Positive and negative pressure enhanced drainage shaft structure for precipitation of landfill site and construction method

A landfill, positive and negative pressure technology, applied in infrastructure engineering, construction, etc., can solve problems such as poor pumping effect of pumping shafts, and achieve the effect of reasonable structure, good air tightness, and air tightness assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

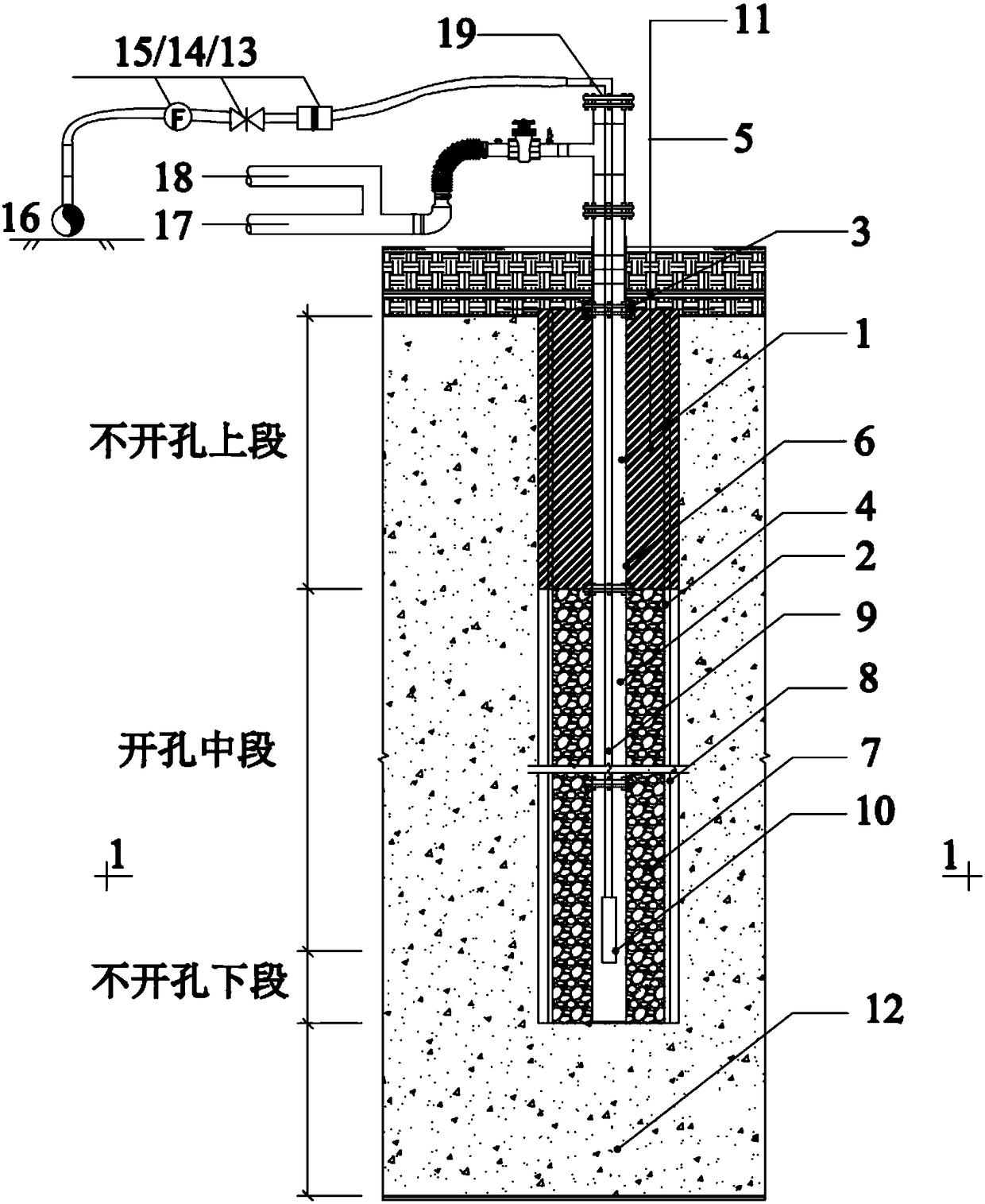

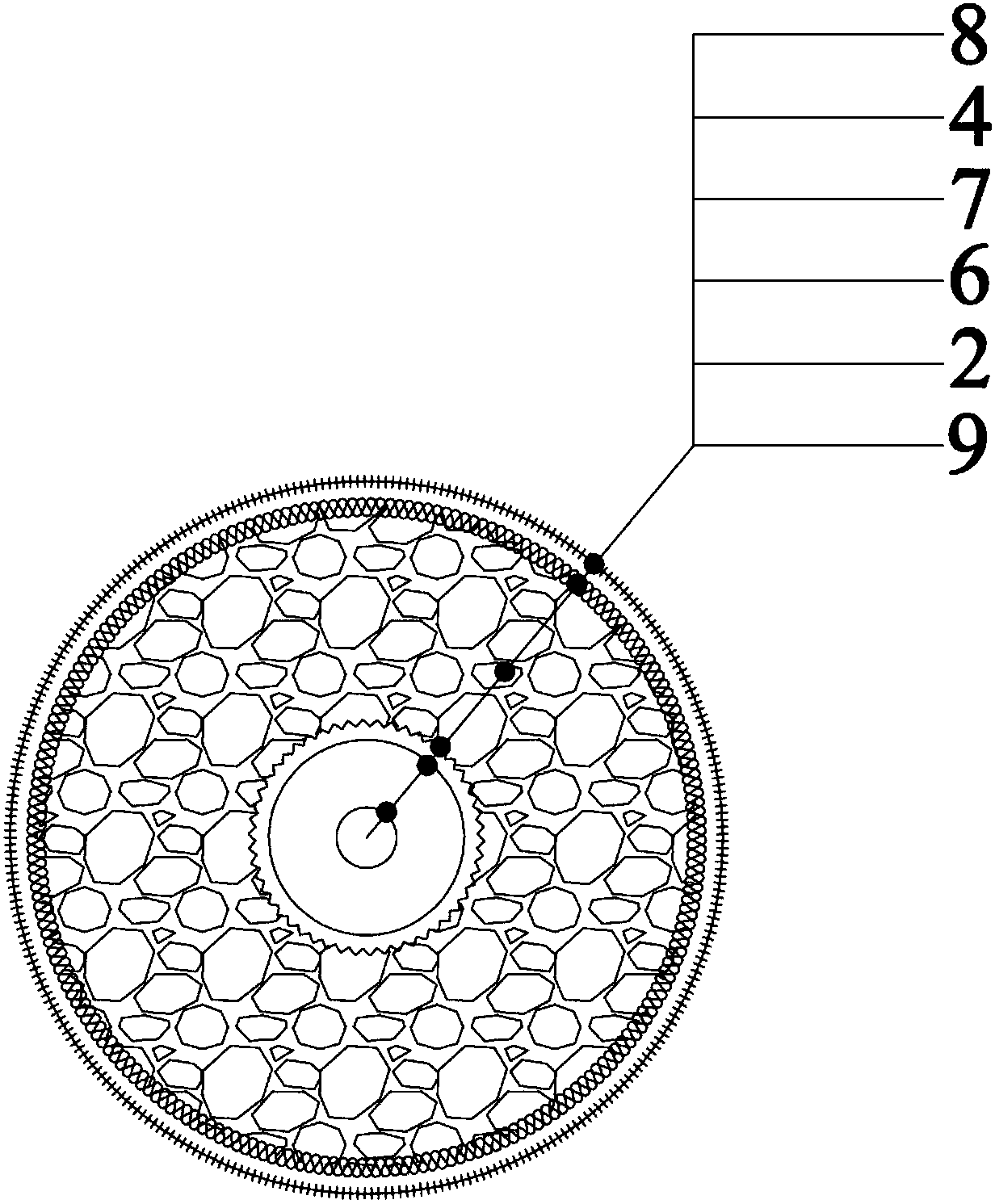

[0031] Such as figure 1 , 2 As shown, the upper section of the positive and negative pressure enhanced suction shaft well pipe of the present invention is a galvanized steel pipe 1 without openings, and as a negative pressure suction sealing section, it is filled with a mass fraction of 5%-20% between the surrounding garbage dump body 12 The compacted clay 5 of bentonite is sealed; the middle section is a perforated galvanized steel pipe 2, which is used as the leachate inflow section; the lower section is a galvanized steel pipe without openings, which is used as a sand settling section; the bottom is blocked; the top of the well pipe is blocked by plugging The flange blind plate 19 is sealed; the middle and lower sections of the well pipe are filled with anti-filter materials between the galvanized steel pipes and the surrounding g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com