Polymer cleaning method for etching cavity

A technology for etching chambers and polymers, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as plasma erosion, polymer accumulation, polymer accumulation, etc., to achieve improved yield, good cleaning, prevent cumulative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

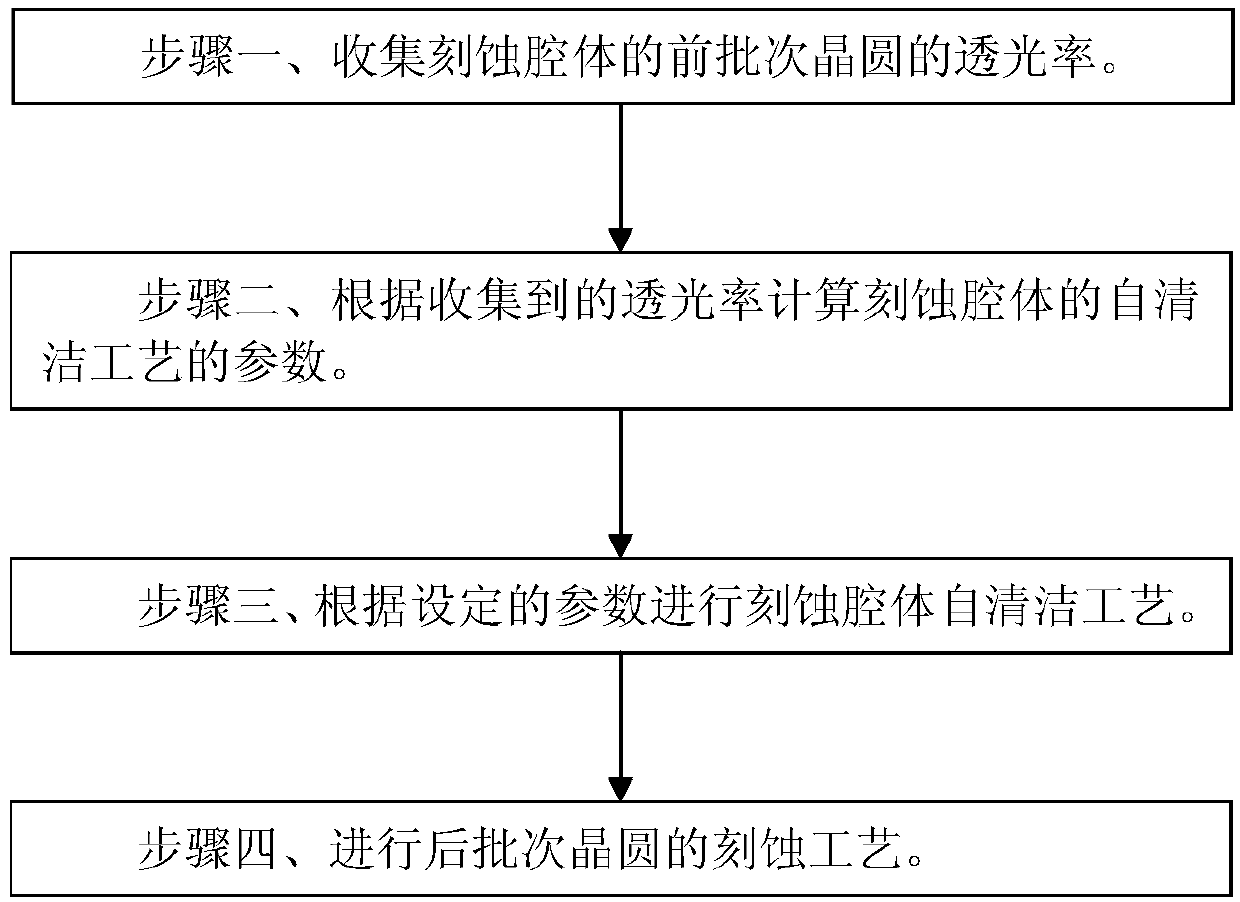

[0038] Such as figure 1 Shown is a flow chart of the polymer cleaning method for etching the cavity according to the embodiment of the present invention; the polymer cleaning method for etching the cavity according to the embodiment of the present invention includes the following steps:

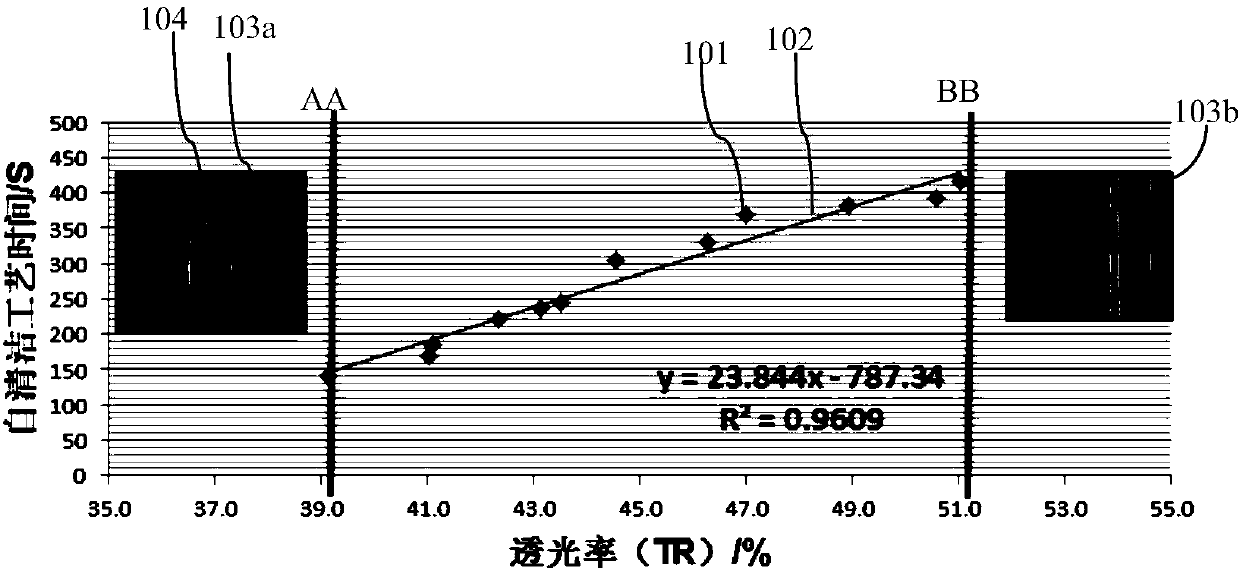

[0039] A step is performed before step 1: establishing a first relational expression and a corresponding first relational curve between the light transmittance of the wafer and the parameters of the self-cleaning process of the etching chamber.

[0040] The etching process of the first batch of wafers corresponding to the method of the embodiment of the present invention is the same as the etching process of the latter batch of wafers. That is, since the same etching process corresponds to the same etching program, the method of the embodiment of the present invention uses the same etching program to etch different batches of wafers.

[0041]The corresponding first relational expression and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com