Cooling system used for shaft system of wind generating set and wind generating set

A technology for wind turbines and cooling systems, applied in wind turbines, wind power generation, engines, etc., can solve problems affecting the life of lubricating grease, and achieve the effects of reliable installation, guaranteed service life, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

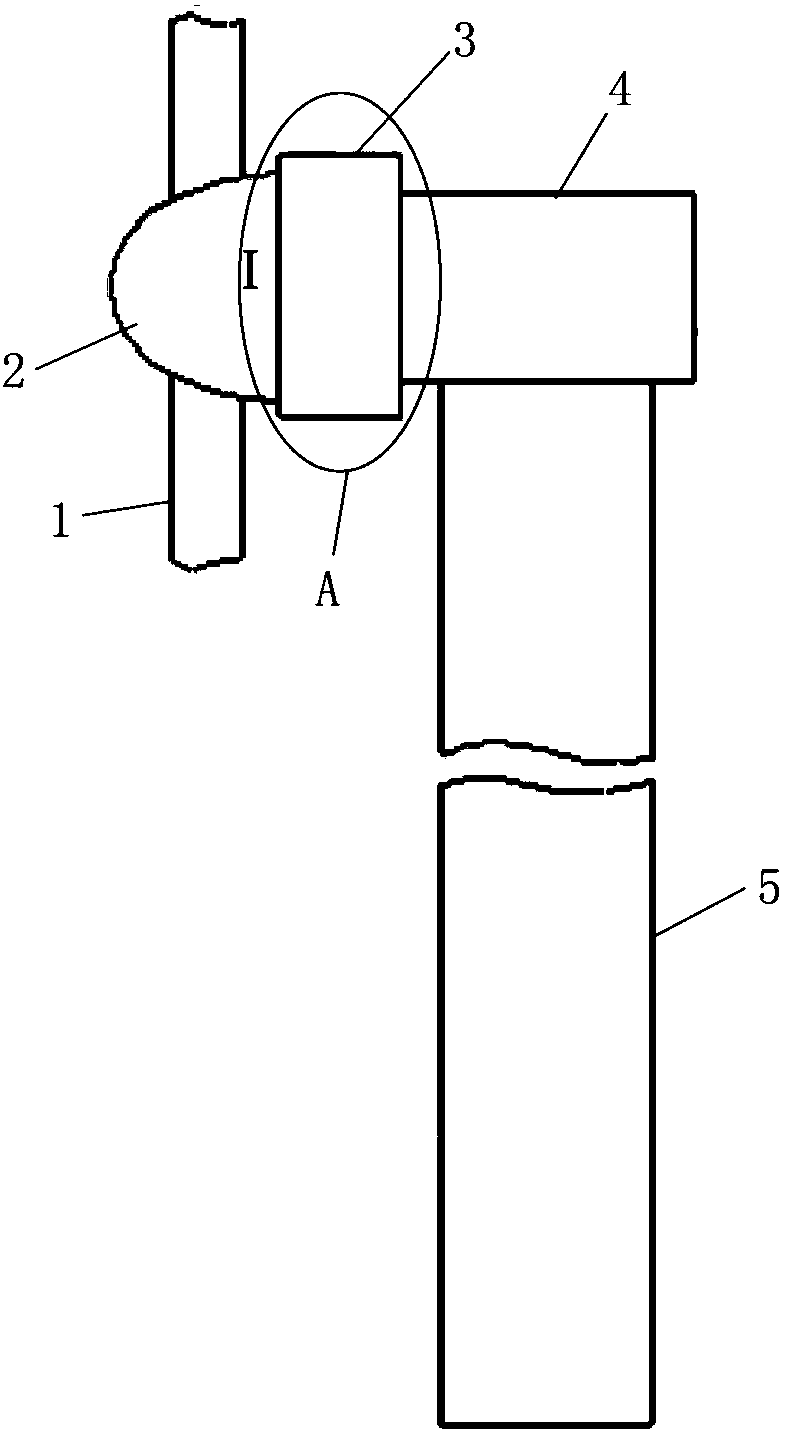

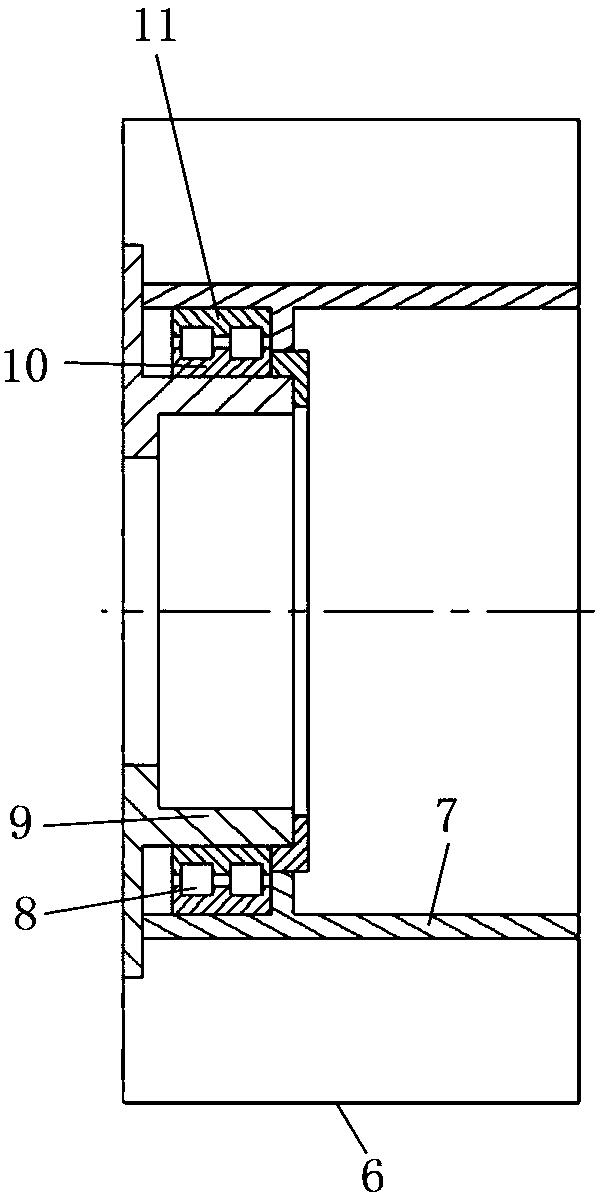

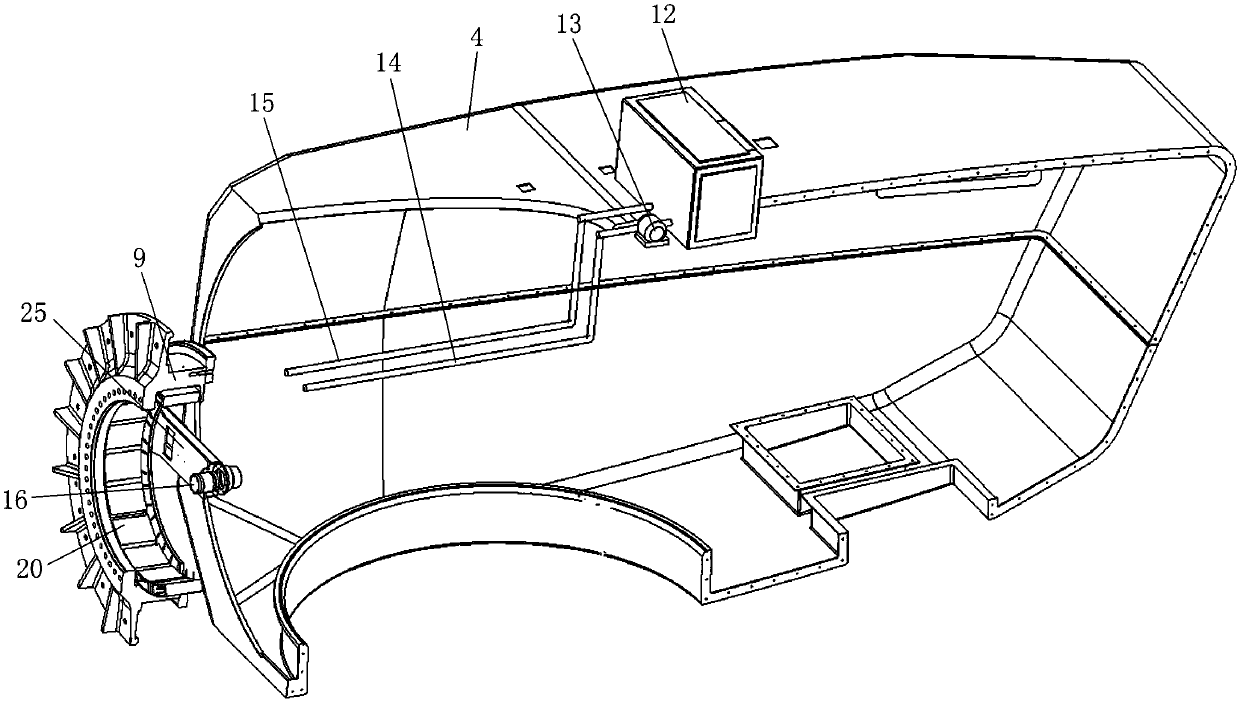

[0033] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings. In the following, the main bearing of the wind power generating set will be described as the cooling object, but it should be noted that the present invention is not limited thereto, and the cooling system according to the exemplary embodiment can also be applied to other shafting of the wind power generating set.

[0034] image 3It is a partially cut-away and exploded schematic diagram of a wind power generating set including a cooling system for a wind power generator according to an embodiment of the present invention; Figure 4 is a partial structural schematic diagram of a cooling system according to an embodiment of the present invention; Figure 5 is a structural schematic diagram of a heat dissipation substrate according to an embodiment of the present invention.

[0035] Such as image 3 and Figure 4 As shown, the cooling system accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com