Intelligent stereoscopic cultivation system

A technology of three-dimensional cultivation and analysis system, which is applied in the field of intelligent three-dimensional cultivation system, can solve problems such as uncoordinated control, achieve uniform illumination, improve planting quality, and optimize planting control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

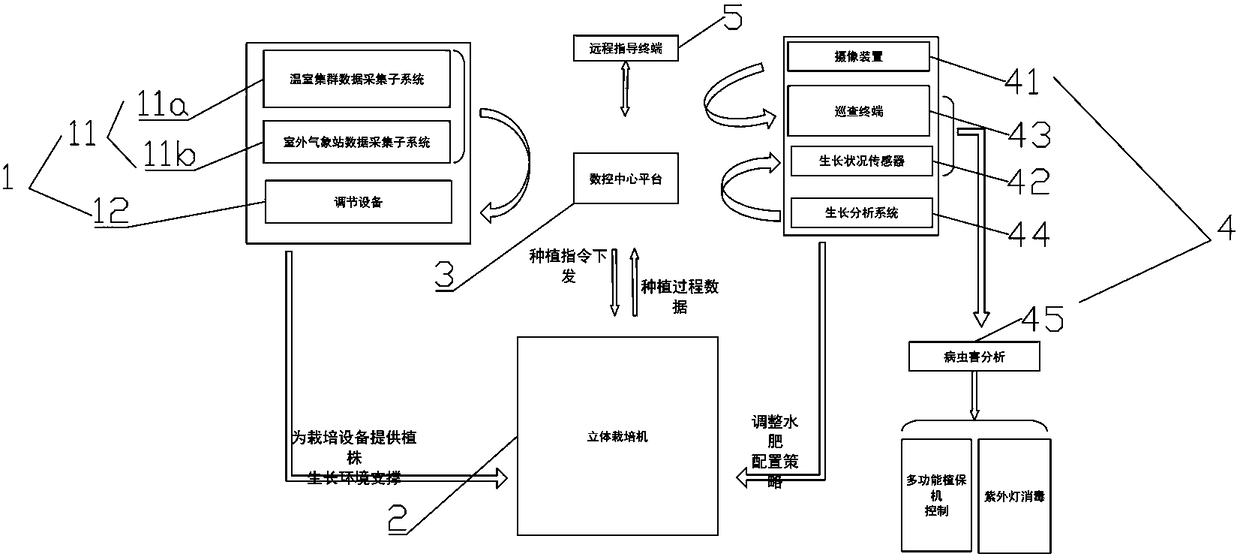

[0063] Such as Figure 1-2 As shown, an intelligent three-dimensional cultivation system includes: an intelligent greenhouse 1, a three-dimensional cultivation machine 2 arranged in the intelligent greenhouse 1 for cultivation and planting, and used in conjunction with the intelligent greenhouse 1 to control the three-dimensional Cultivator 2 carries out the numerical control center platform 3 of adjustment control.

[0064] The numerical control center platform 3 and the three-dimensional cultivation machine 2 communicate with each other and exchange data in real time. The numerical control center platform 3 issues planting instructions to the three-dimensional cultivation machine 2, and the three-dimensional cultivation machine 2 uploads planting instructions in real time. Process data to the CNC center platform 3. The three-dimensional cultivation machine 2 combines the planting environment data in the intelligent greenhouse 1 and the self-operation data of the three-dimen...

Embodiment 2

[0068] For the sake of brevity, the similarities between this embodiment and embodiment 1 will not be repeated here. Only the differences between this embodiment and Embodiment 1 will be described.

