Raw bamboo fiber integrated wire former

A bamboo fiber and silk machine technology, applied in the directions of fiber mechanical separation, fiber processing, mechanical processing, etc., can solve the problems of high production cost and low production efficiency, and achieve the effects of high speed, improved production efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

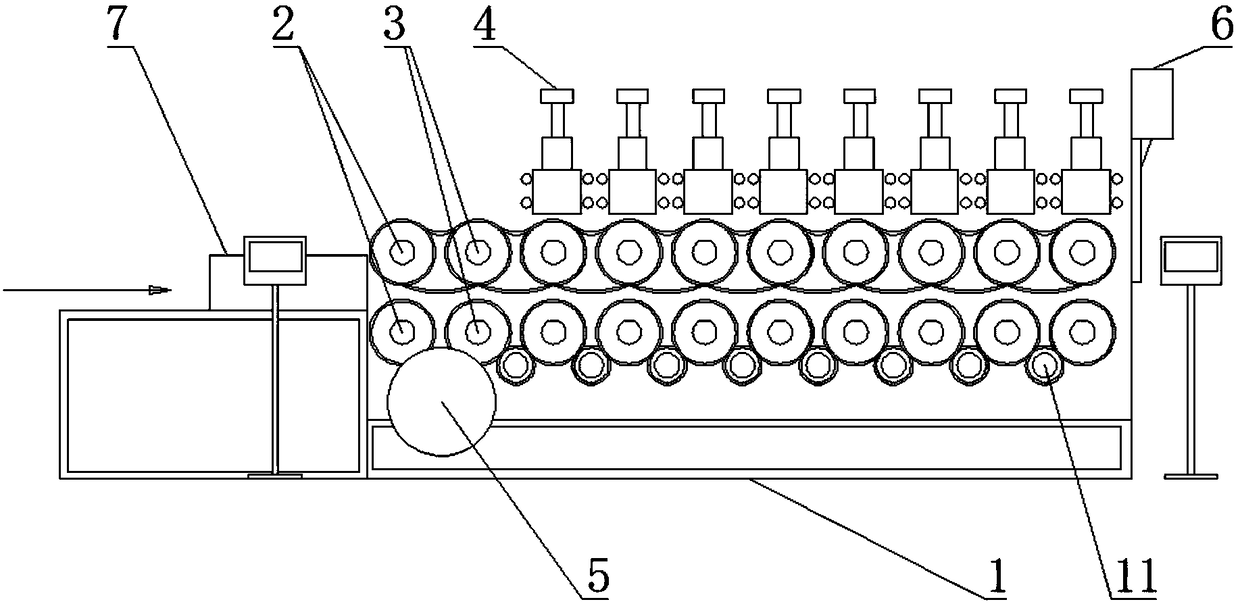

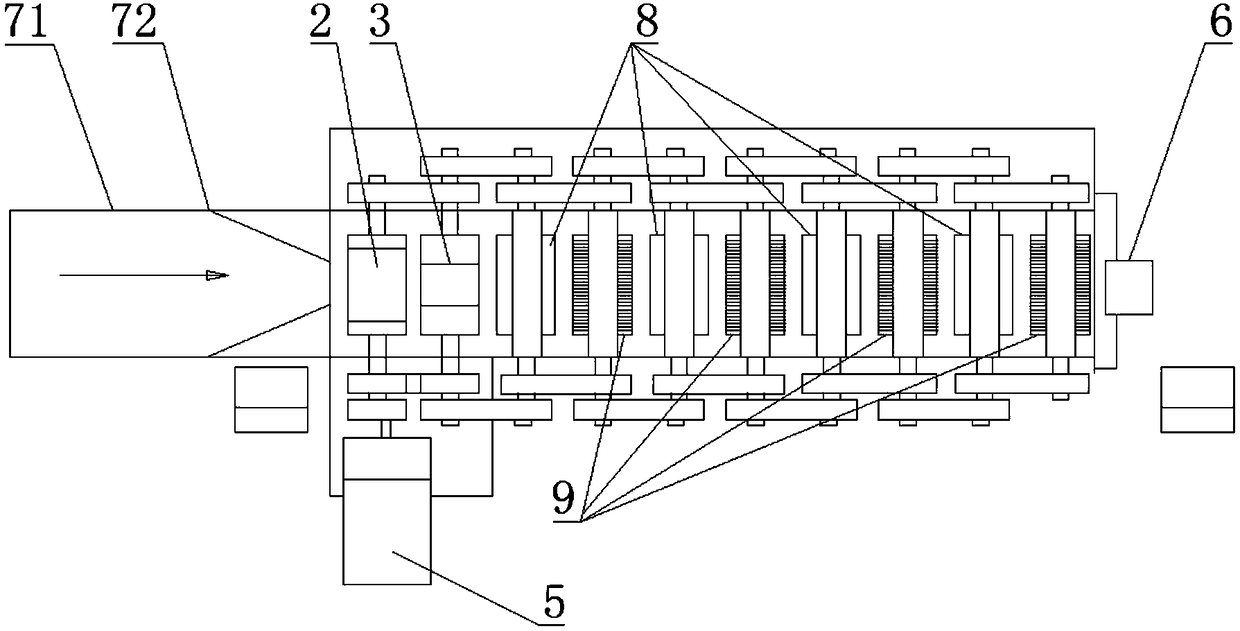

[0055] A kind of primary silk-forming machine for raw bamboo fibers, comprising a frame 1, on which a raw material conveying device 7, a breaking roller assembly 2, and a silk-forming assembly are sequentially arranged from left to right along the raw material conveying direction, and the silk-forming assembly includes several groups Photopress roller assembly 8 and knife roller assembly 9 arranged at intervals.

[0056] In this embodiment, a raw material conveying device 7 , a breaking roller assembly 2 , and a filament forming assembly are sequentially arranged on the frame 1 along the raw material conveying direction from left to right. The raw material conveying device 7 continuously conveys the bamboo tubes into the breaking roller assembly 2, and the breaking roller assembly 2 breaks the bamboo tubes of different diameters, flattens, cuts them into bamboo slices, and the bamboo slices enter the filament forming assembly along the raw material conveying direction , The fi...

Embodiment 2

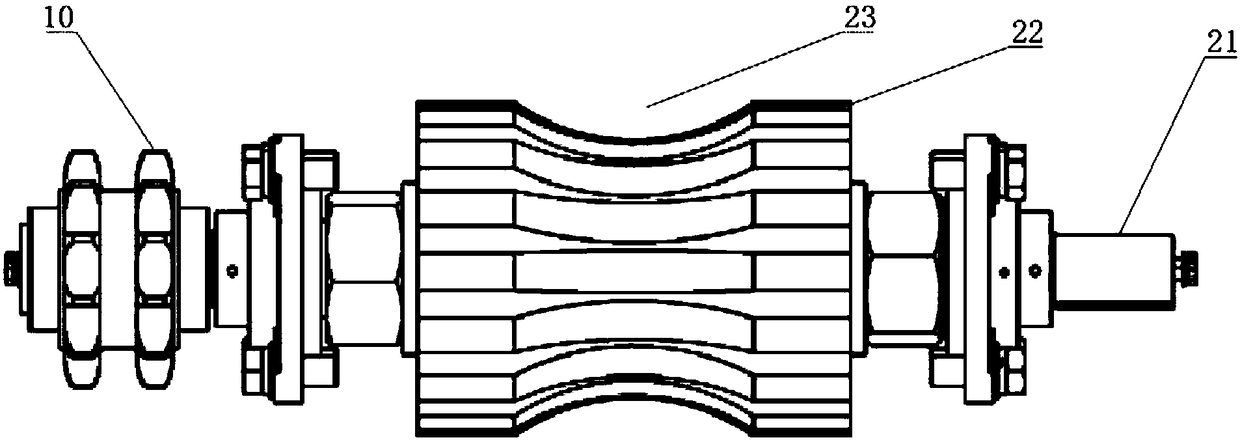

