Device and method for preparing nitric phosphate fertilizer from nitric acid acidolysis phosphorite freezing decalcification mother liquor

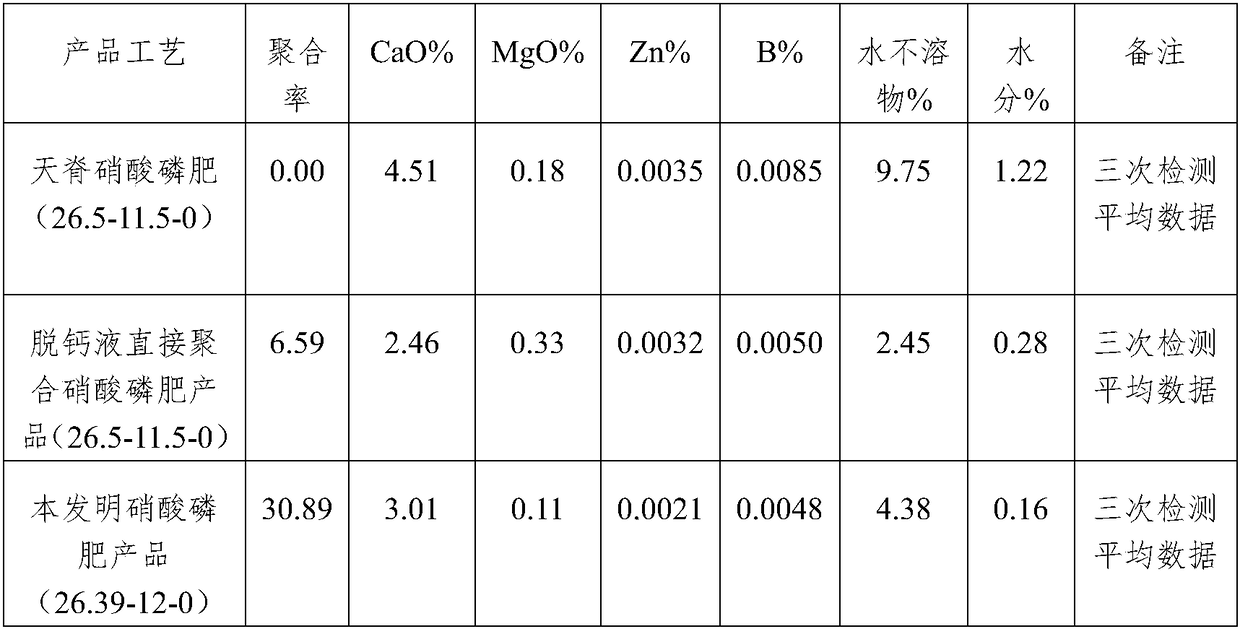

A technology of nitrophosphate fertilizer and mother liquor, which is applied in fertilization devices, ammonium nitrate fertilizer, phosphate fertilizer, etc., can solve the problems of low polymerization rate of nitrophosphate fertilizer, low quality of nitrophosphate fertilizer, and low proportion of phosphate radicals, and achieves better product performance and slow release. Enhanced effect and even distribution of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further limited below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the descriptions made.

