Distillation device and method for solid-containing raw oil

A distillation device and raw oil technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures. It can solve the problems of easy wear or blockage of equipment and pipelines, operation cycle of less than one month, and high solid content, so as to reduce wear and flow. Reasonable, the effect of improving the degree of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

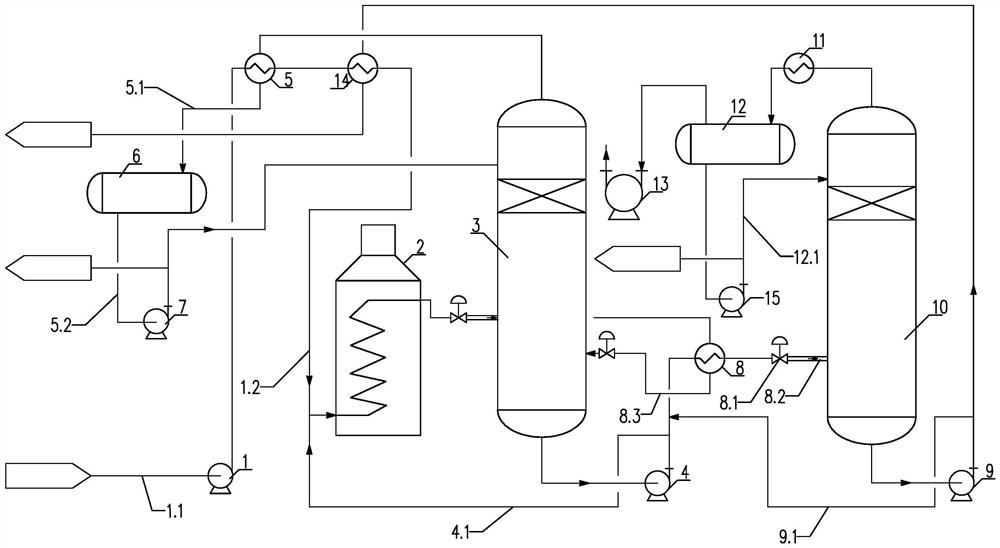

[0039] as attached figure 1 As shown, the distillation device of the solid-containing raw material oil of the present embodiment includes an atmospheric heating furnace 2 and an atmospheric tower 3. The atmospheric heating furnace and the atmospheric tower are connected by pipelines, and the interconnected The pipeline is provided with a first pressure-suppressing regulating valve 2.1 and a first expansion pipe 2.2; the upper end of the atmospheric tower is provided with a gas-phase circulation pipeline 2.3, and the other end of the gas-phase circulation pipeline is connected to the top heat exchanger 5 of the atmospheric pressure tower , said atmospheric pressure tower top heat exchanger 5 is also connected with raw material inlet pipeline 1.1 and raw material output pipeline 1.2, raw material inlet pipeline is provided with raw material pump 1, and the other end of said raw material output pipeline is connected with normal pressure heating furnace 2 are connected, the bottom...