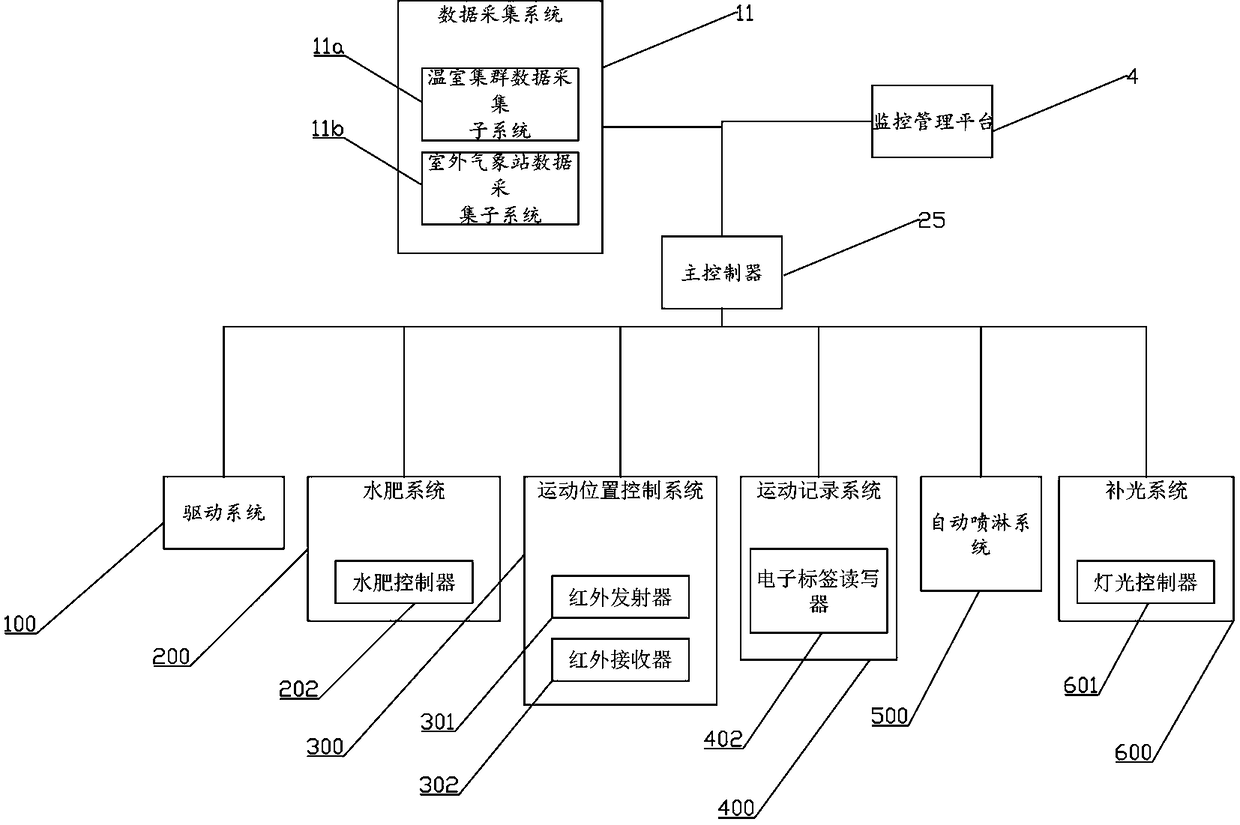

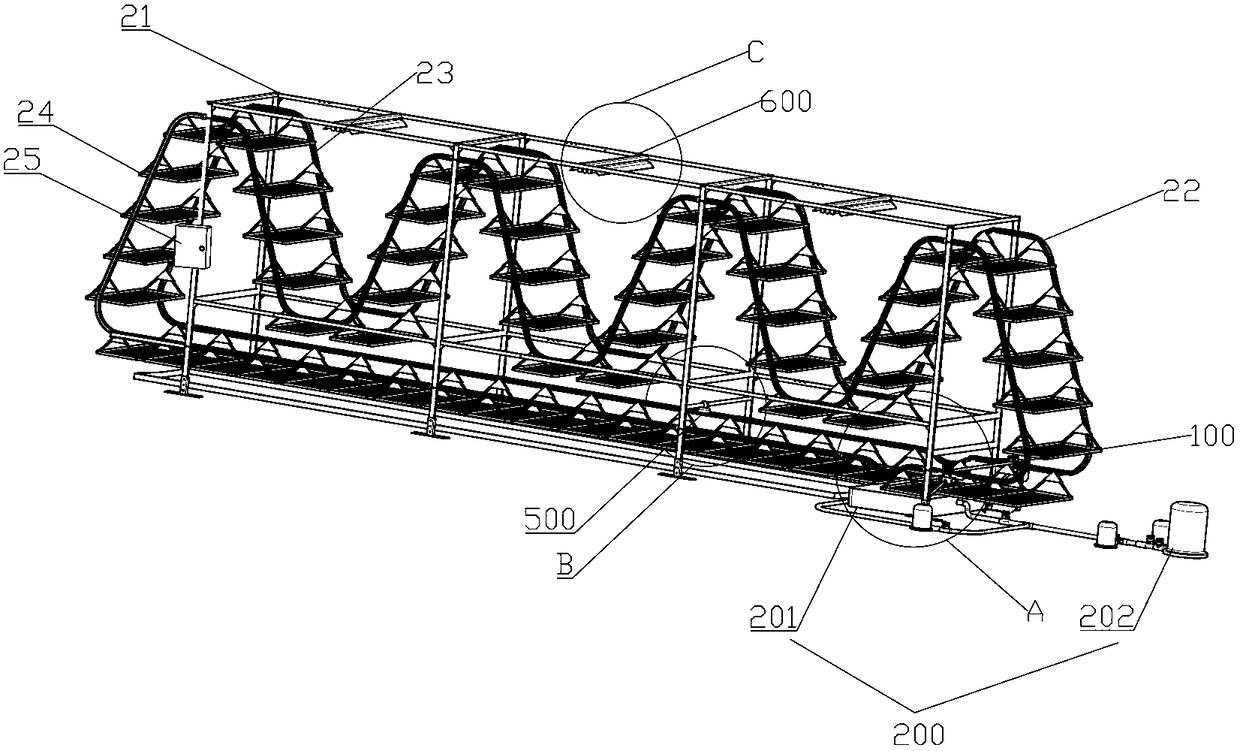

[0069] Such as figure 2 , image 3 and Figure 8 As shown, the three-dimensional cultivation machine 2 of the present embodiment includes a main support bracket 21, a track 22 arranged on the main support bracket 21, a conveyor chain 23 arranged in the track 22, and drives the conveyor chain 23 along the The driving system 100 for the movement of the track 22 and the main controller 25 arranged on the main support bracket 21 for controlling the operation of the intelligent three-dimensional cultivation machine. The frequency converter in the driving system 100 receives the command from the main controller 25 and controls the operation of the three-phase motor. The operation of the three-phase motor provides power for the conveying chain 23 so that the conveying chain 23 can mo...

Embodiment 3

[0072] For the sake of brevity, this embodiment is the same as embodiment 2 and will not be repeated here. Only the differences between this embodiment and Embodiment 2 will be described.

[0073] Such as figure 2 , image 3 , Figure 4 and Figure 8 As shown, the three-dimensional cultivation machine 2 of this embodiment also includes a water and fertilizer system 200 for fertilization, and the water and fertilizer system 200 includes a immersion tank 201 for holding nutrient solution, and the horizontal track includes a When the planting tray 24 moves along the track 22 with the transmission chain 23 and passes through the concave portion 221, the horizontal movement trajectory changes to a downward movement trajectory along the concave portion 221, the The level of the planting tray 24 is gradually lower than the level of the nutrient solution in the immersion tank 201 , the planting tray 24 is immersed in the nutrient solution, and is immersed in the nutrient solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com