High-voltage electric wire deicing device capable of realizing automatic deicing

A high-voltage wire and mobile device technology, applied in the field of high-voltage wire deicing devices, can solve problems such as damage to the power supply network, the device cannot be maintained for a long time, and the impact on production and life, and achieves a simple and practical mechanism, better deicing effect, and reduced total The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

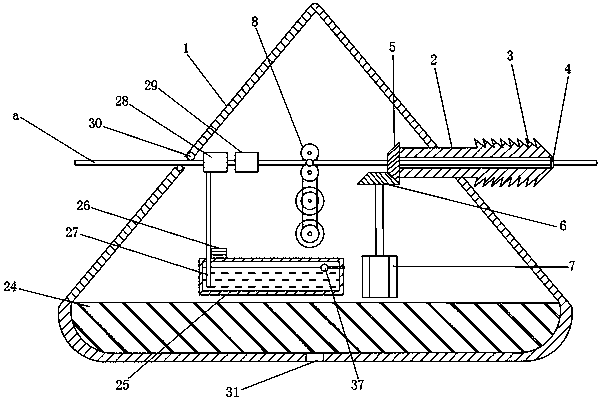

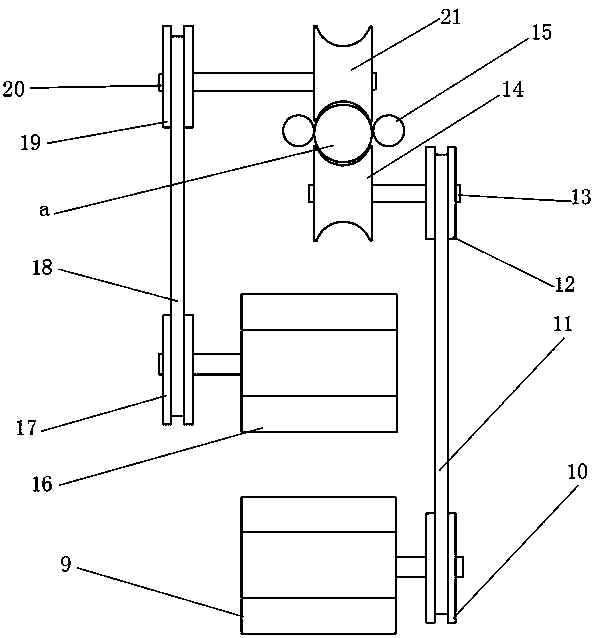

[0027] Embodiment 1: (without steel ball 30; without baffle 1 and baffle 2)

[0028] A high-voltage wire deicing device capable of automatic deicing, comprising a housing 1, a deicing drill bit 2, a moving device 8, a thermal deicing device 29, an antifreeze application device 28, and a base 32; the housing 1 is hollow inside, wrapped Mobile device 8, thermal deicing device 29 and antifreeze smearing device 28; The shell wall of described housing 1 is provided with electric heating wire 1 45; The central part of described deicing drill bit 2 is provided with through hole; The drill bit 2 is divided into two halves from the center through hole; the tail and the head of the deicing drill bit 2 are respectively provided with a screw hole 1 22 and a screw hole 2 23; the screw hole 2 23 is a countersunk screw hole; The second half of the ice drill bit 2 is a smooth cylindrical structure wrapped in the shell 1; the front half of the deicing drill bit 2 is provided with a drill threa...

Embodiment 2

[0035] Embodiment 2: (without steel ball 30; with baffle 1 and baffle 2)

[0036] Embodiment 2 is basically the same in structure and principle as Embodiment 1, except that the wire inlet hole 44 is provided with a wire protection steel ball 30 . The wire-protecting steel ball 30 can ensure that the high-voltage wire a does not directly contact the housing 1, and protects the high-voltage wire a from being scratched.

Embodiment 3

[0037] Embodiment 3: (with wire protection steel ball 30; without baffle 1 and baffle 2)

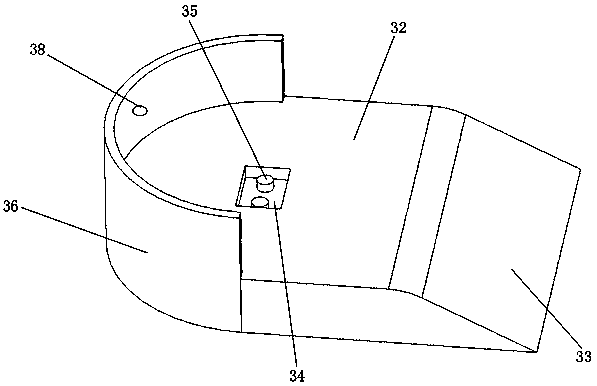

[0038] The third embodiment is basically the same in structure and principle as the first embodiment, except that the top of the charging tank 34 is provided with a baffle plate 1; the charging socket 31 is provided with a baffle plate 2 . The baffle protects the charging tank 34 from falling into ice and snow; when the deicing device enters the base 32 and touches the charging switch 38, the baffle on the charging tank 34 is automatically retracted, and the simple lifting The device raises the charging connector 35; the second baffle plate protects the charging socket 31 from falling into ice and snow; when the charging switch 38 is touched, the second baffle plate retracts automatically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com