Straw crusher with composite cutter roller

A technology of straw shredder and compound knife, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of easily causing forest fires, affecting air quality, and difficult to operate small machinery, and achieving a compact and stable overall structure, The effect of reducing the overall weight and increasing the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

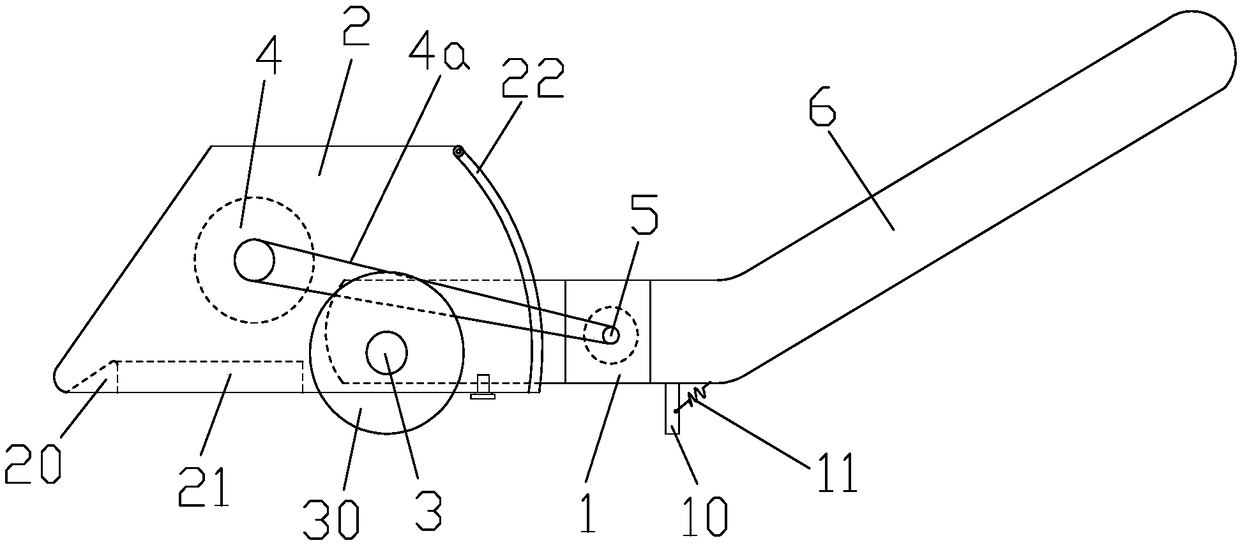

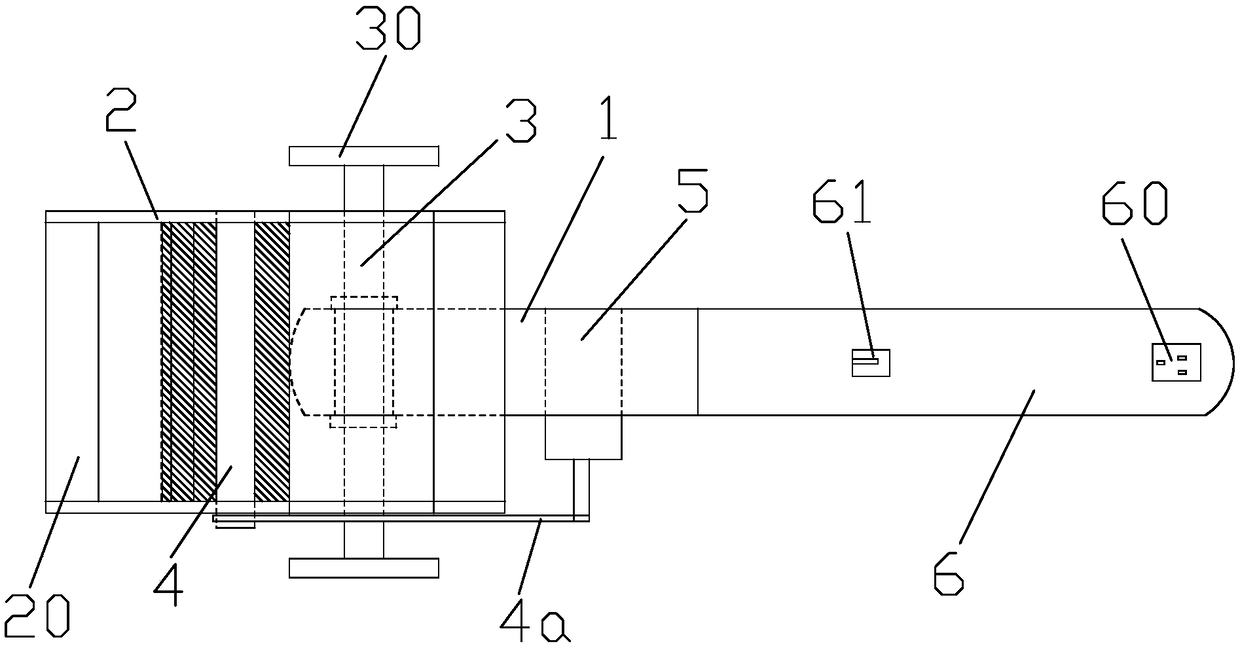

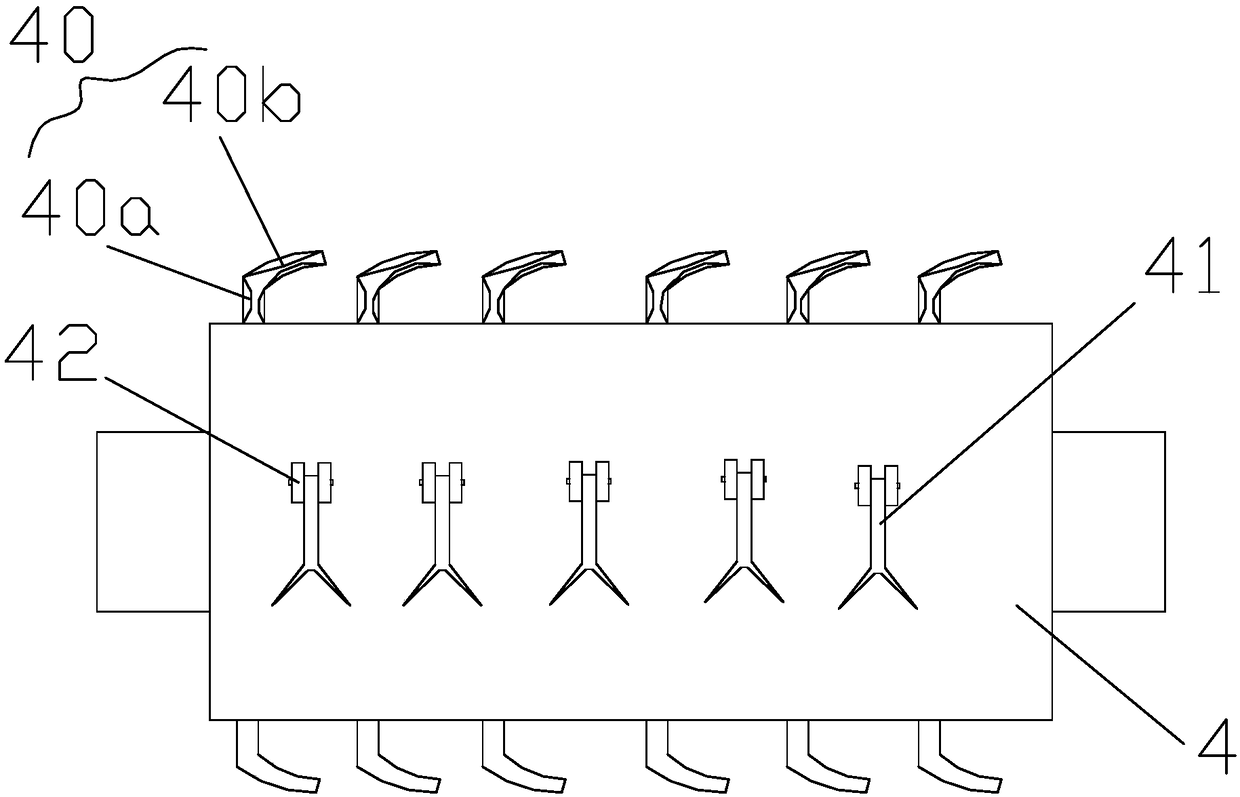

[0022] refer to Figure 1 to Figure 3 , the straw pulverizer with composite knife roller of the present invention mainly includes a frame 1 and a suspension cover 2 arranged horizontally. In the present invention, the frame 1 is a hollow cuboid columnar structure, and the front end is pierced with a wheel shaft 3, and the wheel shaft 3 is horizontal. It is arranged and perpendicular to the axial direction of the frame 1, and the wheel shaft 3 can be fixedly installed on the frame 3 without rotation.

[0023] The suspension cover 2 is detachably supported on the frame 1. In the present invention, the suspension cover 2 is surrounded by a left side plate, a right side plate, a top plate and a bottom plate, and the top plate is relatively short relative to the bottom plate, so the encirclement forms a trapezoidal cross section. Tubular structure, its front and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com