Fireproof paint and preparation method thereof

A technology of fire-resistant coatings and raw materials, applied in fire-resistant coatings, polycarbonate coatings, coatings, etc., can solve problems such as poor fire-proof performance, affecting the protective effect of coatings, and peeling off of the substrate surface, achieving excellent cold and frost resistance, Effect of long-term effective protection and improvement of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

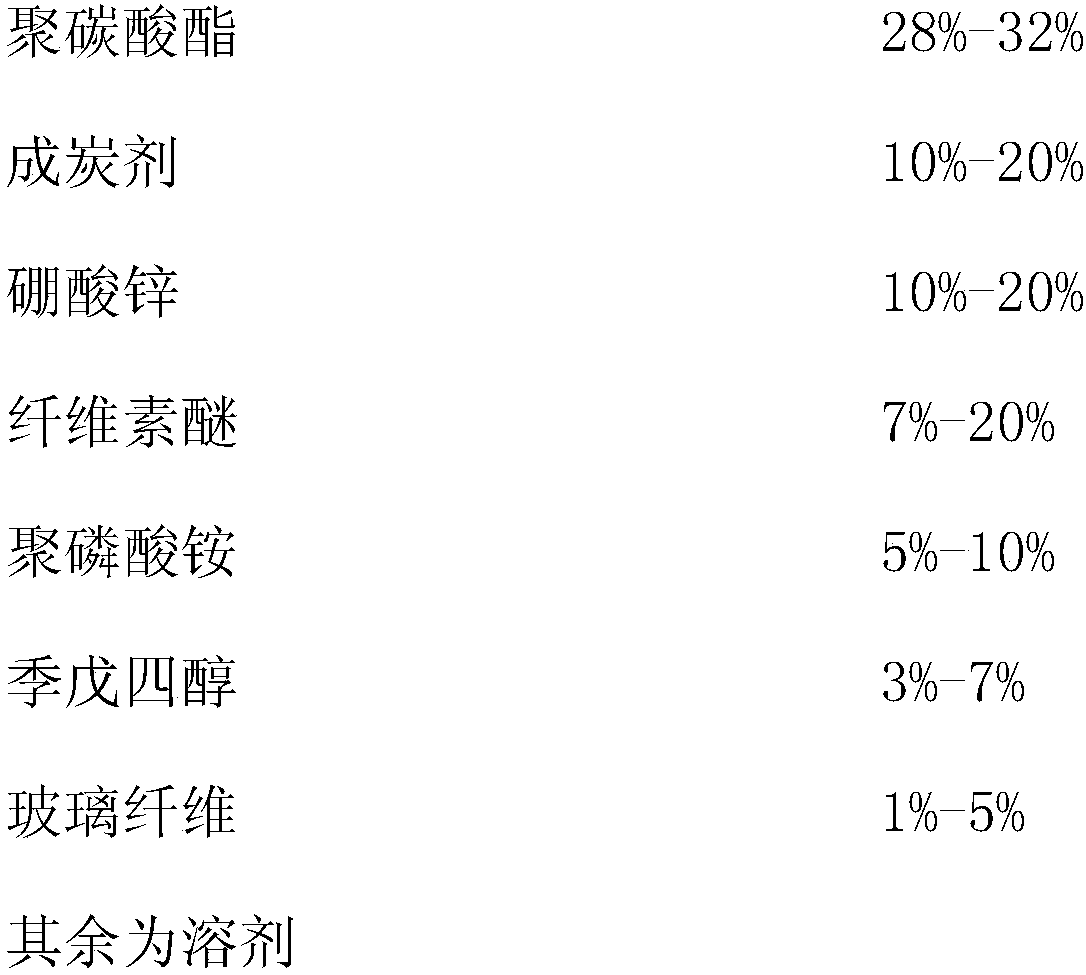

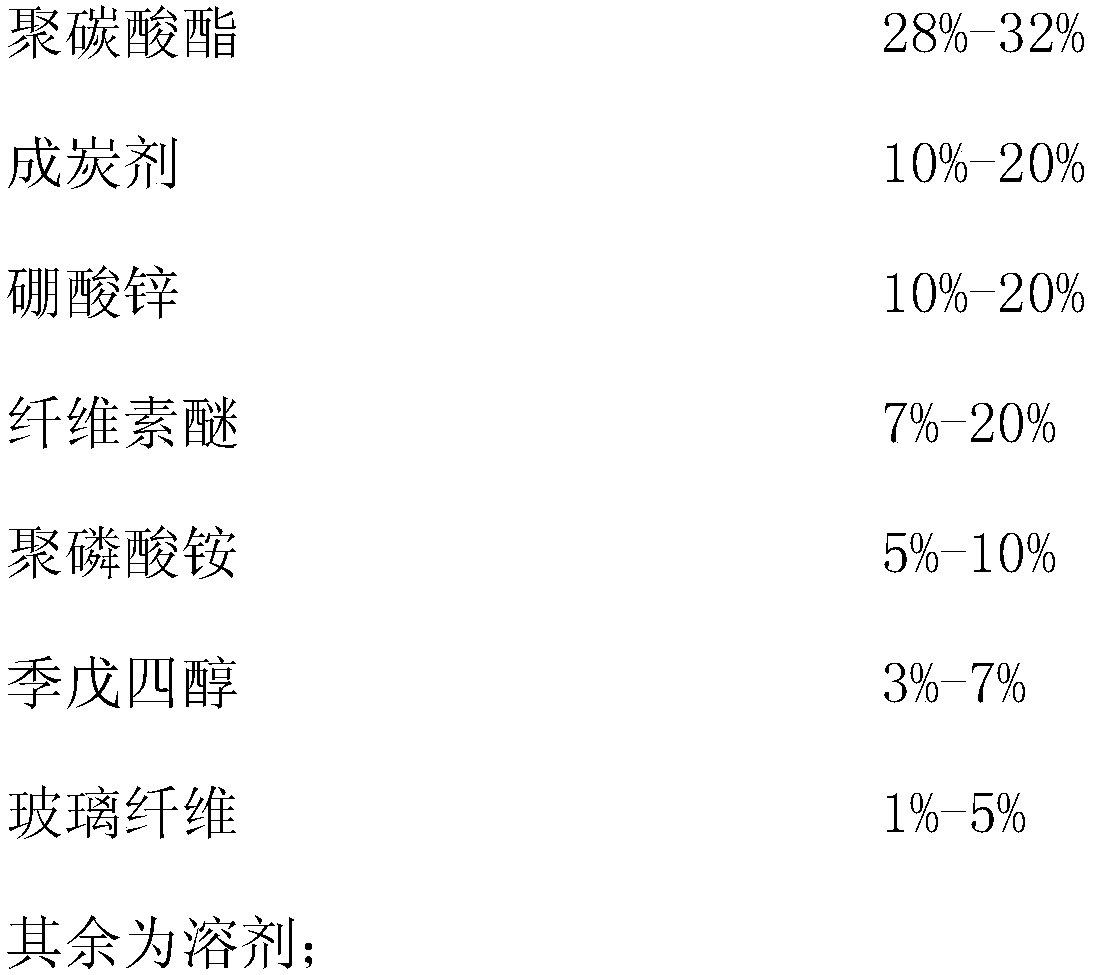

[0029] A kind of fireproof coating that the present invention proposes, the percentage by weight of each raw material is polycarbonate 28%, carbon forming agent 20%, zinc borate 10%, cellulose ether 7%, ammonium polyphosphate 5%, pentaerythritol 3%, glass fiber 1%, and the rest is solvent; in addition: 4% of curing agent and 4% of light stabilizer (the weight percentage is based on the weight of the above raw materials).

[0030] The present invention also proposes a kind of preparation method of fireproof coating, comprises the following steps:

[0031] Mix ammonium polyphosphate, zinc borate, ammonium polyphosphate, glass fiber, curing agent and solvent, stir evenly, and grind at a high speed to a fineness of 18 μm to obtain a color paste;

[0032] S2, take cellulose ether, char forming agent, pentaerythritol and light stabilizer and stir and mix, stir evenly, add the color paste prepared in S1, and disperse at high speed for 15 minutes, which is the product of the present i...

Embodiment 2

[0034] A kind of fireproof coating that the present invention proposes, the percentage by weight of each raw material is polycarbonate 29%, carbon forming agent 18%, zinc borate 12%, cellulose ether 10%, ammonium polyphosphate 6%, pentaerythritol 4%, glass fiber 2%, and the rest is solvent; in addition: 5% of curing agent and 3% of light stabilizer (the weight percentage is based on the weight of the above raw materials).

