Pumped storage power station pressure piping inclined shaft non-demolition heading machine well-forming technology

A pumped-storage power station and pressure pipeline technology, applied in drilling pipes, casings, drilling equipment, etc., can solve the problems of high labor intensity and difficult working environment for workers, and achieve the convenience of conveying well washing medium, reducing the quality of bolts, improving the The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

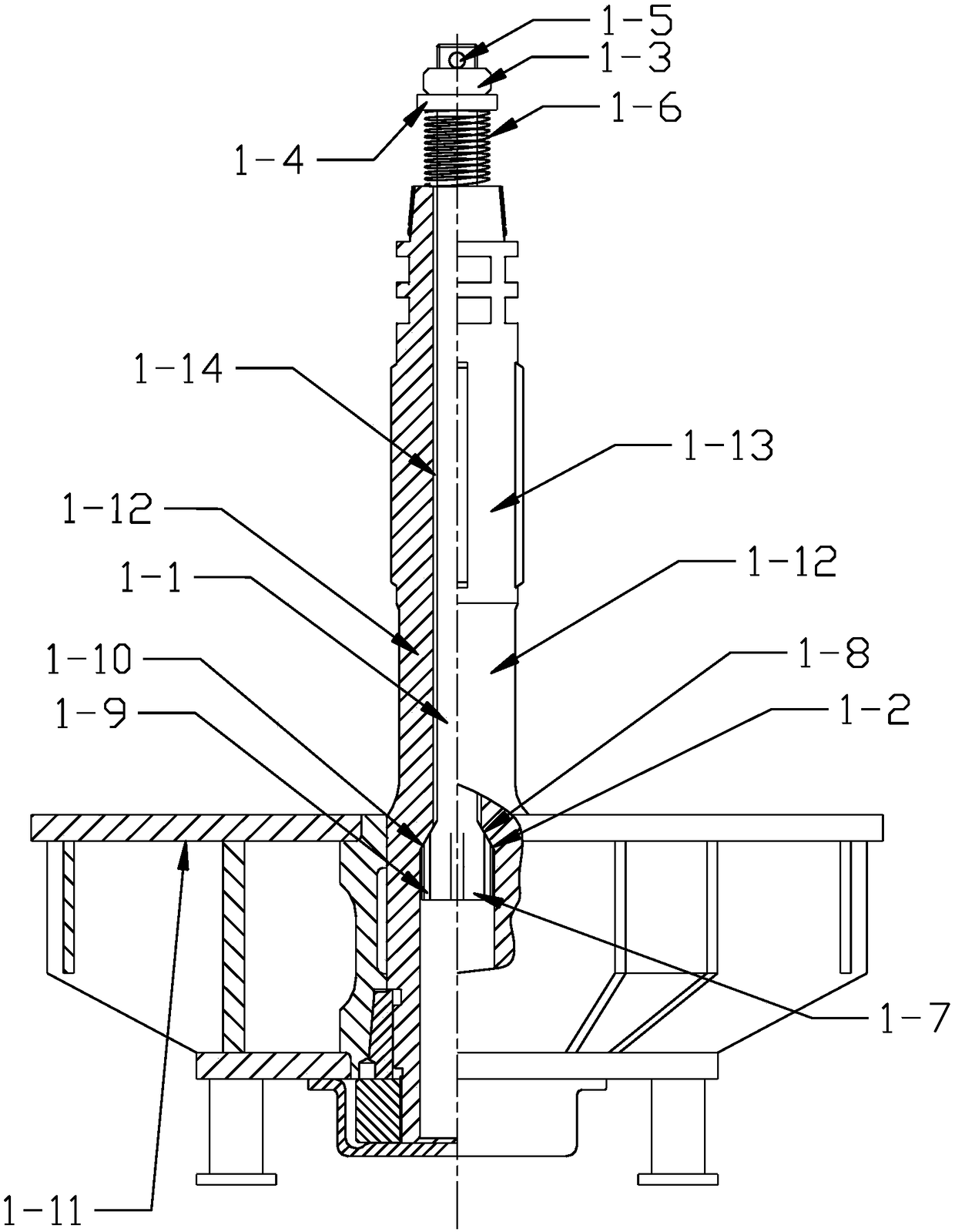

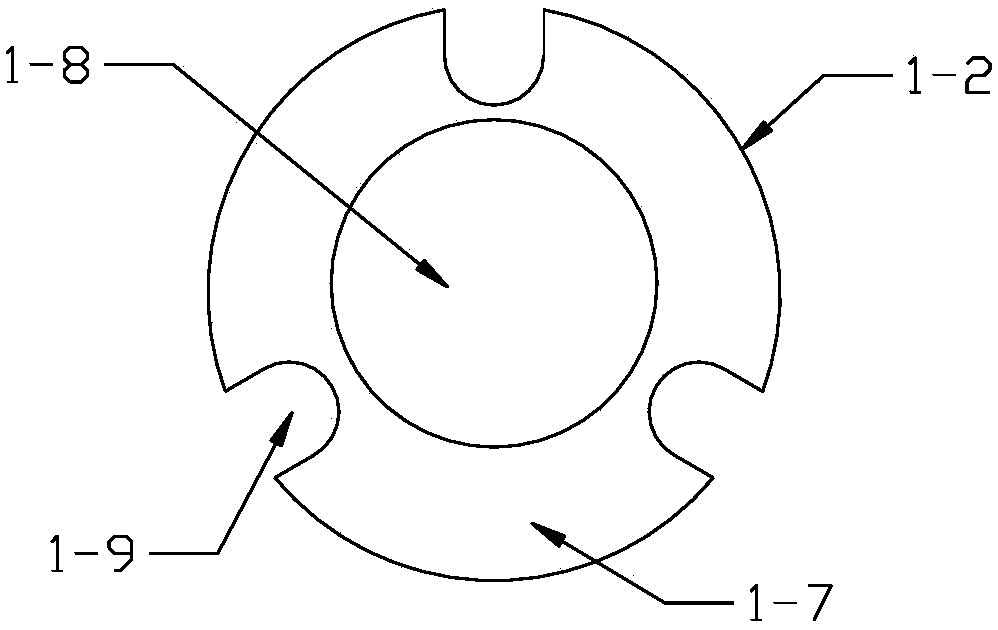

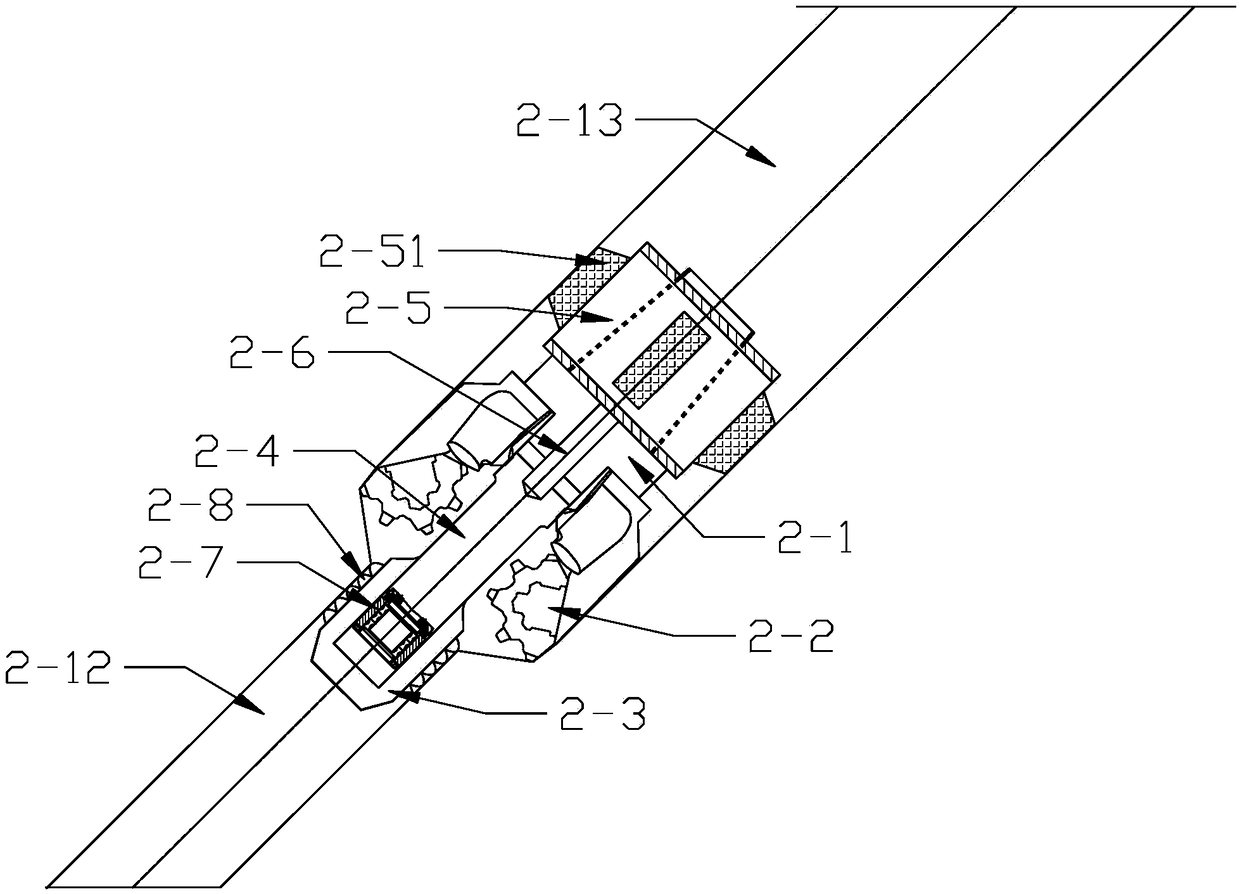

[0038] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0039] like Figure 6 to Figure 10 As shown, the non-explosive tunneling machine well forming process of the inclined well of the pressure pipeline of the pumped storage power station in this embodiment includes the following steps:

[0040] (A) In the upper horizontal section 3-1 of the pressure pipeline, based on the intersection of the axis 3-8 of the inclined shaft and the axis 3-9 of the upper horizontal tunnel, and based on the maximum weight and volume of a single piece of equipment used, design assistance Tunnel, so that the auxiliary tunnel reaches the required cross-section; install the steel structure of the lifting equipment according to the weight and volume of the excavation equipment; the construction meets the installation requirements of the directional drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com