Prepackaged cooked-wet scissors-noodles and preparation method thereof

A pre-packaging, scissors technology, applied in food ingredients as taste improver, food science, application and other directions, can solve the problems of scissors surface easy to absorb water, difficult to retain taste, inconvenient to eat, etc., to achieve a wide sales area, promote modernization and market Influence, the effect of preventing corruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

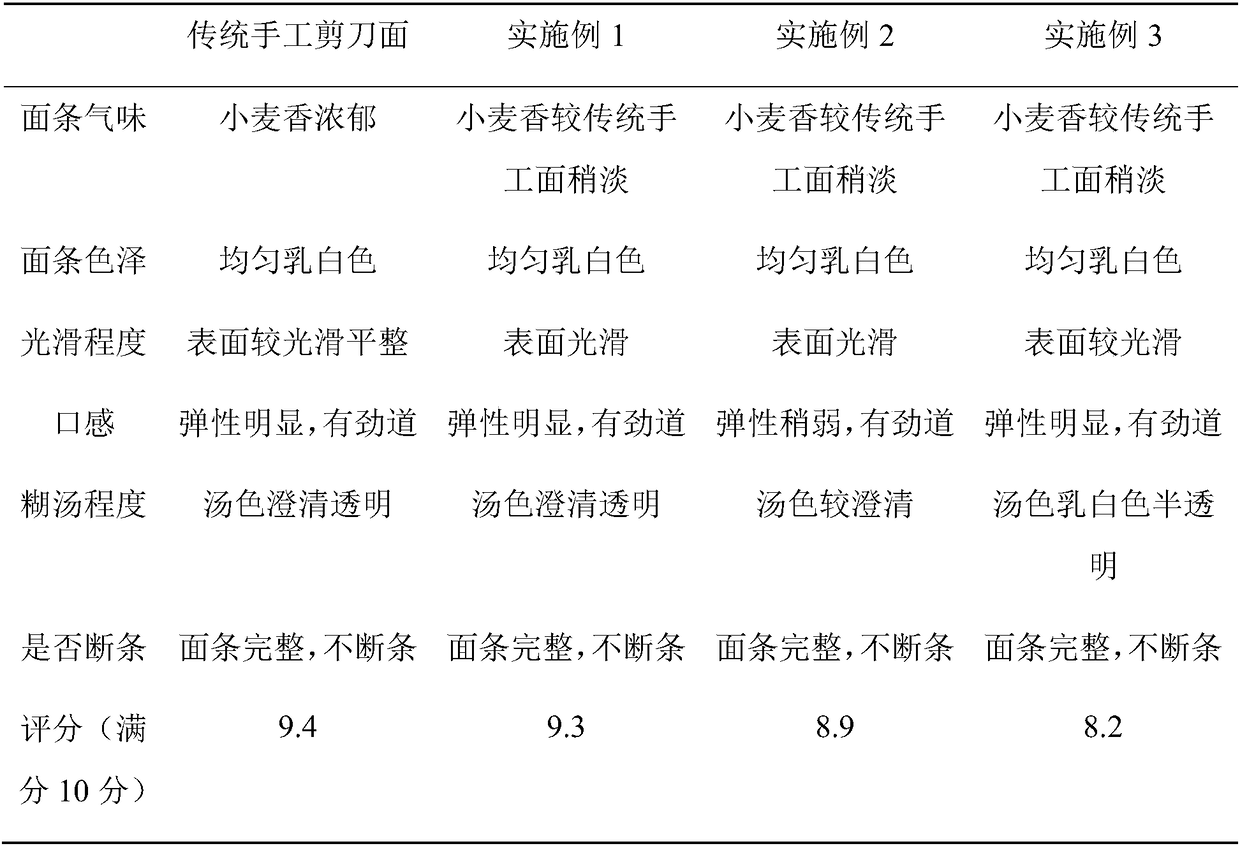

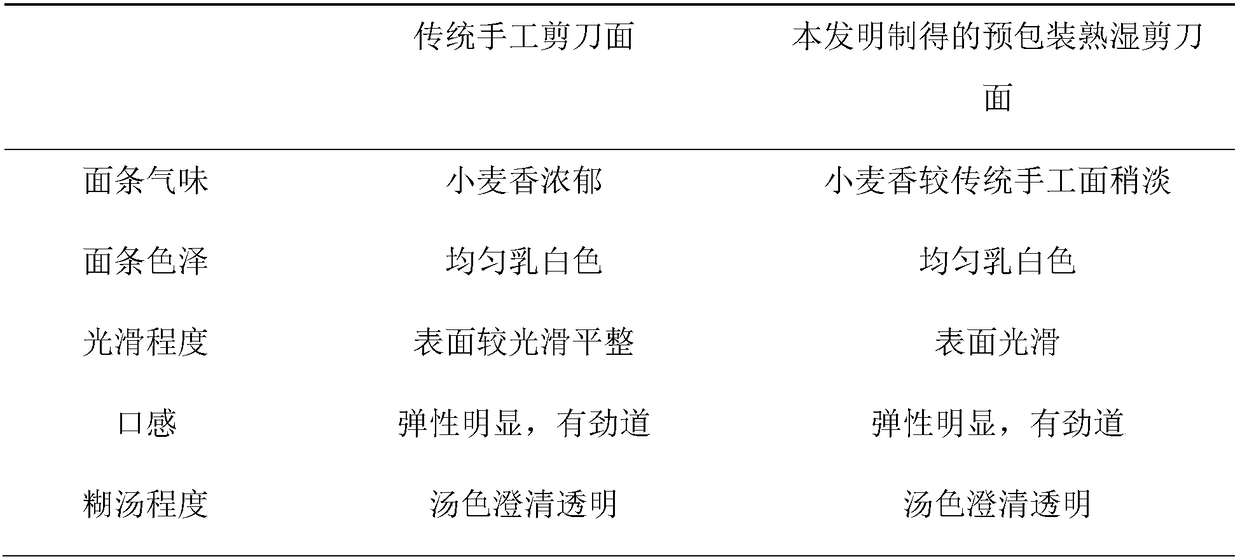

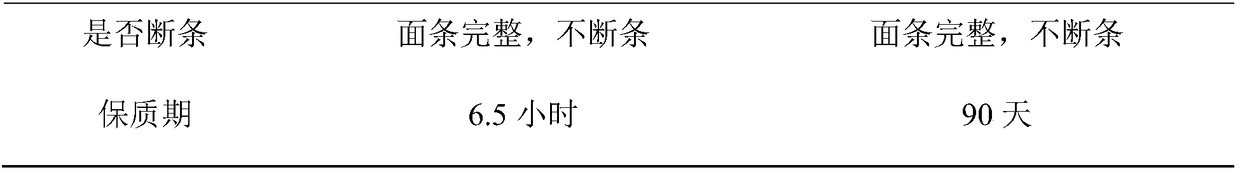

Examples

Embodiment 1

[0041] Prepare a kind of prepackaged cooked wet scissor noodles, the steps are as follows:

[0042] a. Prepare raw materials: by weight, it includes: 100 parts of flour, 36 parts of water, 4 parts of acetate starch, 0.2 part of sodium carboxymethyl cellulose, and 0.2 part of compound phosphate, and stir to obtain flour flocs;

[0043] The compound phosphate is a mixture of sodium tripolyphosphate and sodium hexametaphosphate;

[0044] b. Kneading the dough: knead the flour flocs into a dough, and press it with a noodle press until the surface of the dough sheet is smooth;

[0045] c. Cut strips: Cut the dough piece obtained in step b into small pieces, knead it into a small dough the size of a fist, knead it into an ellipsoid, and then use scissors to cut the dough into a spindle-shaped scissors surface with thick tips at both ends;

