Processing technology of deep narrow grooves on electrostatic chuck

An electrostatic chuck and processing technology, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of roughness that cannot pass the breakdown resistance test, high space utilization requirements, and broken milling cutters. Achieve the effect of facilitating sulfuric acid hard oxidation treatment and breakdown resistance test, improving machining accuracy and surface finish, and reducing the number of times of advancing and retreating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is further described;

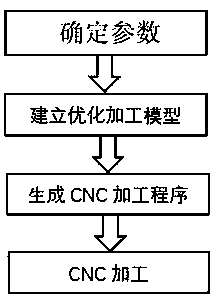

[0021] In the accompanying drawings: a processing technology for deep and narrow grooves on an electrostatic chuck, which is characterized in that it includes the following steps:

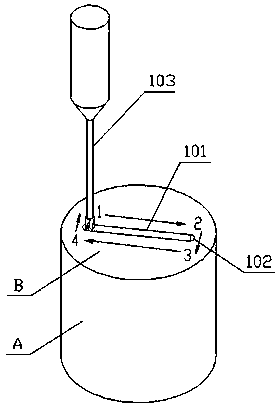

[0022] Step 1. Determine the parameters of the deep and narrow groove; according to the design requirements, considering the oxide film thickness after hard oxidation, determine the length, width and depth of the deep and narrow groove to be 5mm, 0.9mm, and 10mm respectively; the deep and narrow groove The cross-section is a waist-shaped structure, which is composed of a long slot 101 in the middle and arc-shaped slots 102 arranged at both ends of the long slot 101;

[0023] Step 2, computer software modeling; adopt the 3D design software in the prior art, such as UG etc.

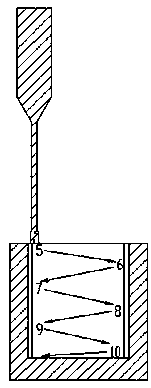

[0024] Step 3, programming operation; using XYZ three-axis linkage helical milling; compared with XY plane tool path, the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com