Small-specification slender special carbon material once molding roasting burden box

A small size, carbon material technology, applied in the field of roasting furnaces, can solve the problems of molded products not being easy to stand upright, waste products out of the furnace, waste of resources, etc., to achieve the effect of ensuring air circulation efficiency, ensuring roasting effect, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

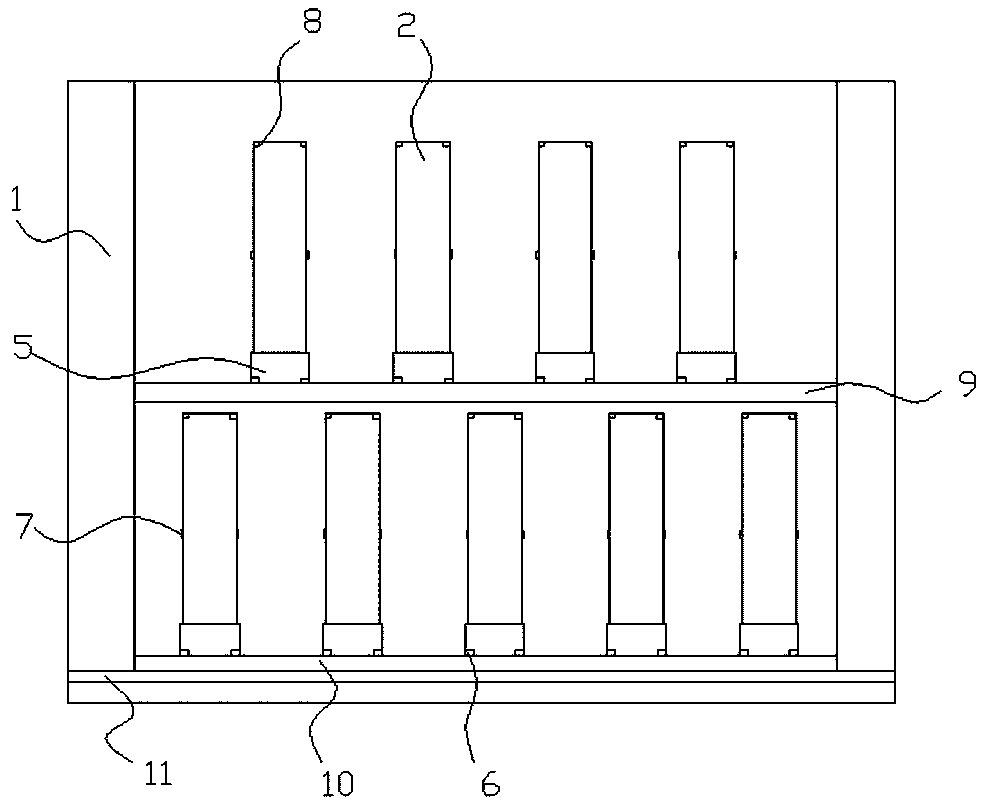

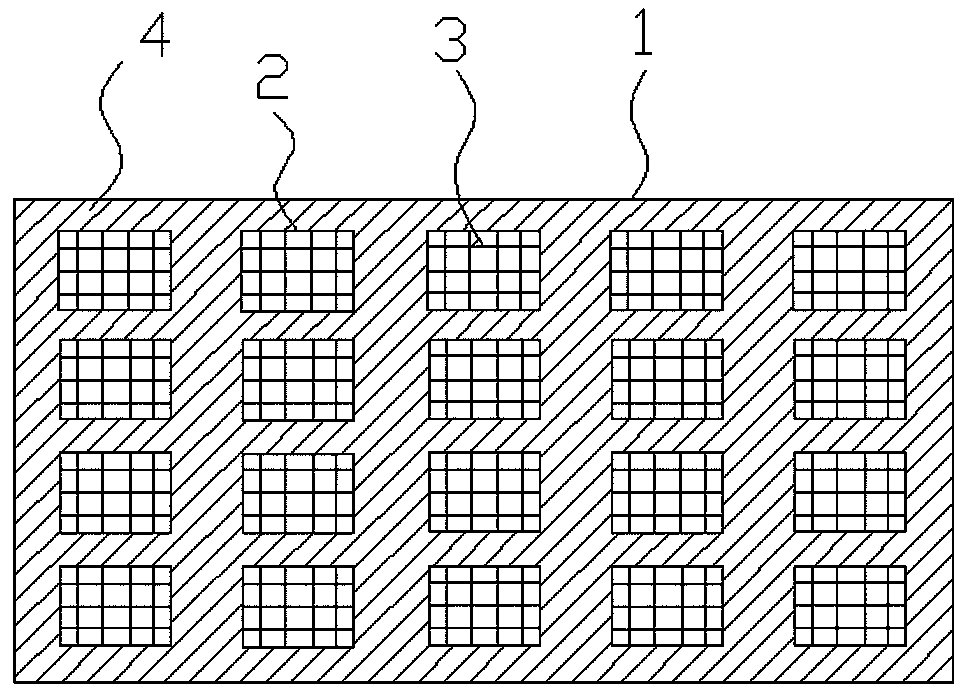

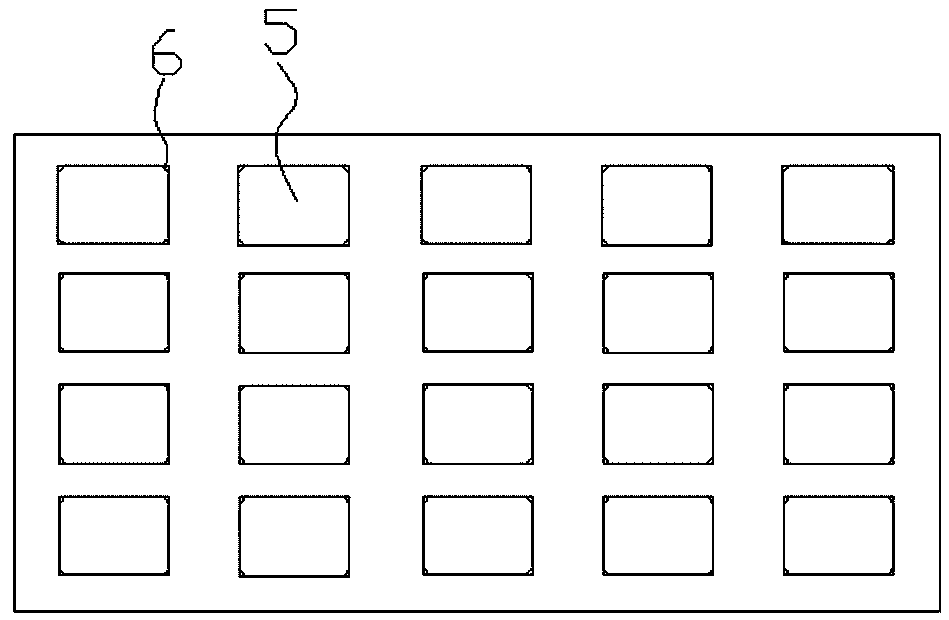

[0031] Such as Figure 1-7 As shown, a small size slender special carbon material one-time forming roasting furnace charge box includes a furnace body 1 and a fixed box 2. The furnace body 1 is made of checker bricks 15, and its four corners are made of corner checker bricks. The furnace body 1 is The rectangular structure of the upper opening 13, the middle and the bottom are provided with horizontal brackets, the middle bracket is used as the second-layer bracket 9, the bottom bracket is used as the first-layer bracket 10, and a plurality of rectangular brackets are installed above the first-layer bracket 10 and the second-layer bracket 9. The base 5 of the array, the base 5 is a rectangular dish-shaped structure, and a fixed box 2 is installed on its inner side. The fixed box 2 is a long cylindrical structure, and fillers 4 are arranged between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com