Method and system for diagnosing online part faults of turbofan engines

A turbofan engine, fault diagnosis technology, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

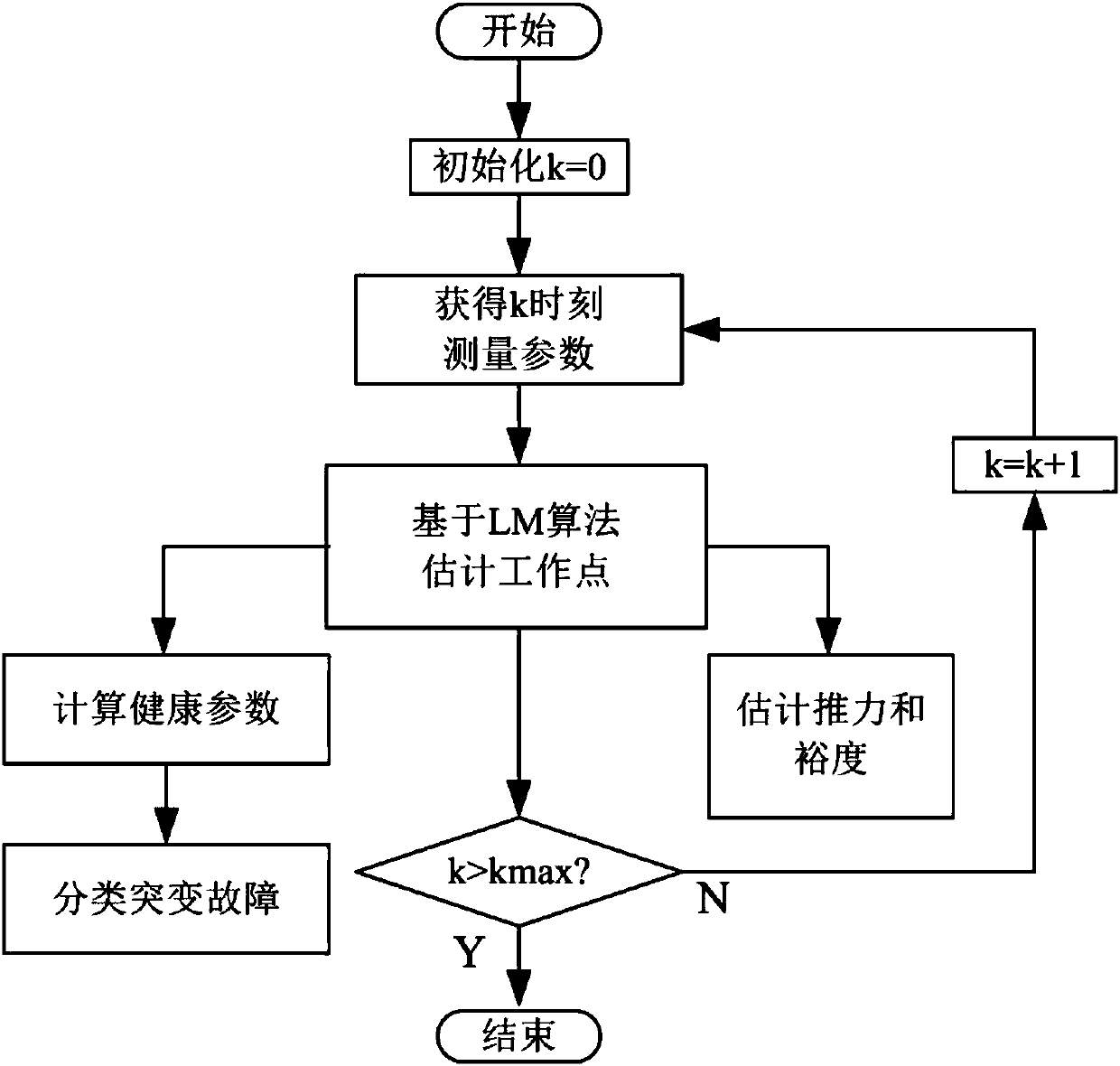

[0093] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in further detail below in conjunction with specific embodiments.

