Experimental apparatus for simulating in-vivo dissolution and absorption process of oral drug preparation

A technology of absorption process and pharmaceutical preparations, applied in the direction of testing pharmaceutical preparations, material inspection products, etc., can solve the problems of low sensitivity, weak stirring effect, difficult to overcome drug cohesion, etc., to avoid pipeline leakage and enhance liquid. The effect of flow scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

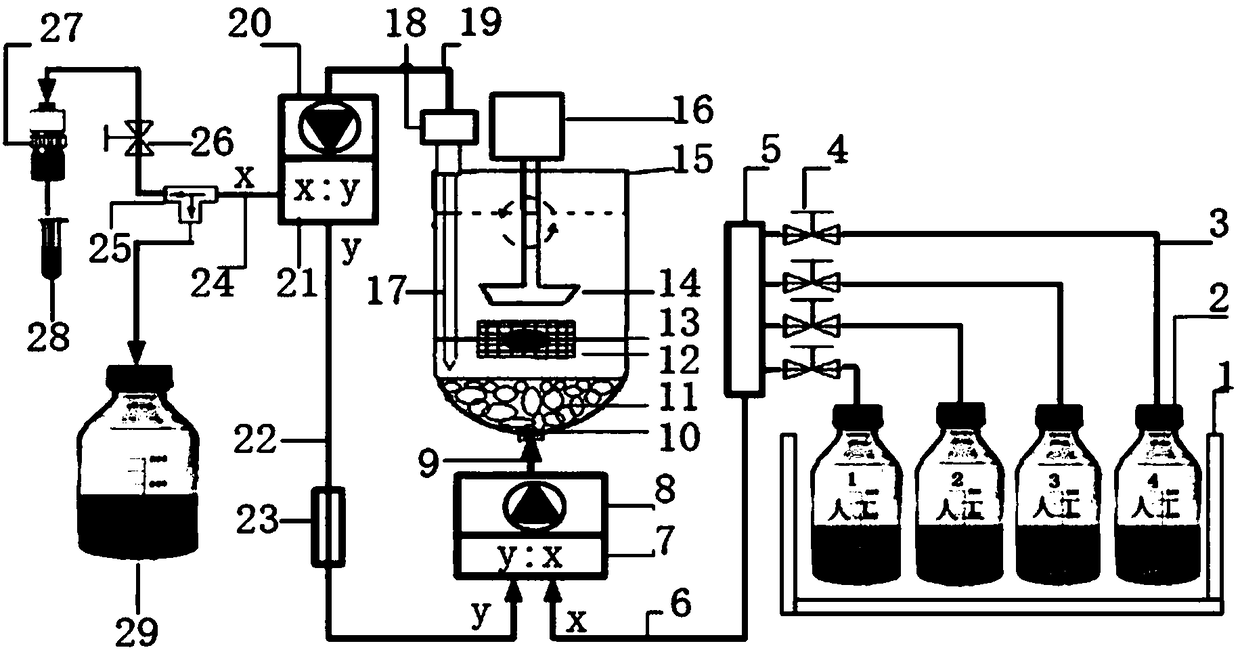

[0028] See figure 1 , An experimental device that simulates the dissolution and absorption process of oral pharmaceutical preparations in vivo, including a dissolution tank 15 with an open top. Specifically, the bottom end of the dissolution tank 15 is tapered with a filter plate inside. The space enclosed by the filter plate and the conical bottom end of the dissolution tank 15 is filled with inert microspheres 11, and the inside of the dissolution tank 15 is located in the filter. A drug basket 12 containing drugs 13 (oral drug preparations) is suspended above the plate, and a liquid inlet 10 is provided at the lowest position of the conical bottom end of the dissolution tank 15. The liquid inlet 10 passes through the main liquid inlet 9 and The outlet of the merging valve 7 is connected, and the liquid outlet connector 17 inserted from the top of the dissolution tank 15 transports the dissolution medium in the dissolution tank 15 to the diverter valve 21 through the effluent...

Embodiment 2

[0033] The difference from Embodiment 1 is that the medium input pipeline 6 in this embodiment is divided into a plurality of medium conveying branches 3 connected to the medium storage bottle 2 through the medium selector 5, and each medium conveying branch 3 is provided There is an inlet control valve 4, and each medium storage bottle 2 is equipped with different bionic dissolution media. In addition, in this embodiment, the content of the dissolution medium in the dissolution tank 15 is 5-60 ml.

[0034] In this embodiment, a micro stirrer is also provided above the drug basket 12 in the dissolution tank 15, and an openable and closable top cover is provided on the top open end of the dissolution tank 15. Specifically, in this embodiment, the micro-agitator includes a stirring paddle 14 and a high-precision stirring pump 16. One end of the stirring paddle 14 is connected to the high-precision stirring pump 16 after passing through the top cover. By adjusting the rotation spee...

Embodiment 3

[0037] The difference from Example 2 is that the experimental device for simulating the dissolution and absorption process of oral pharmaceutical preparations in this example also includes a water bath 1, and each medium storage bottle 2 is preheated and insulated through the water bath 1, so that each dissolution medium It is close to the biological temperature (37°C). Preferably, a sample collection control valve 26 is provided on the pipeline between the sample collection three-way valve 25 and the sample collector 27. An in-line filter 18 is provided at the connection between the liquid outlet connector 17 and the liquid outlet main line 19; a fine filtration membrane structure with better filtering effect (smaller pore size) is provided on the sample collector 27. Preferably, an insulation jacket 23 is provided around part of the pipeline of the circulation loop 22, and the insulation jacket 23 is heated by a high-precision heater to keep the flowing medium in the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com