[0035] The present invention also proposes a kind of preparation method of fireproof coating, comprises the following steps:

[0036] Take ammonium polyphosphate, zinc borate, ammonium polyphosphate, glass fiber, curing agent and solvent and mix them, after stirring evenly, perform high-speed grinding to a fineness of 20 μm to obtain a color paste;

[0037] S2, take cellulose ether, char forming agent, pentaerythritol and light stabilizer and stir and mix, stir evenly, add the color paste prepared in S1, and disperse at high speed for 15 minutes, which is t...

Embodiment 3

[0039] A kind of fireproof coating that the present invention proposes, the percentage by weight of each raw material is polycarbonate 30%, carbon forming agent 16%, zinc borate 14%, cellulose ether 13%, ammonium polyphosphate 7%, pentaerythritol 5%, glass fiber 3%, and the rest is solvent; in addition: 6% of curing agent and 3% of light stabilizer (the weight percentage is based on the weight of the above raw materials).

[0040] The present invention also proposes a kind of preparation method of fireproof coating, comprises the following steps:

[0041] Take ammonium polyphosphate, zinc borate, ammonium polyphosphate, glass fiber, curing agent and solvent and mix them, after stirring evenly, perform high-speed grinding to a fineness of 20 μm to obtain a color paste;

[0042] S2, take cellulose ether, char forming agent, pentaerythritol and light stabilizer and stir and mix, stir evenly, add the color paste prepared in S1, and disperse at high speed for 15 minutes, which is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com