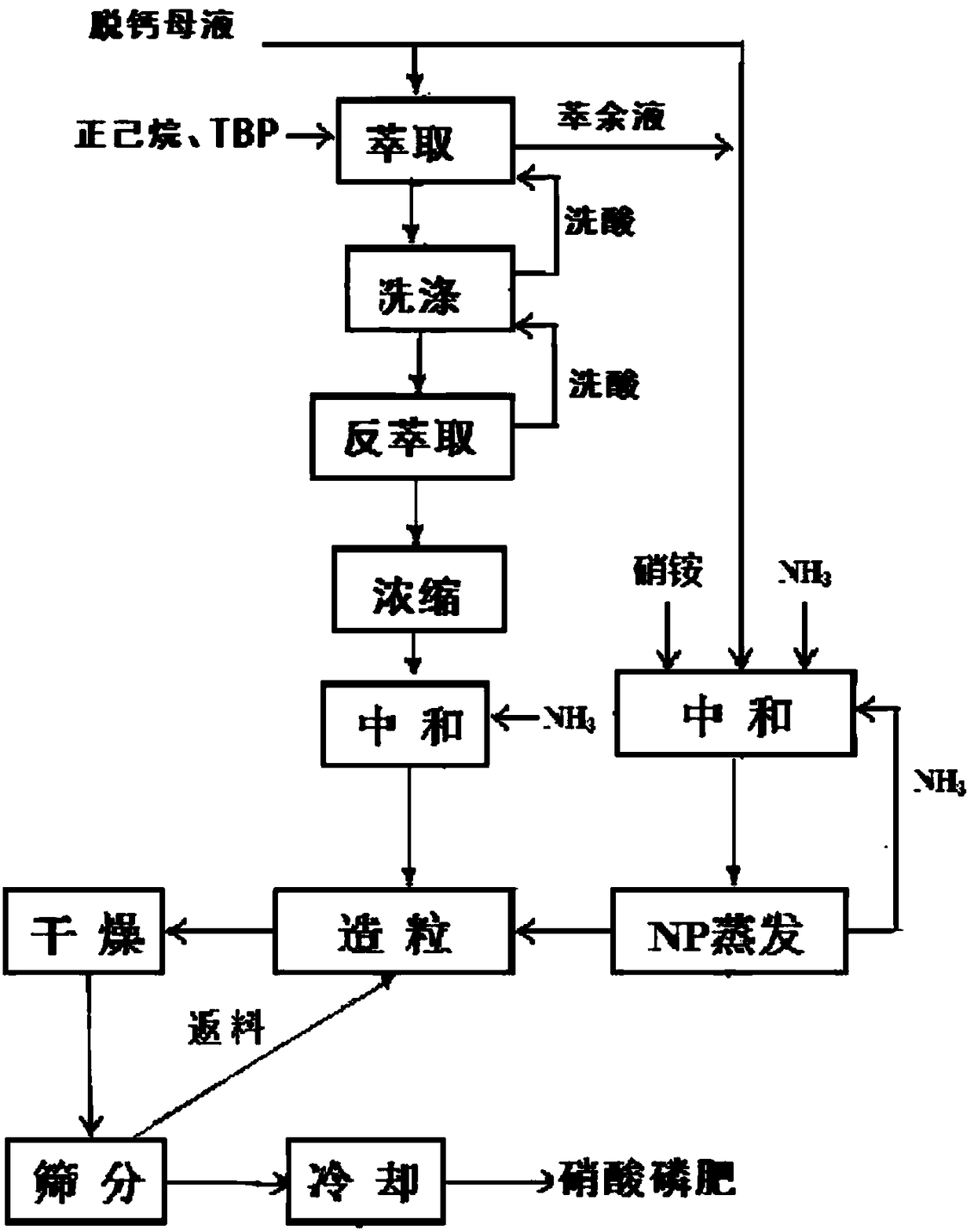

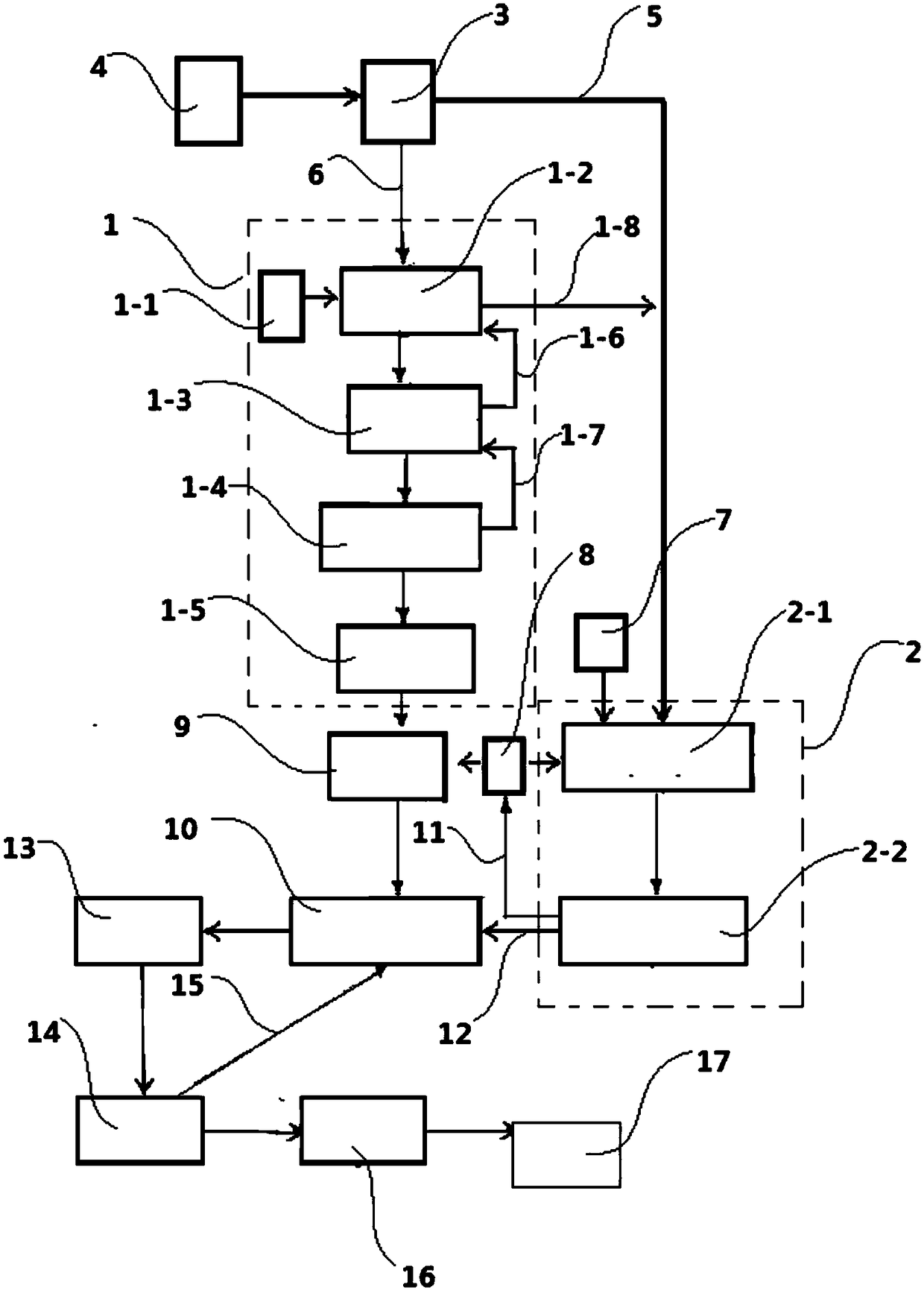

[0033] Such as figure 1 As shown, in some embodiments, the method for preparing nitrophosphate fertilizer by nitric acid acidolysis of phosphate rock freeze decalcification mother liquor, in the preparation of nitrophosphate fertilizer by freezing method, after activating phosphate rock with nitric acid, the acid solution obtained is subjected to freeze decalcification treatment Finally, the decalcified mother liquor is obtained; the decalcified mother liquor is divided into two parts, one part is extracted with an extractant, washed, back-extracted, concentrated, and neutralized to obtain polyphosphate; the other part is mixed with ammonium nitrate and ammonia After mixing, concentrate, add polyphosphate, granulate, dry, sieve and cool to obtain nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com