Cooling system for marine diesel engine

A diesel engine and cooling system technology, which is applied to the cooling of the engine, engine components, machines/engines, etc., can solve the problems of large fresh water consumption, short service life, and easy corrosion of the inner cavity of the diesel engine, so as to save fresh water consumption and solve the problem of fresh water consumption of large effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

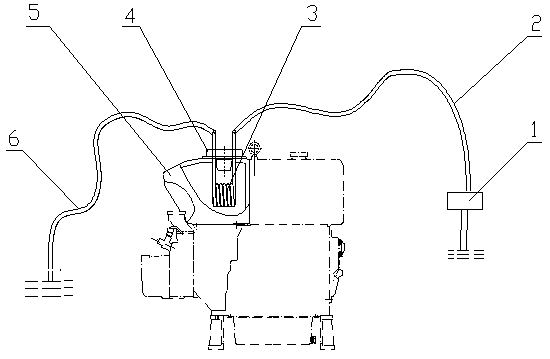

[0015] Embodiment 1: as figure 1 As shown, a marine diesel engine cooling system is applied to ships operating at sea, including a cooling water tank, a water-saving funnel, and a heat exchanger. And the water outlet, the water inlet end and the water outlet end pass through the water-saving funnel upwards, so that the heat exchanger is relatively fixed in the cooling fresh water inside the cooling water tank; the water inlet of the heat exchanger is connected to the seawater inlet pipe, and its water outlet is connected to the seawater outlet pipe.

[0016] When the diesel engine is working, the structure and principle that the diesel engine uses the fresh water in the cooling water tank to cool the diesel engine remain unchanged. The cooling fresh water temperature will increase with time. In this embodiment, the seawater at normal temperature is driven by the propeller blades outside the hull, enters the heat exchanger through the seawater inlet pipe, exchanges heat with t...

Embodiment 2

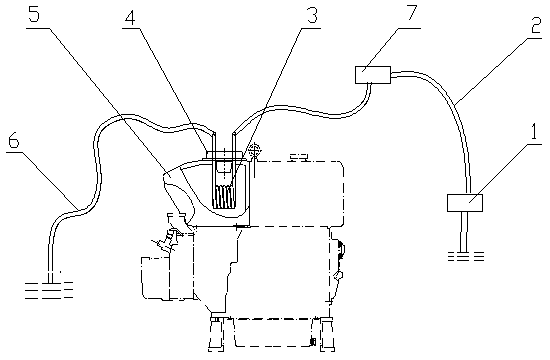

[0017] Embodiment 2: as figure 2 As shown, a marine diesel engine cooling system is applied to ships operating at sea. Its structure and working method are basically the same as those in Example 1, the difference is that a seawater storage system is connected between the heat exchanger water inlet and the seawater inlet pipe. Container, the seawater water storage container is arranged on the position higher than the diesel engine water tank on board. When the diesel engine is working, the propeller blades of the marine engine are used to drive the seawater at normal temperature to enter the heat exchanger through the seawater inlet pipe and the seawater storage container.

Embodiment 3

[0018] Embodiment 3: as Figure 1-2 As shown, a marine diesel engine cooling system is applied to ships operating at sea. Its structure and working method are basically the same as those in Embodiment 1, except that the heat exchanger is made of copper tubes. Its implementation effect is basically consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com