Knee joint osteotomy tool and its manufacturing system and manufacturing method

A knee joint and tool technology, applied in the field of knee joint osteotomy tools and its production system, can solve the problem of low accuracy of 3D knee joint digital models and anatomical feature identification points, long modeling time of 3D knee joint digital models, and osteotomy problems. Tool production time is long and other problems, to achieve the effect of solving low accuracy, increasing matching degree, and avoiding noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

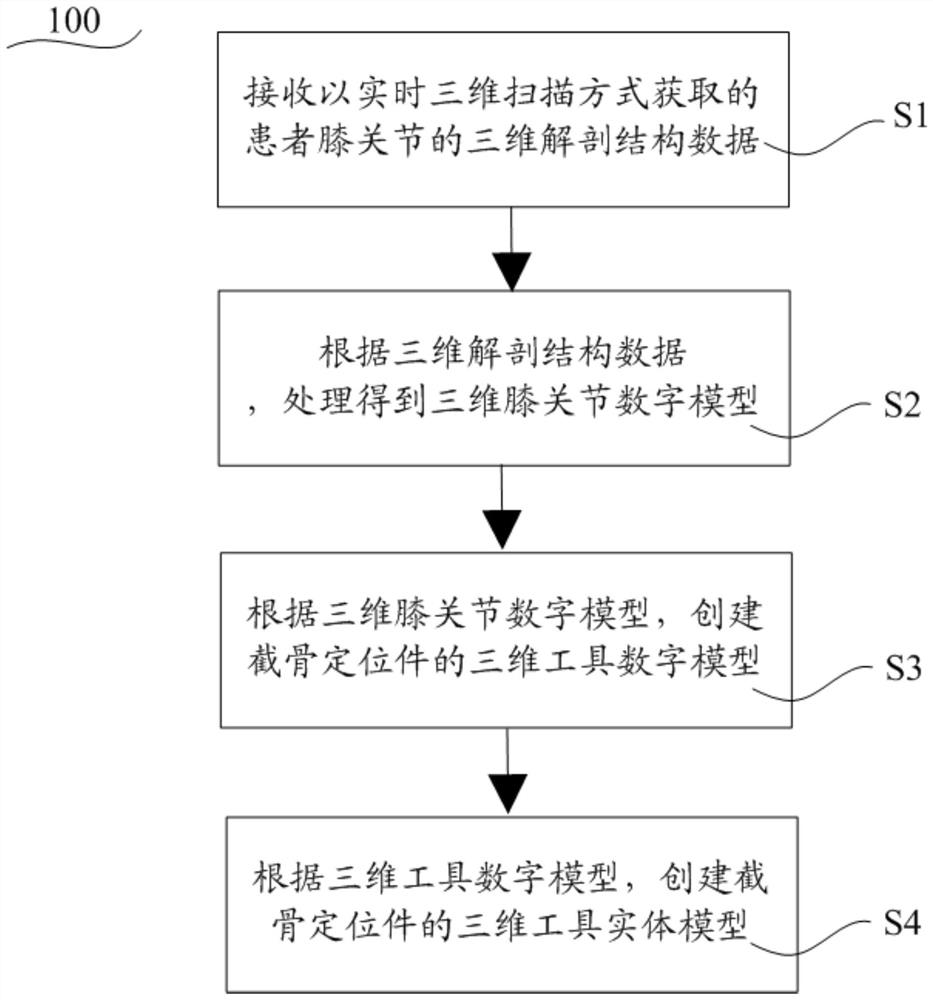

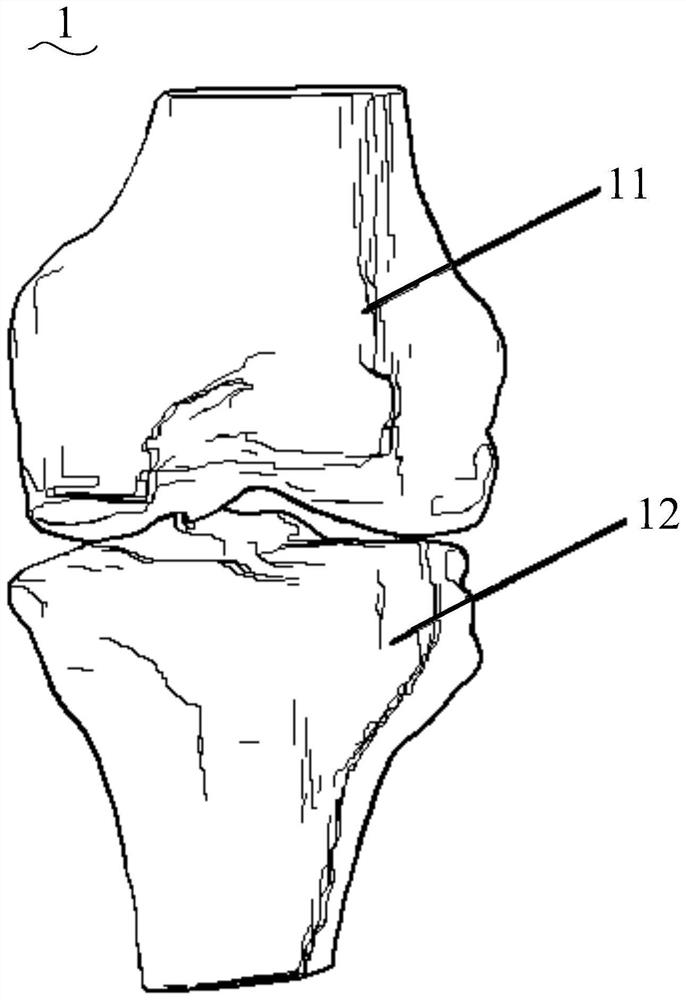

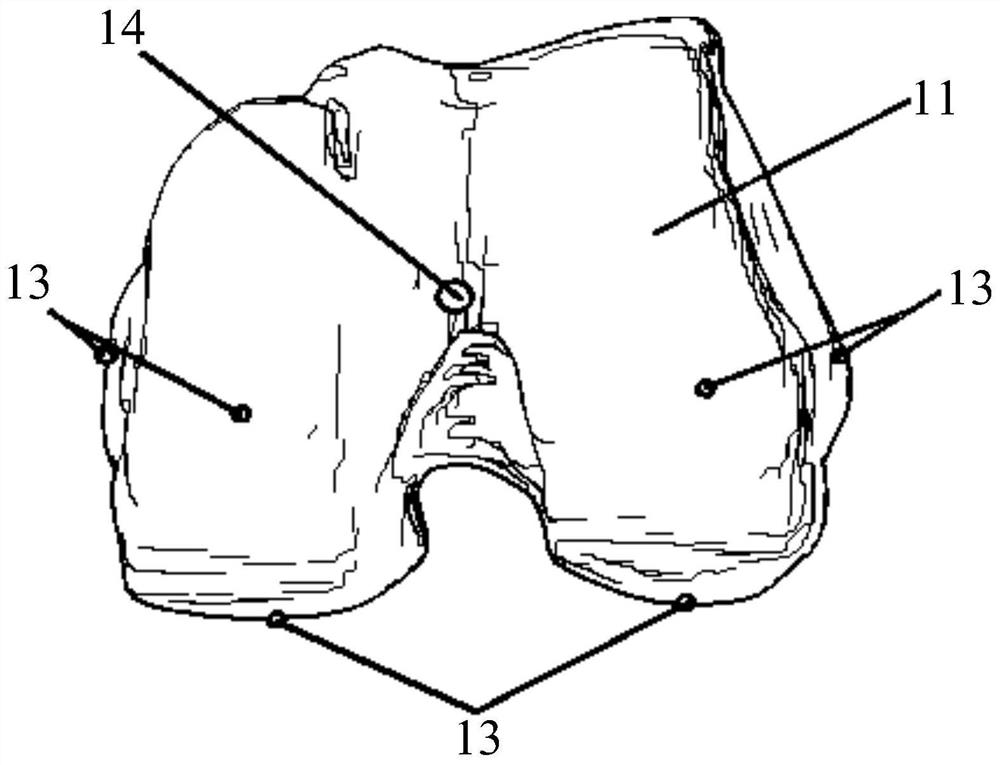

[0097] In order to make the objects, advantages and features of the present invention clearer, the following are combined with the appendix Figures 1 to 15 The knee joint osteotomy tool and its manufacturing system and manufacturing method provided by the present invention will be further described in detail with various specific embodiments. It should be noted that, the accompanying drawings are all in a very simplified form and in inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention.

[0098] As used in this specification and the appended claims, the singular forms "a," "an," and "the" include plural referents unless the content clearly dictates otherwise. As used in this specification and the appended claims, the term "or" is generally employed in its sense including "and / or" unless the content clearly dictates otherwise.

[0099] The present invention provides a customized knee joint oste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com