A kind of organosilicon gel material for power battery case sealing and preparation method thereof

A technology for power batteries and gel materials, which is applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as difficulty in applying power battery box sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

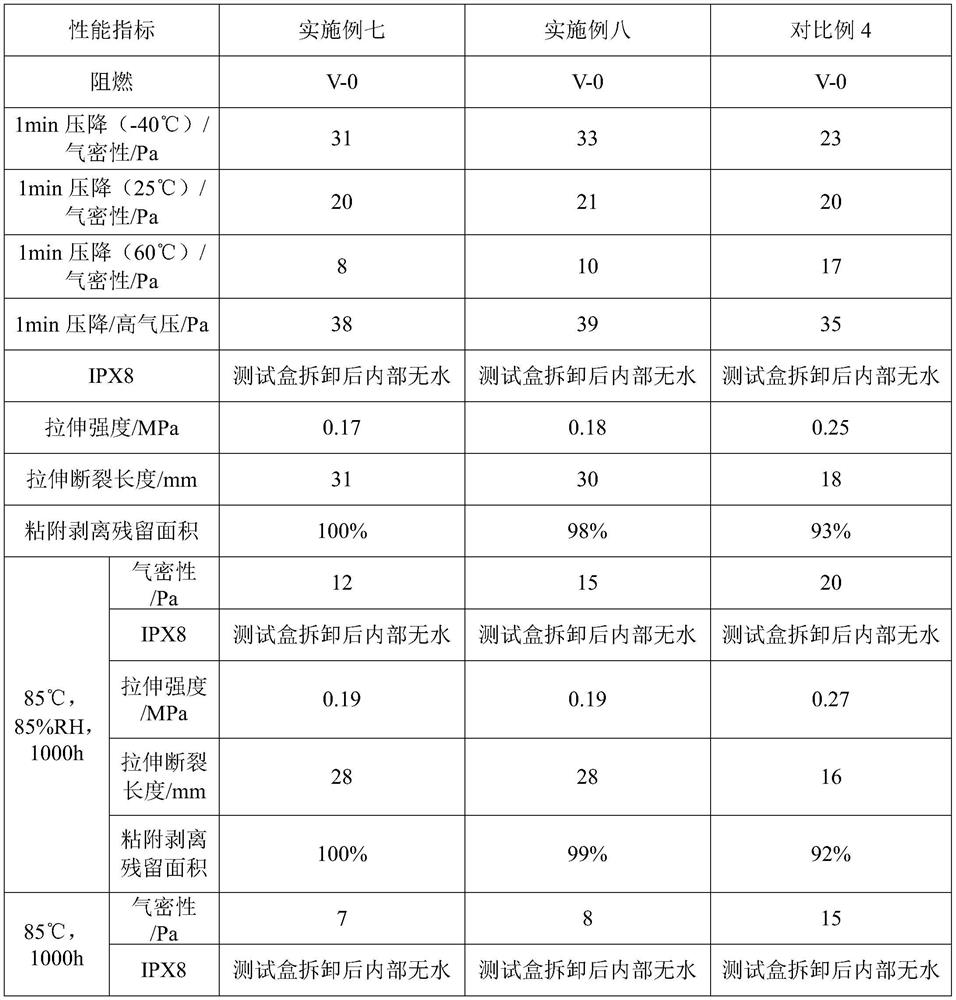

Examples

Embodiment 1

[0038] The preparation of embodiment one base material

[0039] 85 parts of straight-chain vinyl polydimethylsiloxane with a viscosity of 40000mpa·s and a vinyl content of 0.06wt%, and straight-chain vinyl polydimethylsiloxane with a viscosity of 500mpa·s and a vinyl content of 0.4wt% 15 parts of dimethyl siloxane, 80 parts of aluminum hydroxide with an average particle size of 3 μm were added to a vacuum kneader and mixed evenly, and then dehydrated and blended for 60 minutes under the conditions of a temperature of 140 ° C and a vacuum of -0.08 MPa to obtain Binder.

Embodiment 2

[0040] The preparation of embodiment two base material

[0041] 80 parts of straight-chain vinyl polydimethylsiloxane with a viscosity of 60000mpa·s and a vinyl content of 0.05wt%, and straight-chain vinyl polydimethylsiloxane with a viscosity of 1000mpa·s and a vinyl content of 0.25wt% 20 parts of dimethylsiloxane and 60 parts of magnesium hydroxide with an average particle size of 10 μm are added to a vacuum kneader and mixed evenly, and then dehydrated and blended for 60 minutes at a temperature of 120 ° C and a vacuum of -0.08 MPa to obtain Binder.

Embodiment 3

[0044] Example three A component

[0045] Component A includes the base material of Example 1 and a platinum catalyst, wherein the base material is 100 parts, the platinum catalyst is a vinyl siloxane complex of chloroplatinic acid, and the mass of platinum in the platinum catalyst is 15 ppm of the mass of component A.

[0046] The preparation method of component A: add a platinum catalyst to the base material prepared in Example 1, and stir evenly to prepare component A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com