Three-phase horizontal spiral centrifuge for oil-water sand separation

A spiral centrifuge, three-phase horizontal technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve problems such as unspecified liquid separation and collection, achieve effective and reliable technical support, and reduce oil content in sand production. , The effect of reducing oil removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

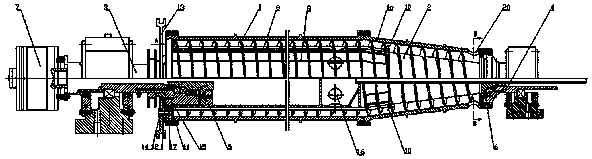

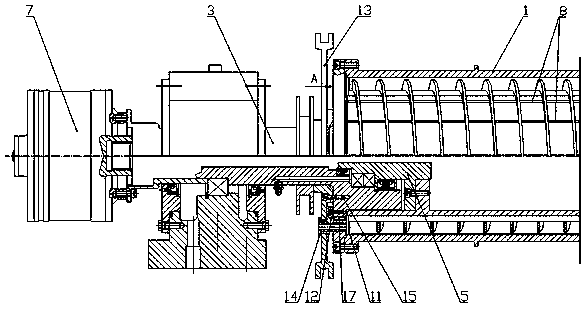

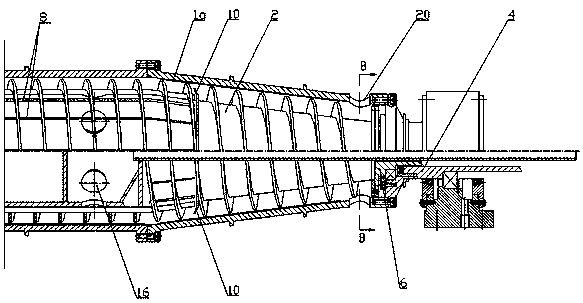

[0026] figure 1 , 2 , 3, 7, and 11 show a structural diagram of a three-phase horizontal screw centrifuge for oil-water-sand separation. In the figure, this oil-water-sand separation three-phase horizontal screw centrifuge includes a drum, a screw conveyor 2, a large end flange 3, a small end flange 4, a left helical journal 5, a right helical journal 6 and a planetary gear Differential 7. The rotary drum includes a column section shell 1 and a cone section shell 1a. In the rotary drum along the radial position, the liquid pool is sequentially composed of light liquid layer oil, heavy liquid layer water and solid sediment layer sand. There are 12 vertical plates 8 welded circumferentially on the wall of the screw conveyor 2, and the blades 9 of the screw conveyor are welded on the vertical plates 8. The length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com