Bionic-attachment-type wearable health monitoring sensor manufacturing method

A technology of health monitoring and manufacturing method, which is applied in the direction of using electric/magnetic devices to transmit sensing components, can solve problems such as sensor fitting and sensor falling off, and achieve the effect of simple manufacturing process, reducing signal-to-noise ratio and ensuring fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] A method for manufacturing a bionic adhesive wearable health monitoring sensor, comprising the following steps:

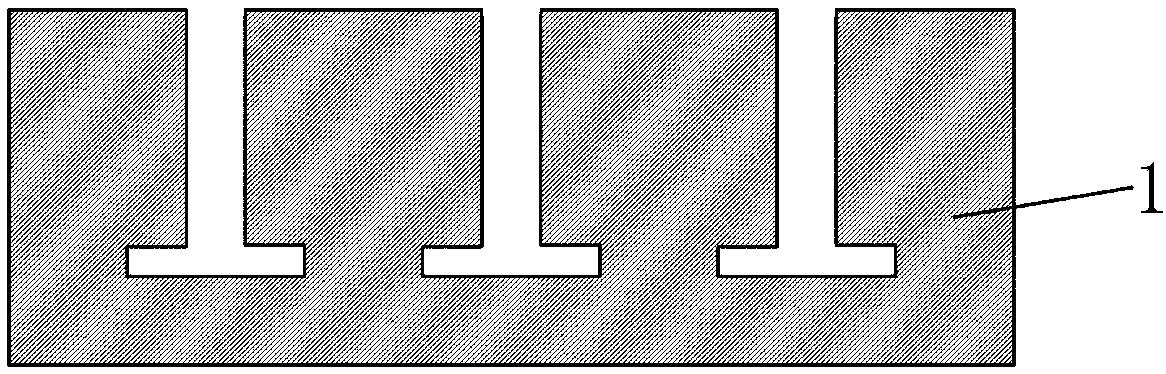

[0022] The first step, the preparation and processing of the membrane mold: use 3D printing technology to prepare a hole mold 1 for the negative replica of the mushroom microarray, such as figure 1 As shown, and surface treatment is carried out to facilitate the demoulding after subsequent film flipping;

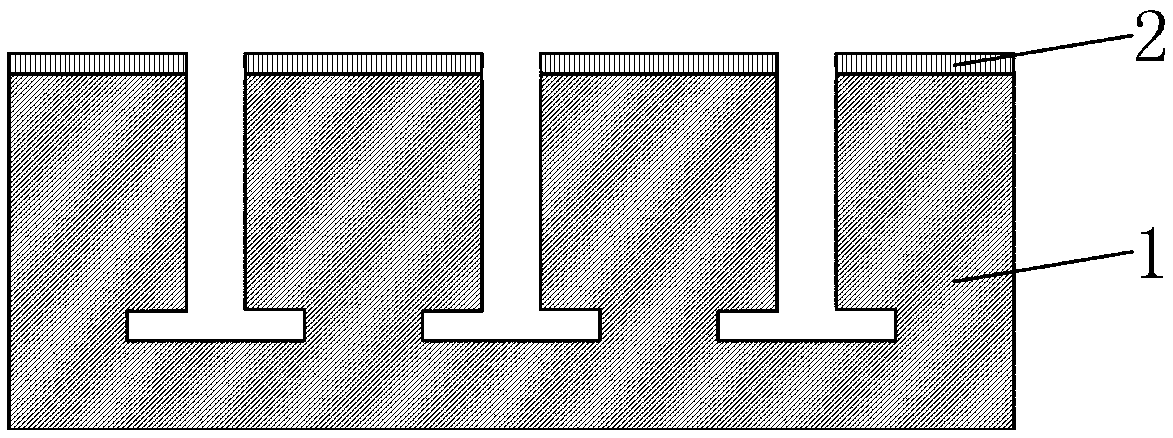

[0023] The second step is to prepare silver nanowire flexible bottom electrode by spraying: spraying on the surface of hole mold 1 to prepare a layer of silver nanowire flexible bottom electrode 2, such as figure 2 shown;

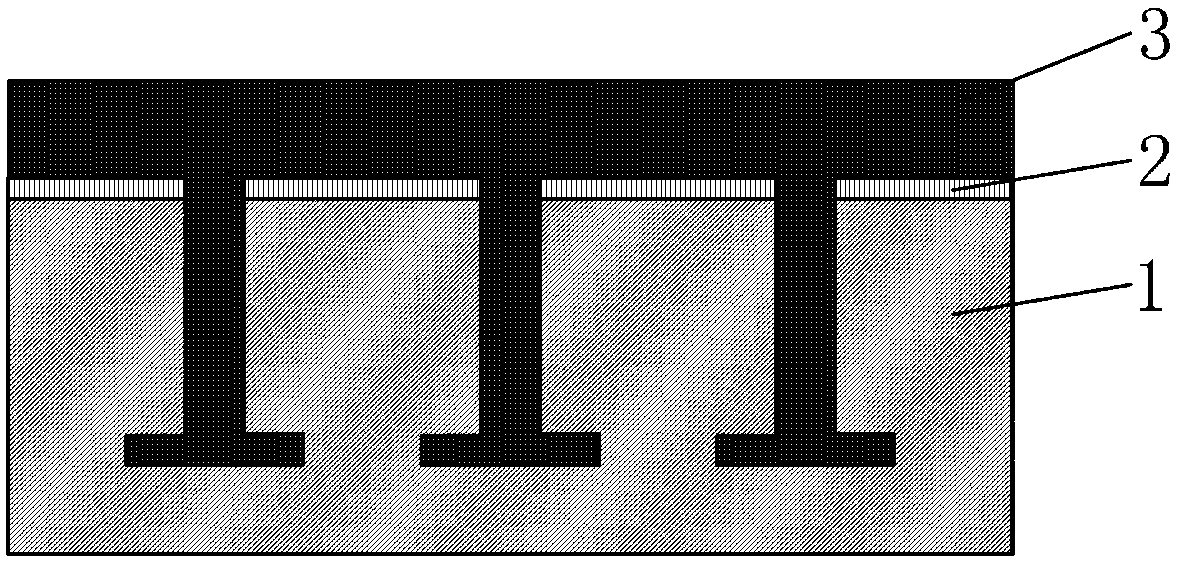

[0024] The third step is to mold the piezoelectric composite material into shape: pour the configured piezoelectric composite material 3 onto the hole mold 1 sprayed with the flexible bottom electrode 2 of silver nanowires,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com