Oil well low differential pressure addition sand prevention process method

A process method and sand control technology, which can be used in earth-moving drilling, flushing wellbore, wellbore/well components, etc., and can solve the problems of small packing layer conductivity, large additional pressure difference, and incompact sand control packing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

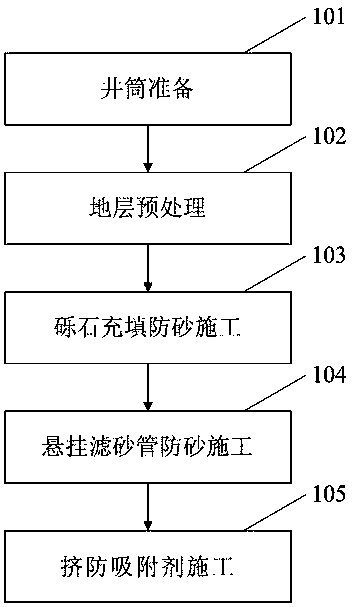

[0031] Such as figure 1 as shown, figure 1 It is a flow chart of the low additional pressure difference sand control process for oil wells of the present invention.

[0032] Step 101. Wellbore Preparation

[0033] (1) Pull out the original well string: pull out the original well production string, salvage the original well sand control pipe, and observe the damage of the original well string and the falling objects at the bottom of the well.

[0034] (2) Sand flushing: lower the light tubing with bell mouth, sand flushing to the bottom of the artificial well, and remove residual sand in the well, with a displacement of 300L / min to 600L / min.

[0035] (3) Well opening and scraping pipe: lower the well opening gauge to the bottom of the artificial well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com