Oil-control concealing liquid foundation and preparation method thereof

A liquid foundation and concealer technology, which is applied in the field of oil control and concealer liquid foundation and its preparation, can solve the problems of poor oil control and concealer effect of foundation liquid, ineffective oil control and concealer, greasy, etc., so as to reduce skin brightness, improve concealer effect, Long-lasting makeup effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

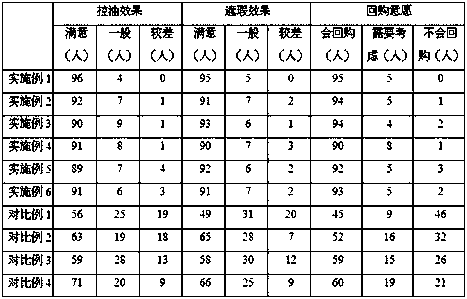

Examples

Embodiment 1

[0029] This example is prepared from the following raw materials by weight: 9 g of tapioca starch, 5.5 g of kaolin, 4 g of aluminum octenyl succinate starch, 7 g of titanium dioxide, 2 g of polymethylsilsesquioxane, 1.5 g of sorbitol, and 2.5 g of polyethylene glycol g, methylparaben 0.3g, phenoxyethanol 0.3g, vitamin E acetate 0.25g, propyl gallate 0.25g, iron oxide red 0.5g, iron oxide yellow 0.7g and distilled water 65g; Starch 3g, cross-linked denatured tapioca starch 6g.

[0030] The particle size of the tapioca starch native starch is 40-50 μm.

[0031] The particle size of titanium dioxide is 0.2~0.5μm.

[0032] Preparation:

[0033] 1) Add tapioca starch, sorbitol, polyethylene glycol and distilled water into the water phase pot at room temperature, slowly raise the temperature to 65°C, and keep stirring, keep it warm for 150 minutes after stirring evenly, and then cool down to 50°C within 30 minutes;

[0034] 2) Keep the temperature at 500°C, add kaolin, aluminum o...

Embodiment 2

[0038] This example is prepared from the following raw materials by weight: 9 g of tapioca starch, 5.5 g of kaolin, 4 g of aluminum octenyl succinate starch, 7 g of titanium dioxide, 2 g of polymethylsilsesquioxane, 1.5 g of sorbitol, and 2.5 g of polyethylene glycol g, 0.2g of phenoxyethanol, 0.4g of phenoxyethanol, 0.5g of propyl gallate, 1.2g of iron oxide red and 65g of distilled water; 4.5g of native tapioca starch and 4.5g of crosslinked denatured tapioca starch in tapioca starch.

[0039] The particle size of the tapioca starch raw starch is 60-80 μm.

[0040] The particle size of titanium dioxide is 0.6~0.8μm.

[0041] The preparation method is the same as in Example 1.

[0042] The obtained liquid foundation viscosity is 810rpm.

Embodiment 3

[0044] This example is prepared from the following raw materials by weight: 8 g of tapioca starch, 5.5 g of kaolin, 4 g of aluminum octenyl succinate starch, 7 g of titanium dioxide, 2 g of polymethylsilsesquioxane, 1.5 g of sorbitol, and 2.5 g of polyethylene glycol g, phenoxyethyl ester 0.6g, vitamin E acetate 0.5g, iron oxide black 1.2g and distilled water 65g; Tapioca native starch 2g, cross-linked denatured tapioca starch 6g in tapioca starch.

[0045] The particle size of the tapioca starch raw starch is 30-40 μm.

[0046] The particle size of titanium dioxide is 0.8~1.0μm.

[0047] The preparation method is the same as in Example 1.

[0048] The obtained liquid foundation viscosity is 680rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com