Suspension type liquid fertilizer and preparation method thereof

A technology for suspending liquids and liquids, which is applied in the direction of liquid fertilizers, nitrogen fertilizers, and phosphate fertilizers. It can solve the problems of low nutrient content of clear liquid fertilizers and low efficiency of long-distance transportation, and achieve high suspension capacity, strong hydrophilic water retention, and strong emulsification. Stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

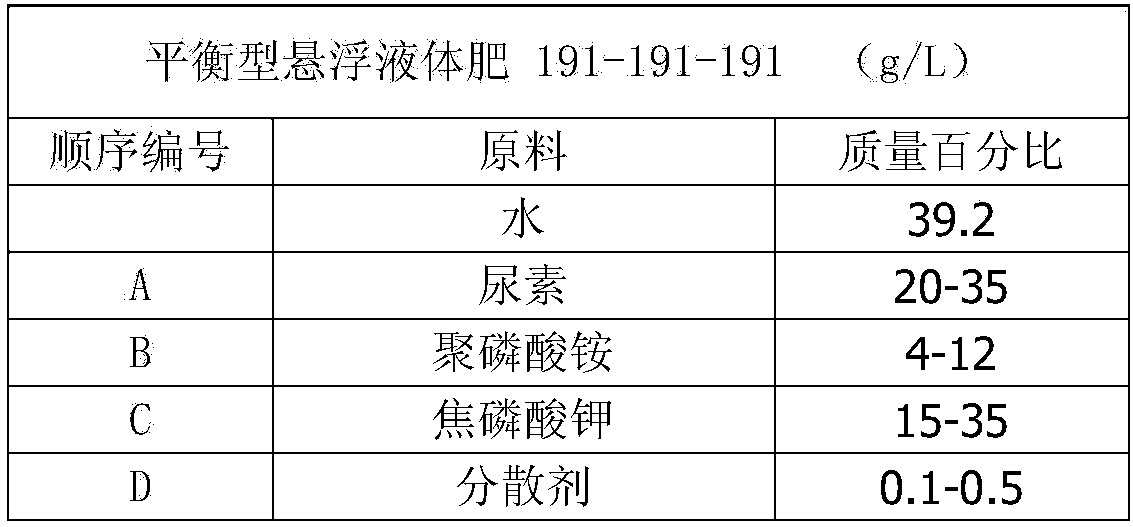

[0018] Balanced suspension liquid fertilizer and preparation method thereof:

[0019]

[0020] According to the ratio in the ingredient list, put the corresponding amount of water into the combined agitator reactor, control the temperature at 30°C-60°C, the stirring speed at 15rpm-90rpm, and the shearing speed at 1500rpm- 4500 rpm. For the structure of the combined agitator reactor, please refer to the patent application of the applicant entitled "A Combined Agitator Reactor Device"; the Chinese patent with the publication number CN206103931U.

[0021] According to the ratio in the ingredient list, according to the order of A, B, C, D, put other raw materials into the combined mixer reactor in a spoonful, uniform and dispersed manner.

[0022] After the feeding is finished, cool while stirring and shearing for 30 minutes.

[0023] After the product is tested, its N, P 2 o 5 、K 2 O concentrations were 191g / L, 191g / L, and 191g / L, respectively.

[0024] The components an...

