Soil stabilizer and preparation method thereof

A soil stabilizer and activated carbon technology, which is applied in the field of soil stabilizer and its preparation, can solve the problems of unreasonable selection of materials, preparation process, soil structure damage, loss of nutrients, etc., so as to improve the stability performance, utilization rate and surface porosity. The effect of large and enhanced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

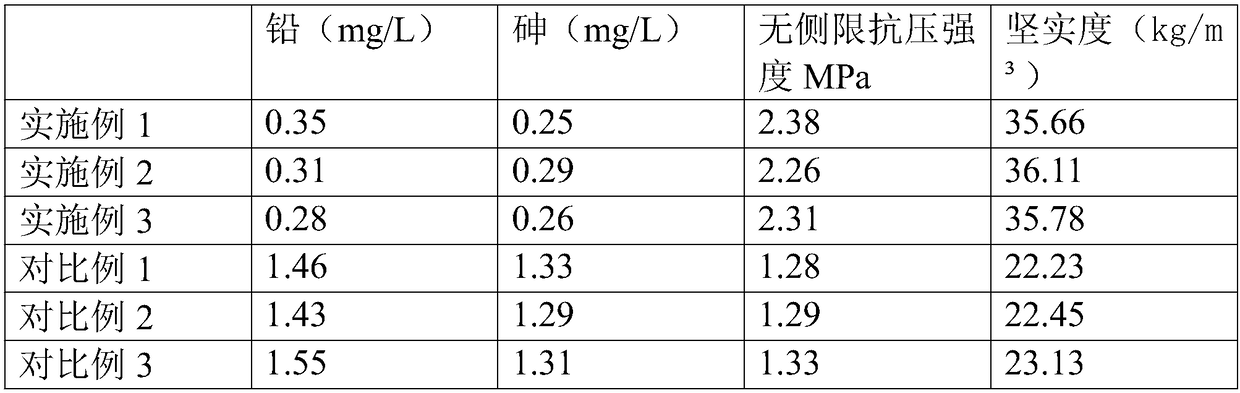

Examples

preparation example Construction

[0019] The preparation method of described modified activated carbon is as follows:

[0020] (1) Activated carbon is put into the pulverizing device and pulverized, and the pulverization time is 60min, and after pulverization is completed, pass through a 40-mesh sieve to obtain activated carbon powder;

[0021] (2) the gac obtained in step 1 is put into potassium permanganate solution for soaking treatment, and silane coupling agent is added simultaneously for stirring treatment. The stirring time is 170min. After the stirring is completed, deionized water is used for washing treatment, adjusting The pH value was 7, and the modified activated carbon was obtained after drying.

Embodiment 1

[0023] A soil stabilizer, consisting of the following raw materials in parts by weight: 5 parts of alkylbenzenesulfonic acid, 4 parts of polyoxyethylene, 6 parts of gypsum powder, 2 parts of zinc stearate, 1 part of neutral water glass, cement 2 parts, 4 parts of aluminum sulfate, 2 parts of calcium chloride, 3 parts of sodium alginate, 2 parts of polymethacrylate, 4 parts of polyisobutenyl succinimide, 2 parts of polymethyltriethoxysilane, 2 parts of fatty alcohol polyoxyethylene ethers, 4 parts of modified activated carbons, (1) take by weight the parts by weight of each material in embodiment 1, with alkylbenzenesulfonic acid, polyoxyethylene, gypsum powder, zinc stearate , neutral water glass, cement, aluminum sulfate, calcium chloride and sodium alginate are put into stirring device and carry out stirring process, stirring speed is 130r / min, and stirring time is 180min; (2) the material obtained in step 1 is added Polymethacrylate, polyisobutenyl succinimide, polymethyltr...

Embodiment 2

[0025] A soil stabilizer, consisting of the following raw materials in parts by weight: 15 parts of alkylbenzenesulfonic acid, 10 parts of polyoxyethylene, 10 parts of gypsum powder, 7 parts of zinc stearate, 6 parts of neutral water glass, cement 5 parts, 10 parts of aluminum sulfate, 8 parts of calcium chloride, 8 parts of sodium alginate, 8 parts of polymethacrylate, 9 parts of polyisobutenyl succinimide, 7 parts of polymethyltriethoxysilane, 10 parts of fatty alcohol polyoxyethylene ethers, 12 parts of modified active carbons, (1) take by weighing the parts by weight of each material in embodiment 2, with alkylbenzenesulfonic acid, polyoxyethylene, gypsum powder, zinc stearate , neutral water glass, cement, aluminum sulfate, calcium chloride and sodium alginate are put into stirring device and carry out stirring process, stirring speed is 130r / min, and stirring time is 180min; (2) the material obtained in step 1 is added Polymethacrylate, polyisobutenyl succinimide, polyme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap