Back plate for photovoltaic module and solar battery containing back plate

A technology of solar cells and photovoltaic modules, applied in the field of solar cells, to achieve the effects of reducing the probability of occurrence, delaying discoloration, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

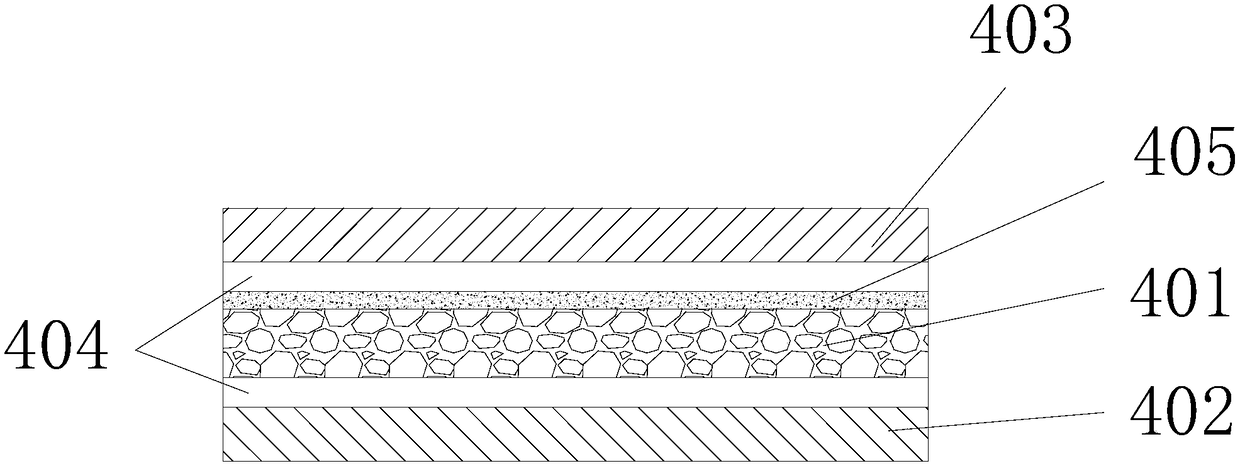

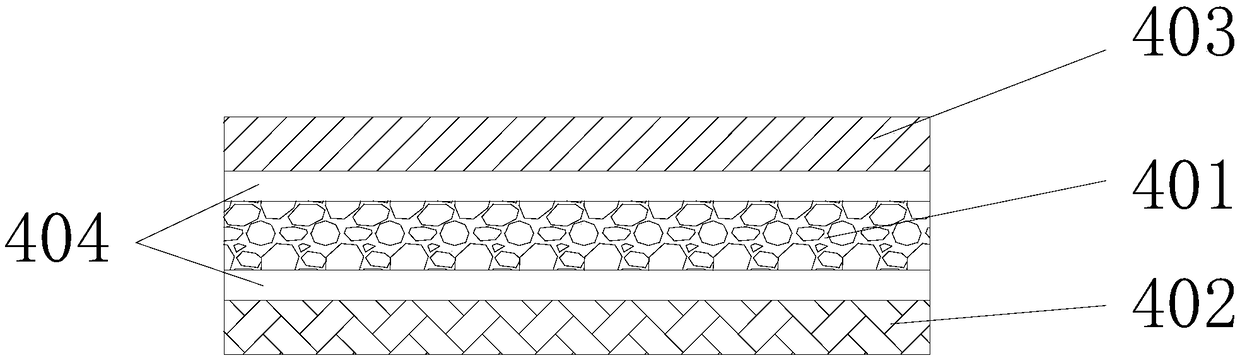

[0039] A backsheet for a photovoltaic module, comprising a PET layer 401 with a thickness of 250 μm; an inorganic water-blocking layer (silicon dioxide layer) 405 with a thickness of 15 μm deposited on the side of the PET layer 401 close to the air, through a 10 μm thick The glue layer 404 is bonded to the outer contact layer (PVDF fluorine layer) 403 with a thickness of 20 μm on the side of the inorganic water blocking layer 405, and is bonded to the side of the PET layer 401 away from the air through the glue layer 404 with a thickness of 10 μm. The encapsulant film contacts the inner contact layer 402 with a thickness of 50 μm.

Embodiment 2

[0047] The difference from Example 1 is that the inorganic water blocking layer is a silicon nitride layer with the same thickness (15 μm).

Embodiment 3

[0049] A backsheet for a photovoltaic module, comprising a PET layer 401 with a thickness of 220 μm; an inorganic water-blocking layer (silicon nitride layer) 405 with a thickness of 10 μm deposited on the side of the PET layer 401 close to the air; The glue layer 404 is bonded to the outer contact layer (PVDF fluorine layer) 403 with a thickness of 18 μm on the side of the inorganic water blocking layer 405, and is bonded to the side of the PET layer 401 away from the air through the glue layer 404 with a thickness of 8 μm. The encapsulant film contacts the inner contact layer 402 with a thickness of 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com