Design method for horizontal-pushing-type dovetail joint assembly-type frame nodes of square steel tube column and H-shaped beam

A technology of square steel pipe and dovetail tenon, which is applied in the field of joint design of square steel pipe column and I-beam flat-push dovetail tenon assembly frame, can solve the problems of difficult beam-column joint connection technology and difficult replacement or reuse of components, and achieve Reduce the difficulty of bolt installation and accuracy deviation, the effect of simple design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical content and installation process of the present invention, it is introduced in conjunction with the accompanying drawings.

[0026] Step 1. Factory prefabricated frame beams and frame columns, and prefabricated connecting components.

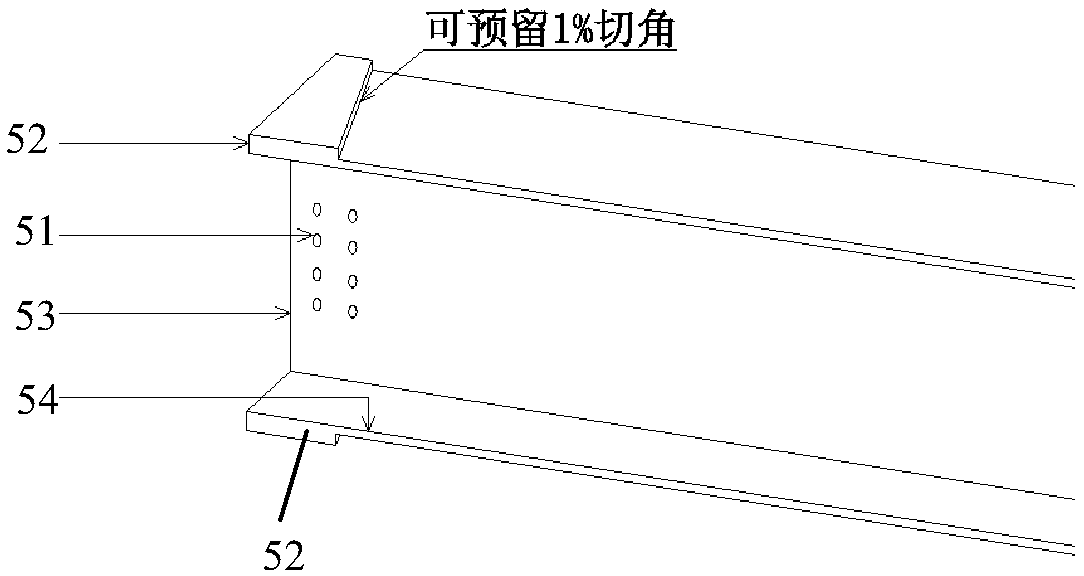

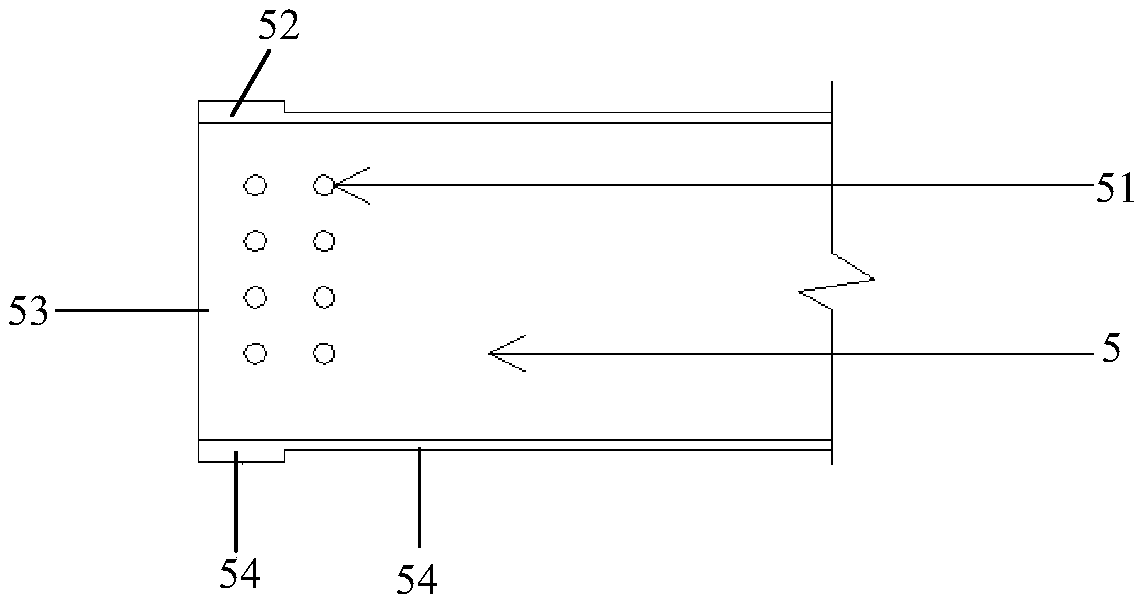

[0027] 1.1. Both the upper and lower flanges of the frame beam end are doubled and thickened by valgus to form a dovetail tenon, which is used to connect and anastomose the column shoulder joint beam mortise, such as figure 1 , 2 shown. There are several reference methods for valgus measures: add an iron plate of equal width and thickness to the position of the normal I-beam beam end; cut off the flange at the position of the tenon at the end of the beam, and weld a dovetail tenon steel plate twice the thickness of the beam flange ; Take the method of binding to process the shape of the dovetail tenon.

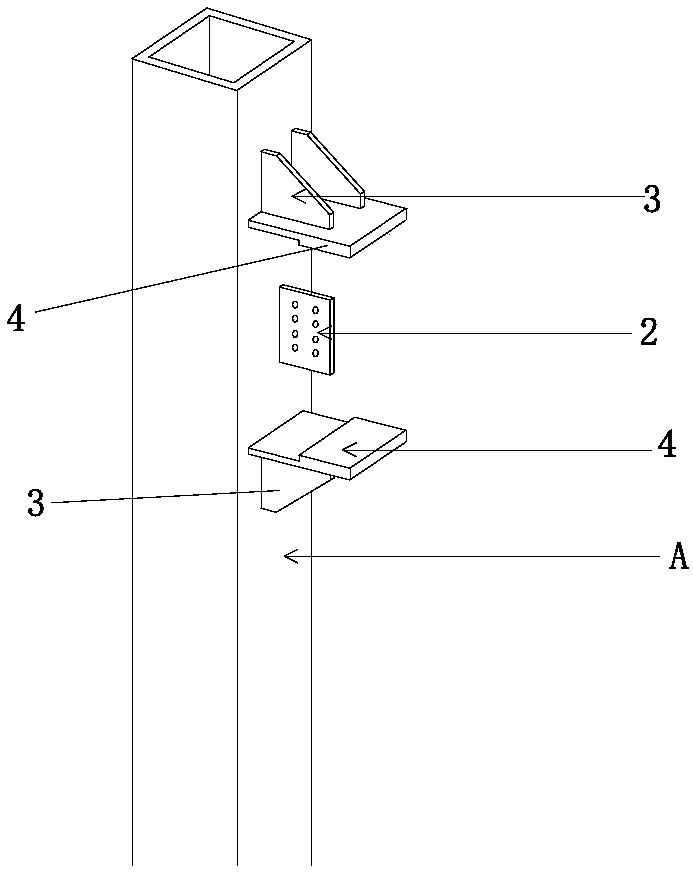

[0028] 1.2. The joint area of the A-end of the square steel pipe column must be prefabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com