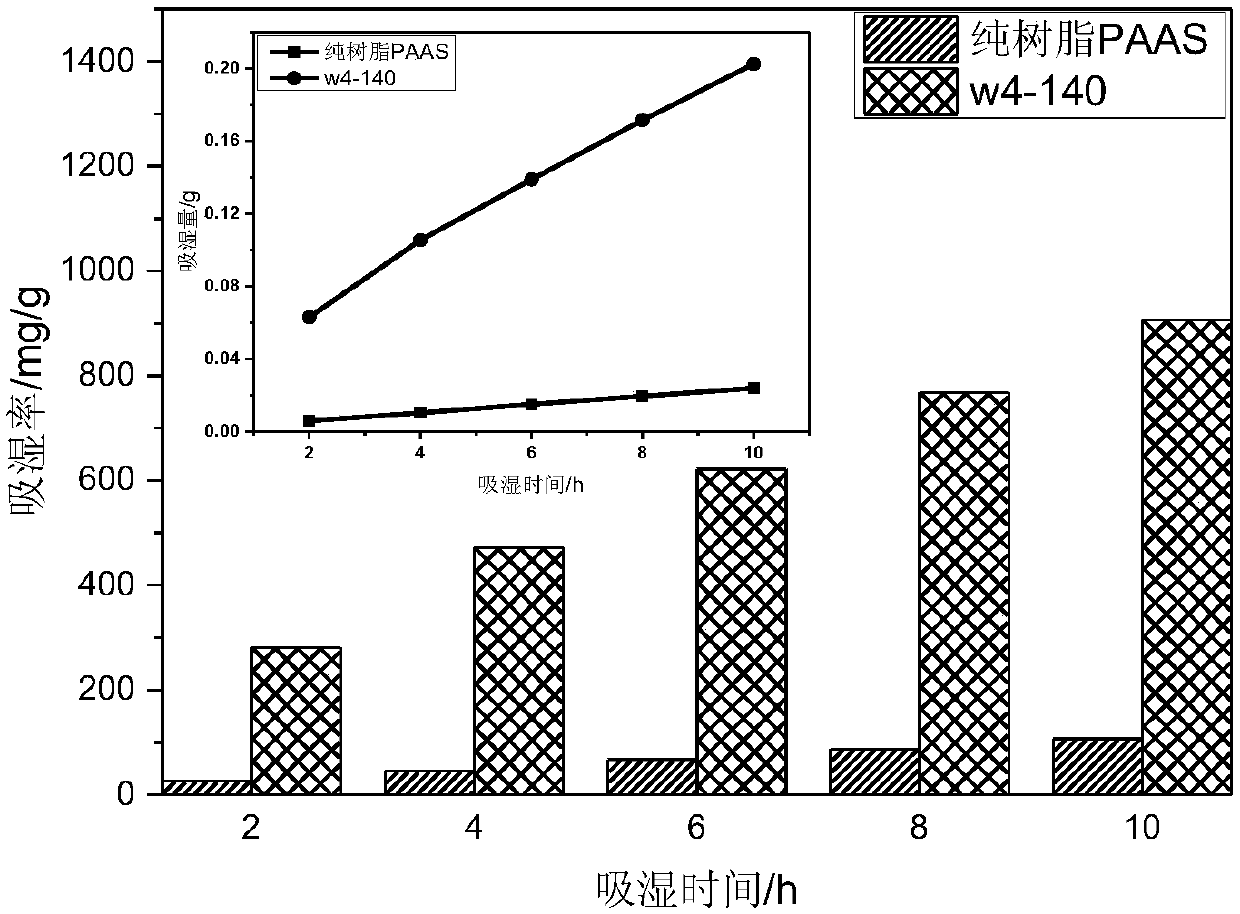

[0055] Take the superabsorbent resin ball and immerse it in deionized water to swell for 4 hours to 5 times its original volume, then take out the swollen ball, filter it out and dry it, and blend it with salt at a mass ratio of 1:30, so that the salt can be evenly coated on the On the surface of the bead, the blending time is controlled within 5 minutes; the above-mentioned coated particles are taken out, and left to stand for 2 hours at room temperature of 25°C and air humidity less than 70%, and then dried at 140°C for 3 hours, and the dried composite Peel off the salt shell on the surface of the ball to obtain w4-140 inorganic salt modified polymer composite particle ball; the average particle size of the composite ball is 0.810cm, and the average density is 0.467g / cm 3 , the mass ratio of resin and salt in the composite particle ball of this embodiment is 1:6.1.

[0056] Under the conditions of constant temperature 30°C, humidity 100% and the same moisture absorption time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com