A kind of cotton-wool blended fabric and clothes made from it

A technology of blended fabrics and cotton wool, which is applied in the field of cotton wool blended fabrics and garments made from them, can solve the problems of inter-fiber cohesion and fiber strength, and improve spinnability, strength, surface friction coefficient and The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

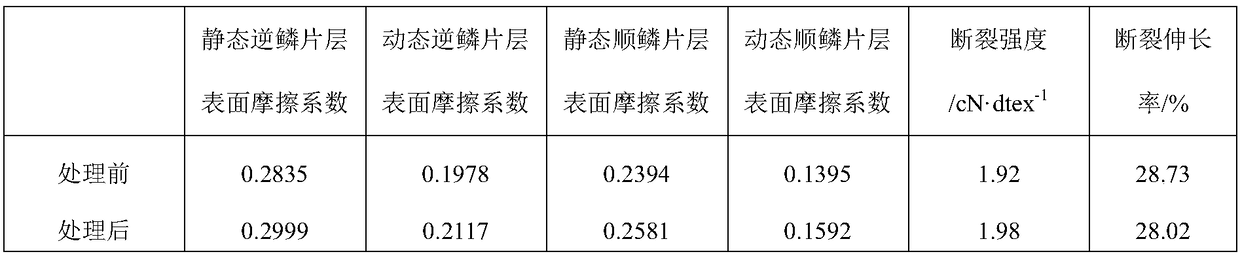

Embodiment 1

[0042] This embodiment provides a cotton-wool blended fabric, which is formed by interweaving warp yarns and weft yarns. The warp density of the fabric is 90 threads / cm, and the weft density is 100 threads / cm, wherein:

[0043] Warp yarn is cotton yarn, accounts for 40wt% of described fabric weight;

[0044] Described weft yarn is cotton-wool blended yarn, and it is prepared by following process:

[0045] S1. Put the wool fiber in distilled water at 50°C, use 195W ultrasonic wave to sonicate the wool fiber, take it out after 15 minutes and drain it, then place the wool fiber after ultrasonic treatment in the soaking solution at 45°C, under -0.03MPa Vacuum impregnation for 0.75h, repeat the above steps 3 times;

[0046] S2, microwave drying the wool fiber obtained in step S1 at 750MHz for 7min;

[0047] S3. Put the cotton fiber in 75°C distilled water, use 210W ultrasonic wave to sonicate the cotton fiber, take it out and drain it after 15 minutes, then place the cotton fiber...

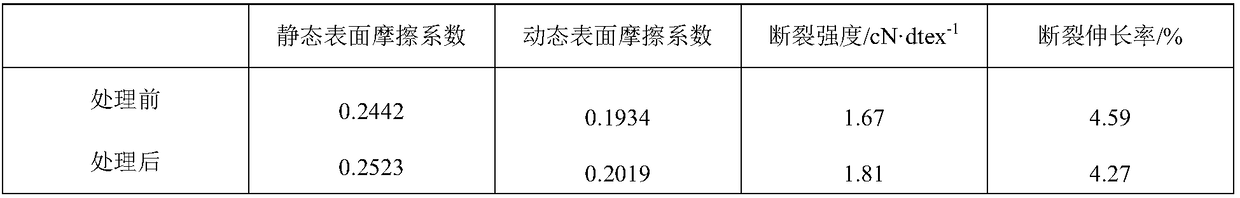

Embodiment 2

[0062] This embodiment provides a cotton-wool blended fabric, which is formed by interweaving warp yarns and weft yarns. The warp density of the fabric is 100 threads / cm, and the weft density is 100 threads / cm, wherein:

[0063] Warp yarn is cotton yarn, accounts for 35wt% of described fabric weight;

[0064] Described weft yarn is cotton-wool blended yarn, and it is prepared by following process:

[0065] S1. Put the wool fiber in 60°C distilled water, use 180W ultrasonic wave to sonicate the wool fiber, take it out after 15 minutes and drain it, then put the wool fiber after ultrasonic treatment in the immersion solution at 55°C, at -0.04MPa Vacuum impregnation for 0.5h, repeat the above steps twice;

[0066] S2. Microwave drying the wool fiber obtained in step S1 at 800 MHz for 10 min;

[0067] S3. Put the cotton fiber in 60°C distilled water, use 220W ultrasonic wave to sonicate the cotton fiber, take it out after 20 minutes and drain it, then place the cotton fiber afte...

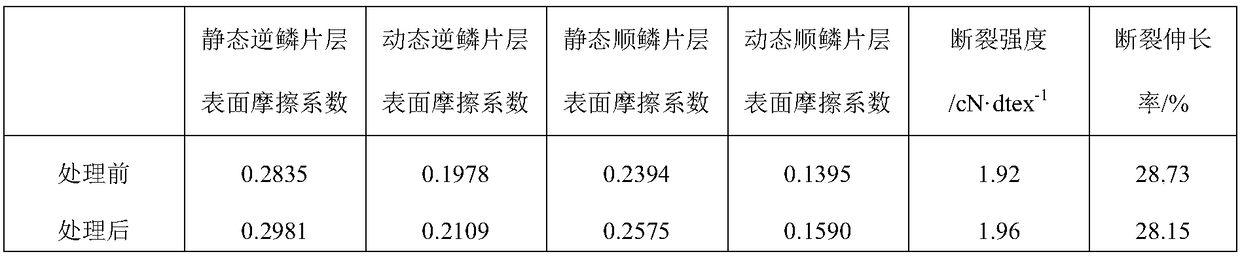

Embodiment 3

[0082] This embodiment provides a cotton-wool blended fabric, which is formed by interweaving warp yarns and weft yarns. The warp density of the fabric is 80 threads / cm, and the weft density is 110 threads / cm, wherein:

[0083] Warp yarn is cotton yarn, accounts for 45wt% of described fabric weight;

[0084] Described weft yarn is cotton-wool blended yarn, and it is prepared by following process:

[0085] S1. Put the wool fiber in 70°C distilled water, use 200W ultrasonic wave to sonicate the wool fiber, take it out after 10 minutes and drain it, then place the wool fiber after ultrasonic treatment in the soaking solution at 40°C, at -0.045MPa Vacuum impregnation for 1h, repeat the above steps 2 times;

[0086] S2. Microwave drying the wool fiber obtained in step S1 at 900 MHz for 4 min;

[0087] S3. Put the cotton fiber in 85°C distilled water, use 200W ultrasonic wave to sonicate the cotton fiber, take it out and drain after 30min, then place the cotton fiber after ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com