A kind of production method of bamboo charcoal and carbonization device used in the method

A production method and carbonization technology, applied in the field of materials, can solve the problems of serious pollution, small specific surface area of bamboo charcoal, and low labor productivity, and achieve the effects of high thermal efficiency, light specific gravity, and improved labor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] It should be added that bamboo charcoal is prepared by the traditional carbonization pyrolysis method. The preparation method includes the following steps: cut off the bamboo, put it into a vertical carbonization kettle and burn it at a temperature of 800 ° C, and the carbonization time is 72 hours. After cooling, it is obtained Bamboo charcoal products. During the carbonization process, the overflow gas is collected, and the syngas, bamboo tar and bamboo acetic acid are recovered after cooling.

[0066] The bulk weight of bamboo charcoal powder obtained by this method is less than 400g / L, and the BET specific surface area is also less than 600m 2 / g, and can only be intermittently produced one can by one can, and cannot be operated in a continuous assembly line, with low efficiency and prominent environmental protection problems.

[0067] The method of the present invention is also widely applicable to the preparation of ultra-high specific surface area, high iodine ads...

Embodiment 1

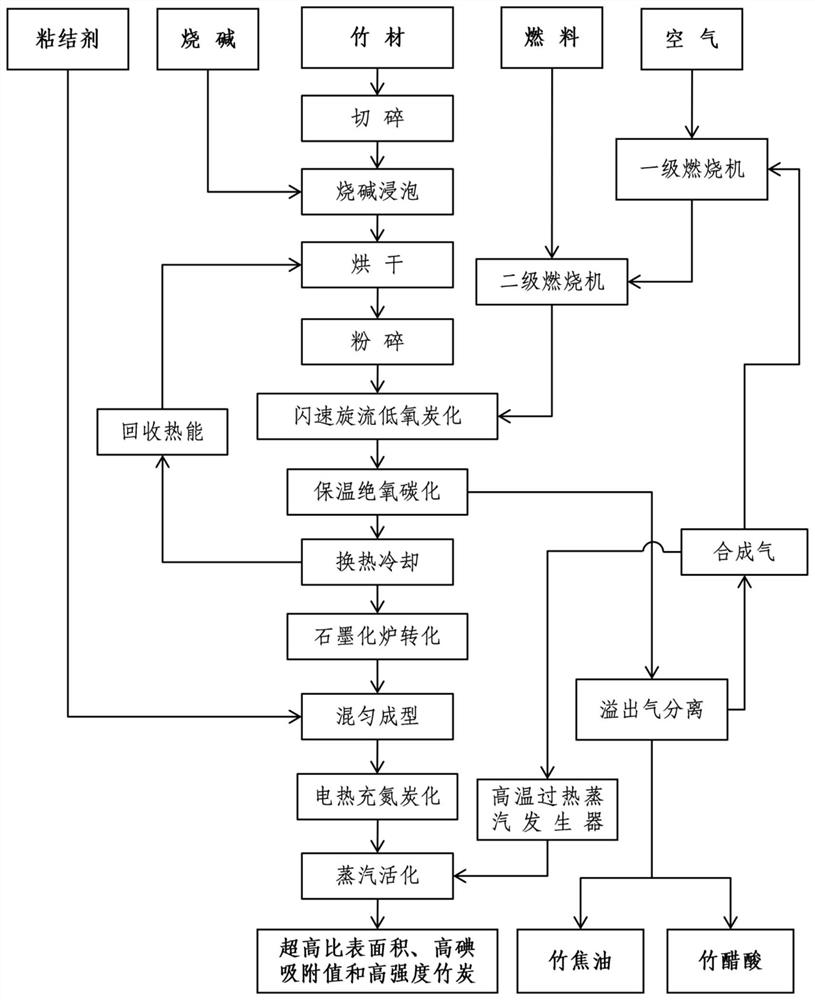

[0071] Such as figure 1 As shown, a new biomass material technology enterprise processes 40,000 tons of moso bamboo over 5 years old (the average moisture content at the factory is 15%). The shape raw material size is 3mm~50mm×3mm~50mm, and the thickness is 1mm~10mm. After arriving at the factory, soak in 15% sodium hydroxide aqueous solution for 24 hours, then bake with recovered hot air at 150°C for 45 minutes, and dry until the moisture content is lower than 0.6%, and the particle size of 100 mesh after crushing is greater than or equal to 85%. . Then flash low-oxygen carbonization at 1000°C for 3 seconds and anaerobic carbonization at 950°C for 60 minutes, and then use cold air as the medium to cool to 55°C by pipeline heat exchange to obtain high The specific surface area of bamboo charcoal powder is 10,000 tons, and the gas overflowed by flash low-oxygen carbonization and anaerobic carbonization is separated by a condenser to recover syngas of 11.9 million Nm 3 , 2,...

Embodiment 2

[0078] A bamboo industry cooperative runs its own bamboo charcoal enterprise, processing 12,500 tons of Cizhu over 3 years old each year (the average moisture content at the factory is 20%). . After arriving at the factory, soak in 20% sodium hydroxide aqueous solution for 24 hours, then bake with recovered hot air at 180°C for 30 minutes until the moisture content is lower than 2%, and the particle size after crushing is less than 1mm. Then flash low-oxygen carbonization at 950°C for 7 seconds and anaerobic carbonization at 900°C for 50 minutes, and then use cold air as the medium to cool to 60°C by pipeline heat exchange to obtain a particle size of 50 mesh greater than or equal to 65% high ratio The surface area of bamboo charcoal powder is 3,000 tons, and the gas overflowed by flash low-oxygen carbonization and anaerobic carbonization is separated by a condenser to recover synthesis gas of 3.4 million Nm 3 , 550 tons of bamboo tar and 3,500 tons of bamboo acetic acid. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com