Embodiment 2

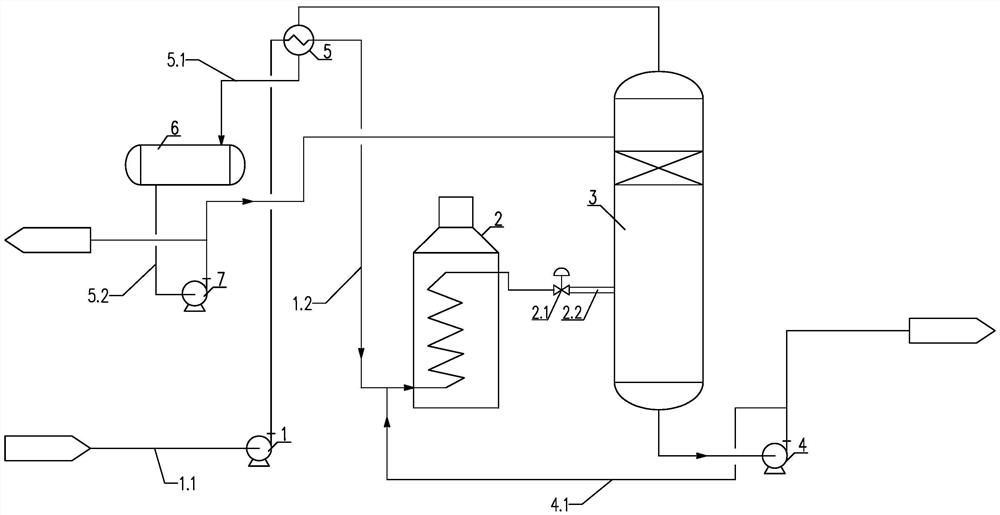

[0047] as attached figure 2 As shown, the distillation device of the solid-containing raw material oil of the present embodiment includes an atmospheric heating furnace 2 and an atmospheric tower 3. The atmospheric heating furnace and the atmospheric tower are connected by pipelines, and the interconnected The pipeline is provided with a first pressure-suppressing regulating valve 2.1 and a first expansion pipe 2.2; the upper end of the atmospheric tower is provided with a gas-phase circulation pipeline 2.3, and the other end of the gas-phase circulation pipeline is connected to the top heat exchanger 5 of the atmospheric pressure tower , said atmospheric pressure tower top heat exchanger 5 is also connected with raw material inlet pipeline 1.1 and raw material output pipeline 1.2, raw material inlet pipeline is provided with raw material pump 1, and the other end of said raw material output pipeline is connected with normal pressure heating furnace 2 connected, the bottom of...

Embodiment 3

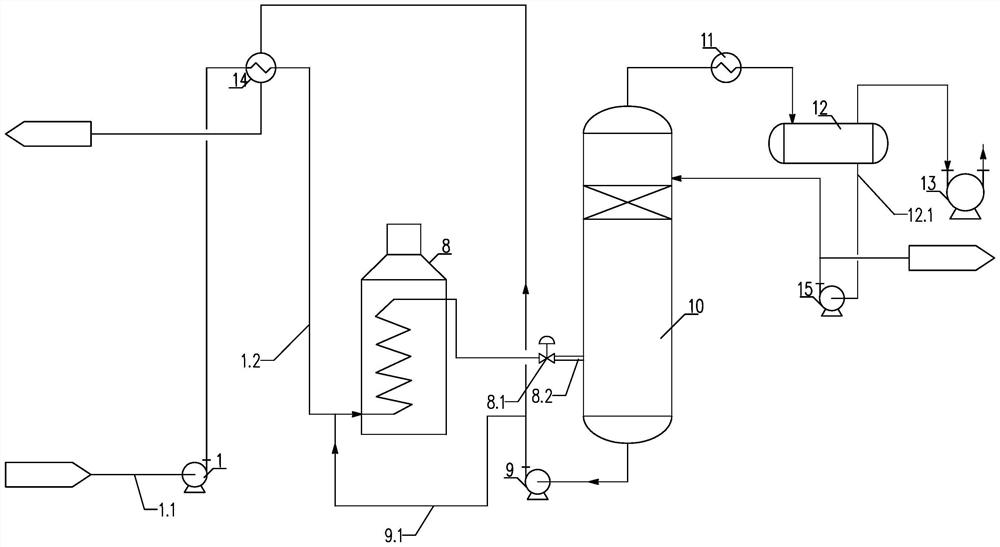

[0054] as attached image 3As shown, the distillation device of the solid-containing raw oil of the present embodiment comprises that the device comprises a vacuum tower feed heat exchanger or a vacuum furnace (decompression heating furnace) 8, a vacuum tower 10, and the described vacuum tower The feed heat exchanger of the pressure tower or the decompression furnace (decompression heating furnace) 8 and the decompression tower 10 are connected by pipelines, and a second pressure-holding regulating valve 8.1 and a second expansion pipe are arranged on the interconnected pipelines. 8.2; the upper end of the described decompression tower 10 is connected with the second tower top tank 12 by pipeline, and the pipeline connected is provided with a decompression tower top condenser 11, and the third tower top tank 12 is provided with a third Pipeline 12.1, the other end of described the 3rd pipeline is connected with decompression tower (realize that the component part recirculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com