[0058] On the basis of Embodiment 1, the breaking roller assembly 2 includes an upper breaking roller assembly and a lower breaking roller assembly correspondingly arranged up and down; both the upper breaking roller assembly and the lower breaking roller assembly include a breaking The opening roller shaft 21 is sleeved with a feed roller 22 on the opening roller shaft.

[0059] In this embodiment, the breaking roller assembly 2 includes an upper breaking roller assembly and a lower breaking roller assembly correspondingly arranged up and down; both the upper breaking roller assembly and the lower breaking roller assembly include a breaking roller shaft arranged on the frame 21. A feed roller 22 is sheathed on the breaking roller shaft. The feeding rollers 22 of the upper broken roller assembly and the lower broken roller assembly will break, flatten and cut the bamboo tubes of different diameters delivered here, with high efficiency and fast speed.

Embodiment 3

[0061] On the basis of Embodiment 2, the outer wall of the feed roller 22 is evenly distributed with rectangular blades in the circumferential direction, and an annular groove 23 is arranged in the middle of the rectangular blades.

[0062] In this embodiment, the outer wall of the feeding roller 22 is evenly distributed with rectangular blades in the circumferential direction, and the rectangular blades will be cut into the bamboo tubes flattened by the feeding rollers. An annular groove 23 is arranged in the middle of the rectangular blades, and the annular groove 23 will cut the bamboo tube with a larger diameter. The bamboo tube is flattened and cut, which also limits the conveying direction of the bamboo tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com