Fat additive and fried oil composition

A technology of oil composition and additives, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of poor working experience of employees and affect the health of employees, achieve flavor improvement, improve frying operation environment, improve Effects of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Grease composition A: get 9500g high oleic sunflower oil, 500g refined rice oil respectively, control the content of unsaturated fatty acid and styrene to be: C18:2+C18:3=10% weight, and (C18:2+C18 :3) / styrene=1.0*10 6 , 1000ppmVE is added to the batching tank, maintain the temperature at 20°C-40°C, and stir at a speed of 50r / min for 20-30 minutes, filter and fill;

[0082] Grease composition B: take 9500g high oleic sunflower oil, 500g deacidified rice oil, and 1000ppm VE into the batching tank, keep the temperature at 20°C-40°C, and stir at a speed of 50r / min for 20-30 minutes , obtained by filtering and filling, after testing: C18:2+C18:3=10% by weight, (C18:2+C18:3) / styrene=8.3*10 4 ;

[0083] Grease composition C: Take 9500g of high oleic sunflower oil, 500g of high-temperature deodorized refined rice oil, and 1000ppm VE into the batching tank, keep the temperature at 20°C-40°C, and stir at a speed of 50r / min for 20-30 Minutes, it can be obtained by filtering an...

Embodiment 2

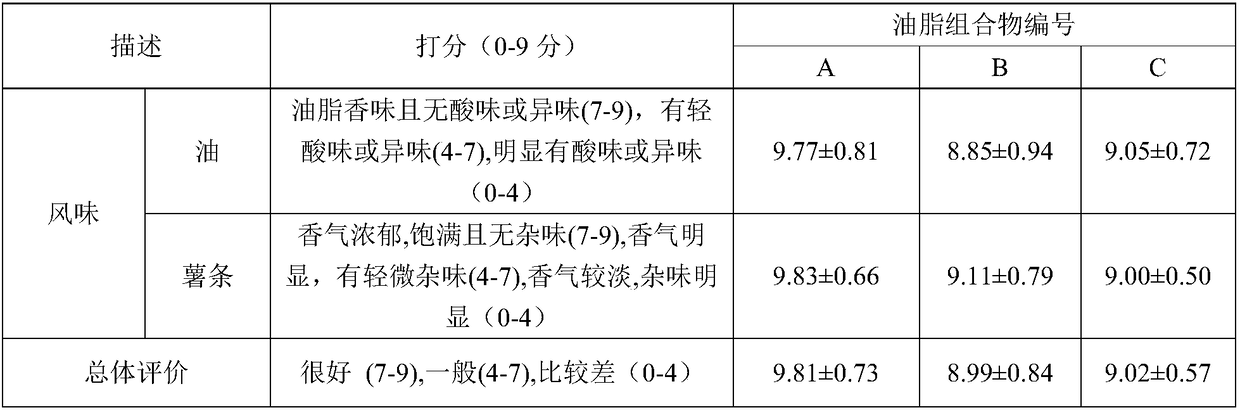

[0085] The oil and fat composition A / B / C obtained in Example 1 were respectively subjected to frying French fries experiment at 180±5°C, the frying time was 3 minutes per pot, and then the oil was drained for 3 minutes, and after every 10 pots, it was empty-fired for 2 hours. Lasts 40 pots in total.

Embodiment 3

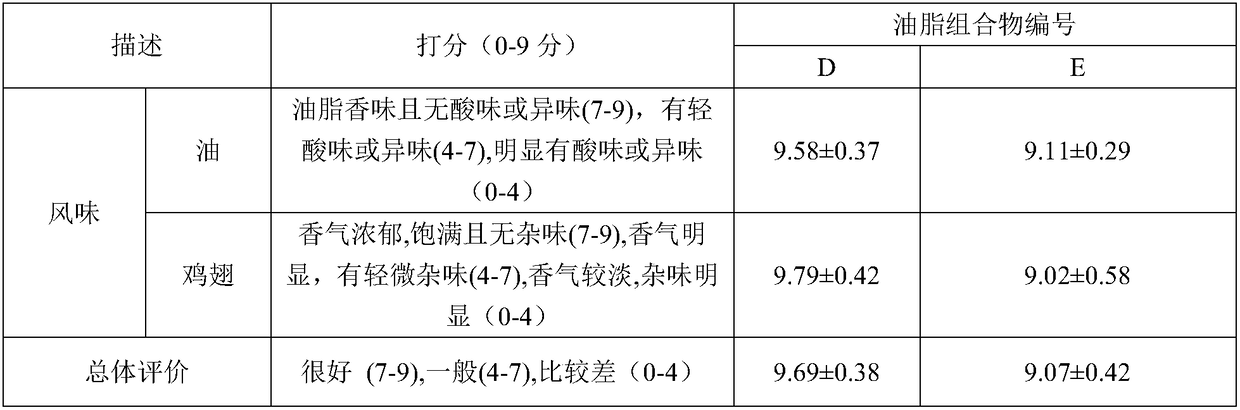

[0087] Grease composition D: Add 5500g of low-temperature deodorized refined rice oil, 4000g of sunflower oil, 500g of rapeseed oil, and 200ppm TBHQ into the batching tank, maintain the temperature at 20°C-40°C, and stir at a speed of 50r / min for 20 -30 minutes, filter and fill, control the content of unsaturated fatty acids and styrene through this deployment: C18:2+C18:3=50% by weight, (C18:2+C18:3) / styrene=1.4*10 5 .

[0088] Grease composition E: Take 5500g neutralized rice oil, 4000g sunflower oil, 500g rapeseed oil, and 200ppm TBHQ into the batching tank respectively, maintain the temperature at 20°C-40°C, and stir at a speed of 50r / min for 20- After 30 minutes, filter and fill. After testing: C18:2+C18:3=50% by weight, (C18:2+C18:3) / styrene=6.4*10 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com