High-density PC polycarbonate solar panel

A polycarbonate, high-density technology, applied in the field of solar panels, can solve the problems of inability to coat protective coatings, reduce service life, and easy-to-corrosion panels, etc., and achieve a product that is easy to promote and use on a large scale, has a reasonable structure, and has a high rate of finished products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

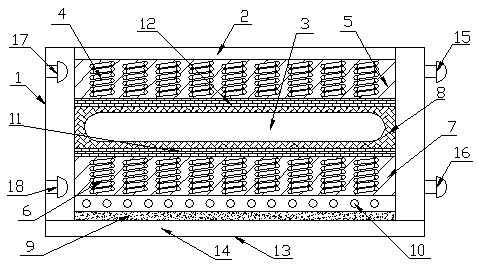

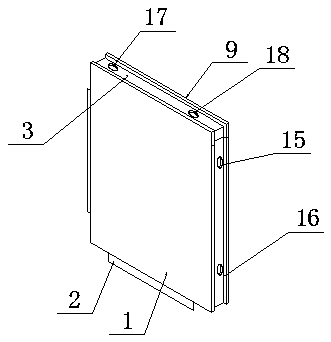

[0018] Such as Figure 1-2 As shown, the present invention provides a high-density PC polycarbonate solar panel, comprising a board body 1, an inner panel surface 2 is arranged on the inside of the board body 1, a vacuum chamber 3 is arranged inside the board body 1, and one side of the vacuum chamber 3 An inner light spring 4 is provided, and an inner polyurethane foam board 5 is arranged around the inner light spring 4, and an outer light spring 6 is arranged on one side of the vacuum chamber 3, and an outer polyurethane foam board is arranged around the outer light spring 6 7. Vacuum panels 8 are arranged around the vacuum chamber 3 , a heat insulating layer 9 is arranged inside the plate body 1 , and a mesh steel wire sheet 10 is arranged on one side of the heat insulating layer 9 .

[0019] One side of the vacuum panel 8 is provided with an outer vacuum baffle 11, one side of the vacuum panel 8 is provided with an inner vacuum baffle 12, one side of the panel body 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com