[0046] d. Cooking noodles: Put the scissors noodles obtained in step c into boiling water, cook for 2 minutes, and then pick up;

[0047] e. W...

Embodiment 2

[0057] The difference from the examples is that the parts by weight in step a include: 95 parts of flour, 38 parts of water, 2 parts of acetate starch, 0.3 part of sodium carboxymethylcellulose, and 0.5 part of composite phosphate.

Embodiment 3

[0059] Prepare a kind of prepackaged cooked wet scissor noodles, the steps are as follows:

[0060] a. Prepare raw materials: by weight: 110 parts of flour, 36 parts of water, 3 parts of acetate starch, 0.1 part of sodium carboxymethylcellulose, and 0.1 part of compound phosphate. Stir to get flour flocs;

[0061] b. Cutting scissors noodles: use the machine to knead the dough, and the machine cuts the dough into spindle-shaped scissors noodles with thick tips at both ends;

[0062] c. Cooking noodles: Put the scissors noodles obtained in step c into boiling water, cook for 2 minutes, and remove;

[0063] d. Water washing: put the scissors surface obtained in step d into clear water with a temperature of 15°C, rinse for 40 seconds, and drain;

[0064] e. acid leaching: put the scissors noodles obtained in step e into a lactic acid solution with a pH of 2.9, stir and soak for 60 seconds, and drain;

[0065] f. Air-dry the surface: spread out the scissors surface obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com