Ultrasonic cleaning sterilization device

A sterilization device and ultrasonic technology, which are applied to water supply devices, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve the problems of low cleaning efficiency, not easy to carry, and bulky, and achieve low manufacturing cost and good cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

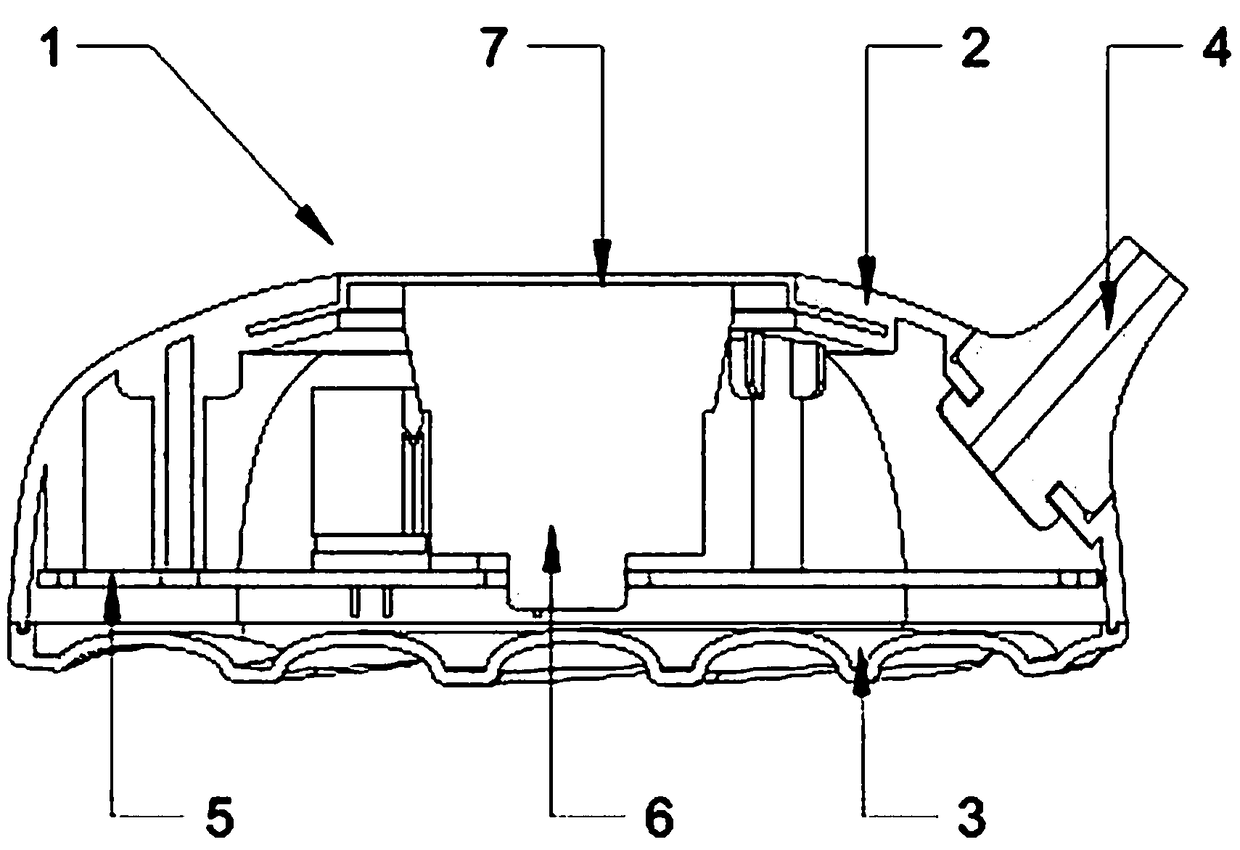

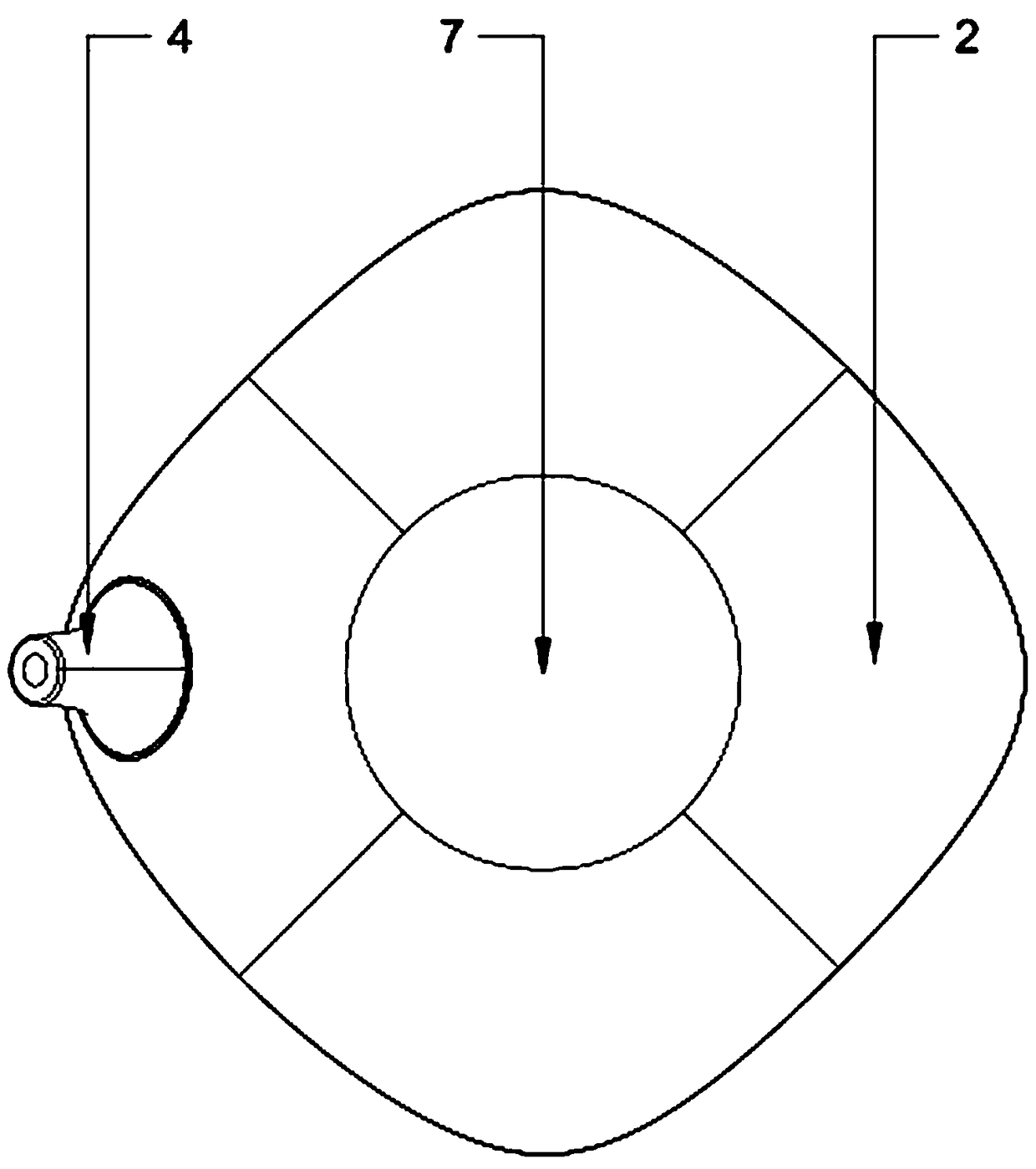

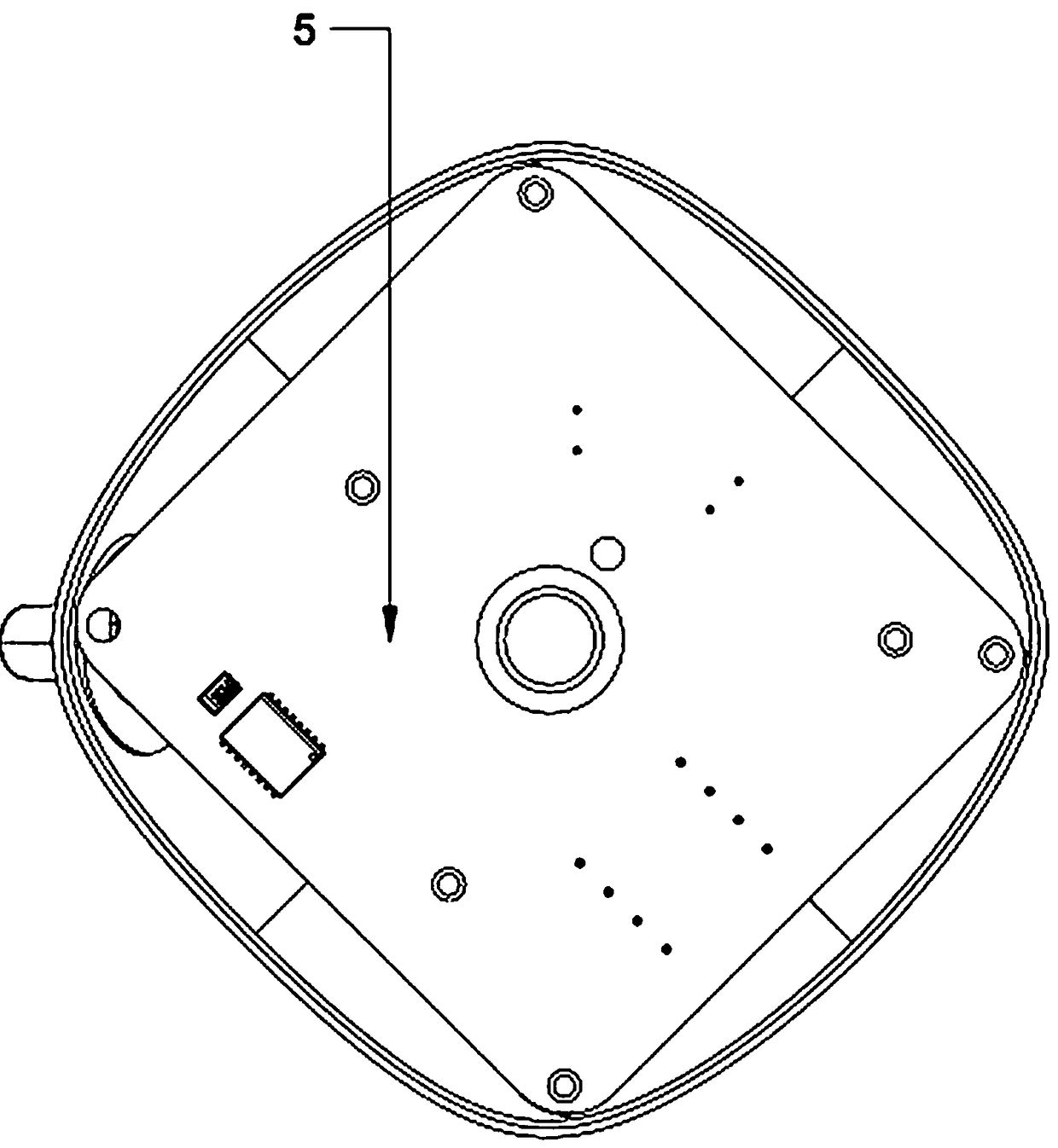

[0022] Such as figure 1 and Figure 5 As shown in , the external structure of the ultrasonic cleaning and sterilization device is mainly composed of a casing, a back cover, a waterproof outlet interface and a vibrating working cap, and the main internal components are a printed circuit board and an ultrasonic transducer. The waterproof conductive circuit is electrically connected with the internal printed circuit board through the waterproof outlet interface. Such as figure 2 As shown, the shell is made of plastic, and the vibrating working cap is directly above it. Since the vibrating working cap is a terminal device for transmitting ultrasonic waves, the vibrating working cap is preferably made of metal with both elasticity and rigid coupling. into, such as stainless steel, titanium alloy, aluminum alloy, etc. The vibrating work cap is integrally manufactured with the sound wave emitter of the ultrasonic transducer during processing, and uses the same material. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com