Dyeing-finishing pretreatment technology capable of recycling waste water

A technology of pre-treatment and pre-treatment solution, which is applied in the field of dyeing and finishing pre-treatment process to achieve the effects of reducing production costs, saving water resources and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

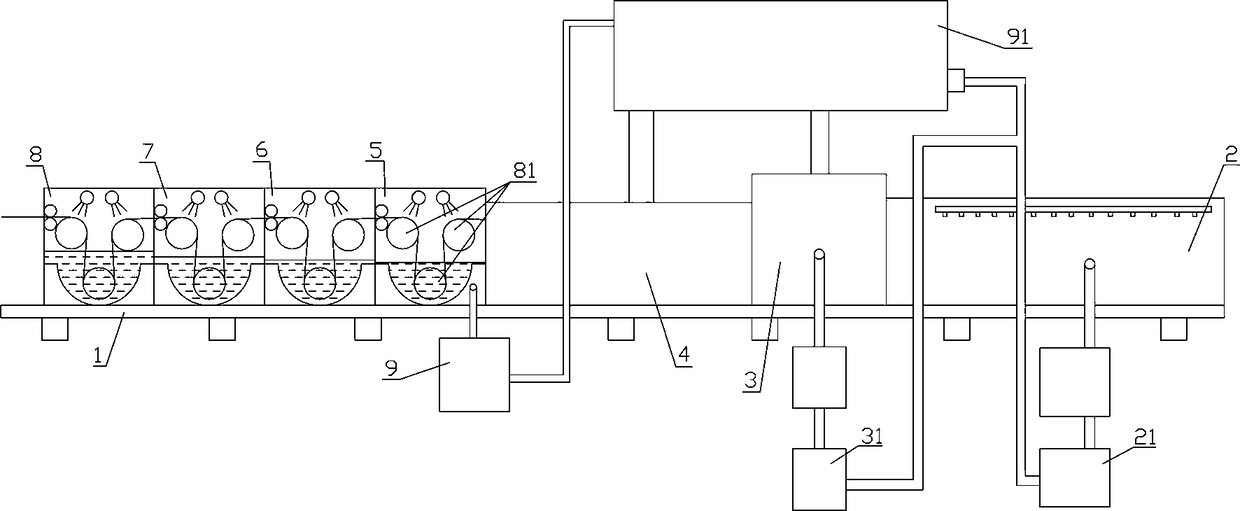

[0014] Such as figure 1 As shown, a dyeing and finishing pretreatment process that can reuse wastewater, the process steps are as follows: firstly, the fabric is sent to the open-width scouring machine 2 for scouring, and the pretreatment liquid during scouring uses bugong tea saponin As a pre-treatment aid; the fabric is boiled and rolled out of excess moisture and then enters the padding machine 3 for padding treatment; the fabric is steamed in the steam box 4 after the padding process is completed and the excess moisture is rolled out. In the example, the top of the steam box 4 is provided with an insulating layer that can prevent condensation water from being produced, so as to prevent the top of the steam box 4 from generating condensation water and dripping on the fabric when the steam box 4 is working, because if any condensation w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com