Embodiment 2

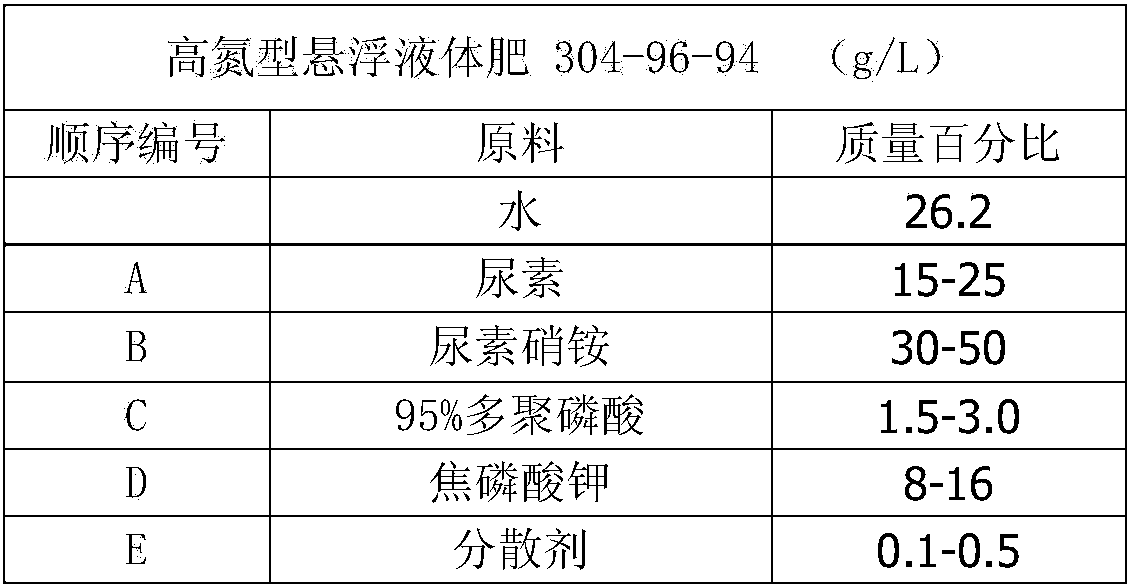

[0026] High-nitrogen suspension liquid fertilizer and preparation method thereof:

[0027]

[0028] According to the ratio in the ingredient list, put the corresponding amount of water into the combined agitator reactor, control the temperature at 30°C-60°C, the stirring speed at 15 rpm-90 rpm, and the shearing speed at 1500 rpm-4500 rpm.

[0029] According to the ratio in the ingredient list, according to the order of A, B, C, D, E, put other raw materials into the combined mixer reactor in a spoonful, uniform and dispersed manner.

[0030] After the feeding is finished, cool while stirring and shearing for 30 minutes.

[0031] After the product is tested, its N, P 2 o 5 、K 2 O concentrations were 304g / L, 96g / L, and 94g / L, respectively. The components and mass percentages of the raw material E (dispersant) are: 80% guar gum, 15% xanthan gum and 5% glucose.

Embodiment 3

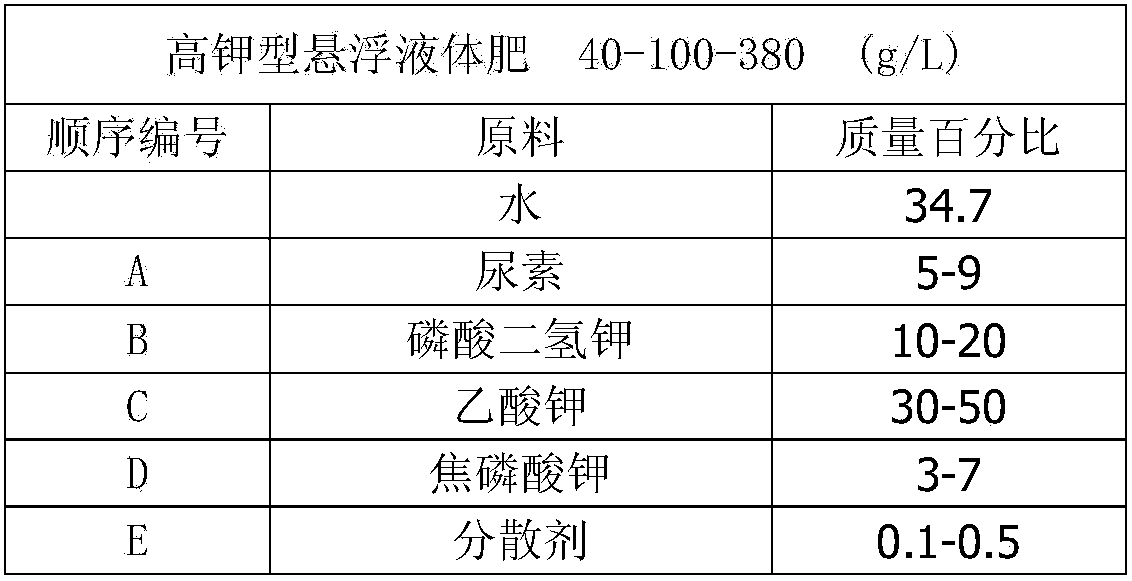

[0033] High-potassium suspension liquid fertilizer and preparation method thereof:

[0034]

[0035] According to the ratio in the ingredient list, put the corresponding amount of water into the combined agitator reactor, control the temperature at 30°C-60°C, the stirring speed at 15 rpm-90 rpm, and the shearing speed at 1500 rpm-4500 rpm.

[0036] According to the ratio in the ingredient list, according to the order of A, B, C, D, E, put other raw materials into the combined mixer reactor in a spoonful, uniform and dispersed manner.

[0037] After the feeding is finished, cool while stirring and shearing for 30 minutes.

[0038] After the product is tested, its N, P 2 o 5 、K 2 O concentrations were 40g / L, 100g / L, and 380g / L, respectively. The components and mass percentages of the raw material E (dispersant) are: 80% guar gum, 15% xanthan gum and 5% glucose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com