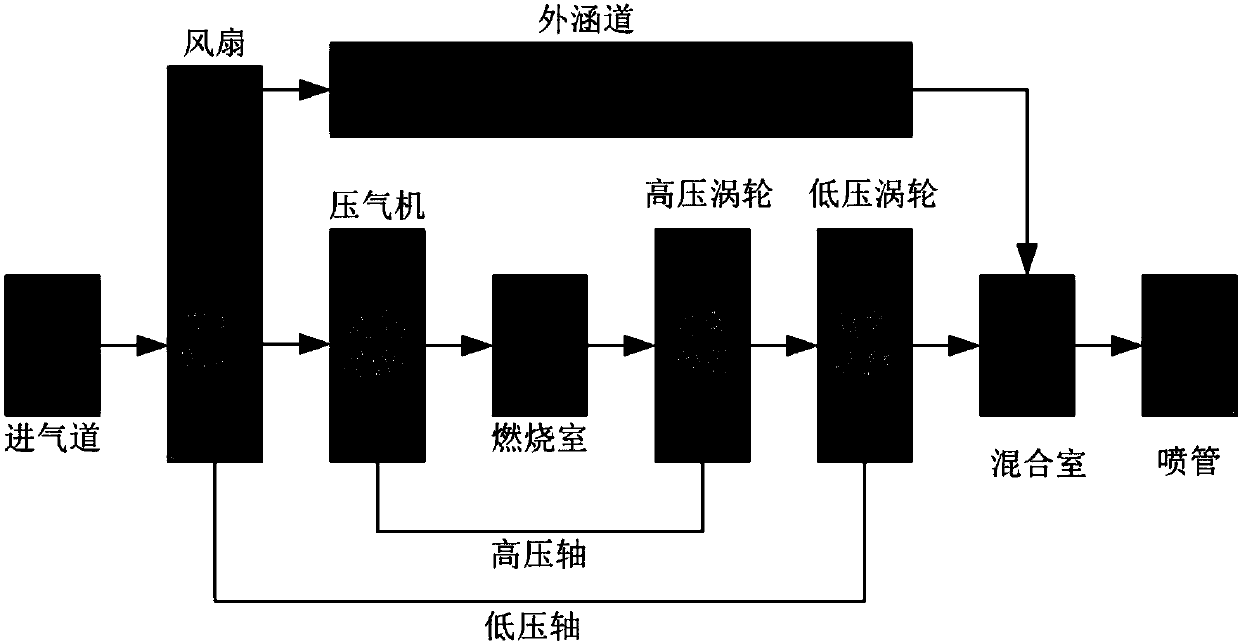

[0094] The embodiment of the present invention takes the health diagnosis of gas circuit components of a certain type of turbofan engine as an example, where the turbofan engine is replaced by a nonlinear component-level reference model, and the iteration method of this component-level model is the Newton-Raphson method.

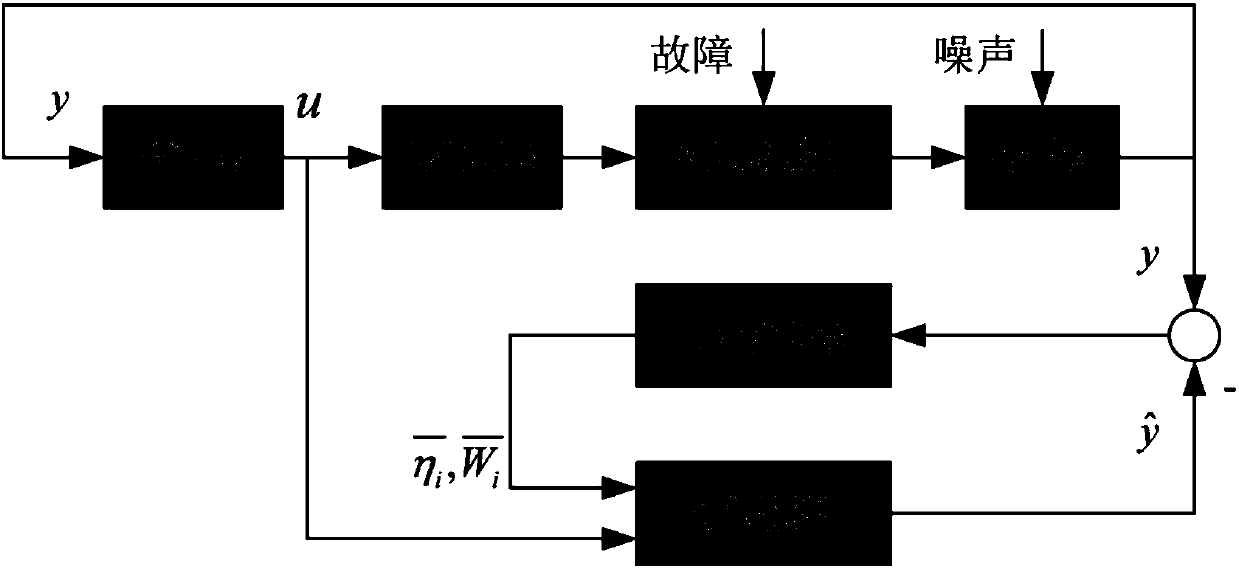

[0095]In order to estimate unmeasurable health parameters and thrust margin performance parameters, the measurable parameters of the turbofan engine used in the present invention include rotating speed, temperature and pressure at the outlet of some parts. In order to test the effectiveness of the present invention in non-Gaussian systems, Rayleigh noise was added to the engine model as process noise, and the standard deviation of Ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com