Prefabricated part comprehensive production line

A technology of prefabricated components and production lines, applied in the direction of manufacturing tools, ceramic molding workshops, auxiliary molding equipment, etc., can solve problems such as unsatisfactory production efficiency, and achieve the effects of saving working time, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described below according to the embodiments shown in the accompanying drawings. It can be thought that embodiment disclosed this time is an illustration in every point, and is not restrictive. The scope of the present invention is not limited by the description of the following embodiments but only by the scope of the claims, and includes the same meaning as the scope of the claims and all modifications within the scope of the claims.

[0034] The structure of the comprehensive production line of prefabricated components of the present invention will be described below in conjunction with specific embodiments.

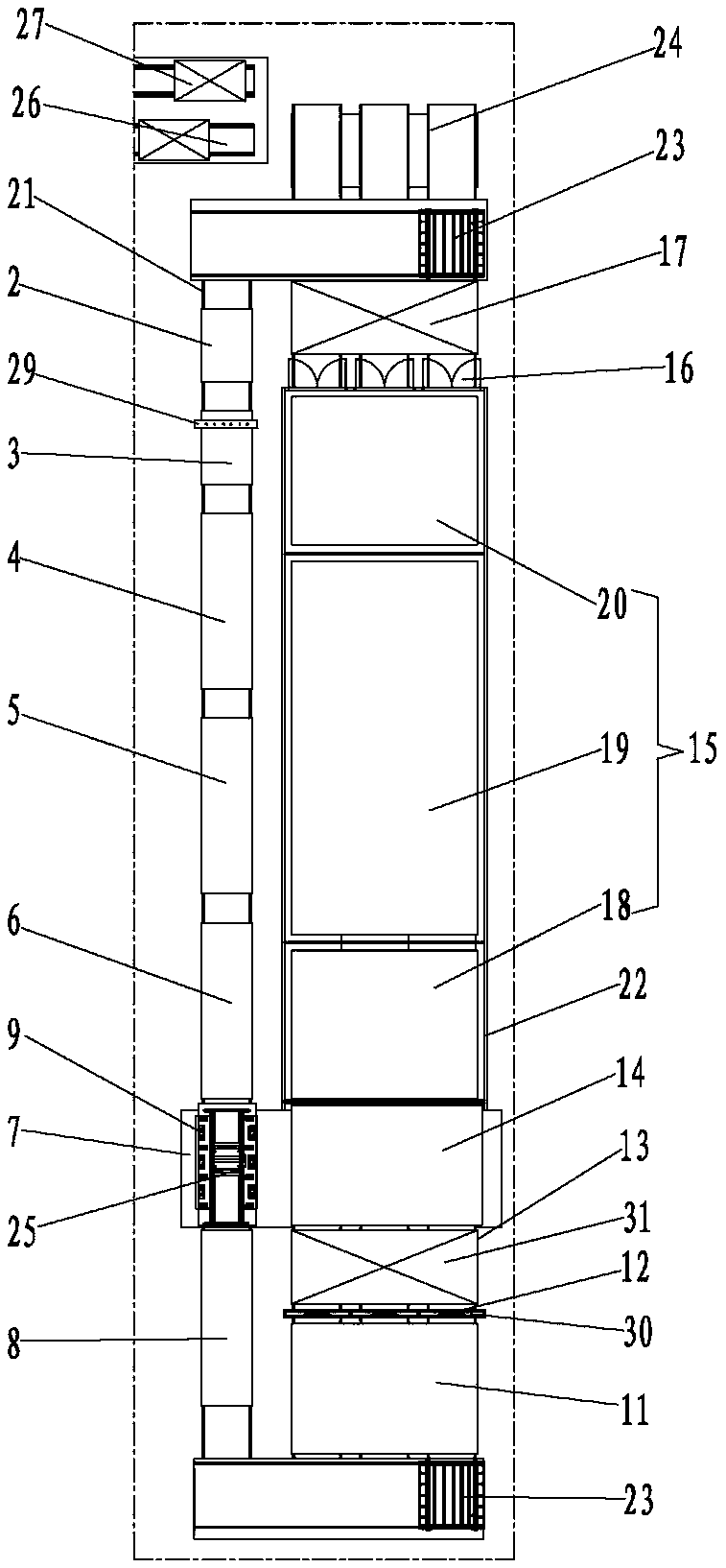

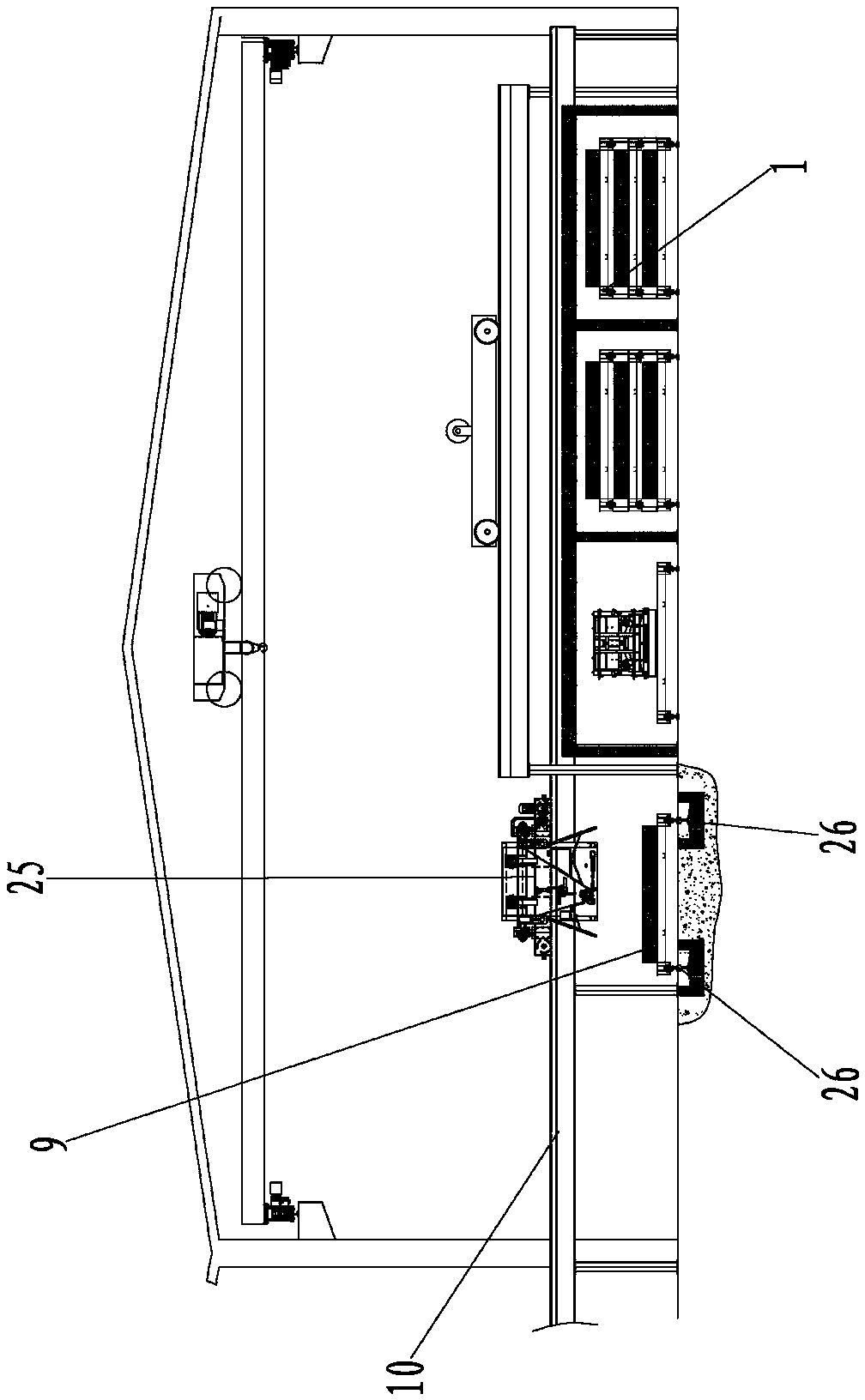

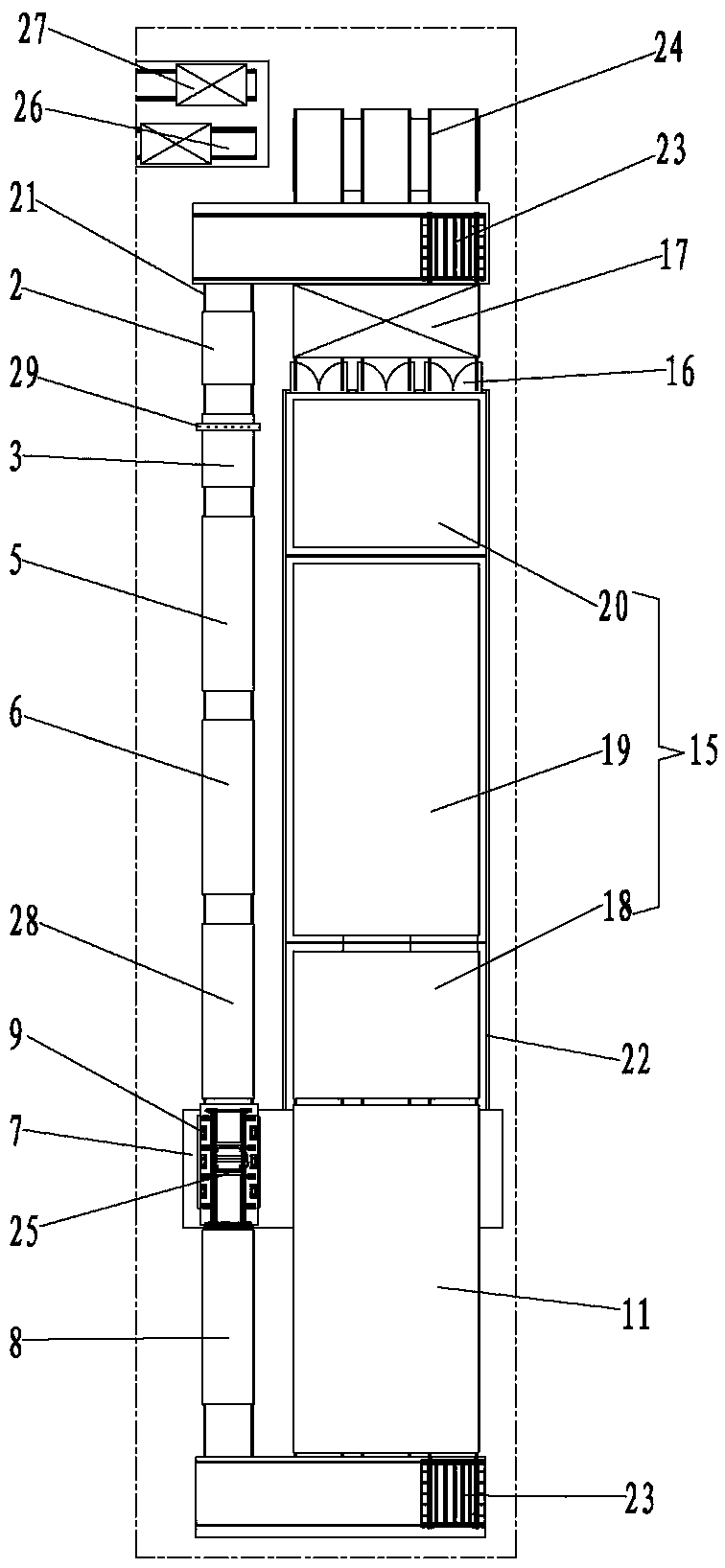

[0035] Such as figure 1 The schematic structural diagram of Embodiment 1 of the integrated prefabricated component production line of the present invention is shown, including at least one working line, at least one maintenance line controlled by the production line control system, and at least one mold trolley 1 for circulating o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com