Novel industrial robot RV reducer performance test method

A technology of an industrial robot and a test method, which is applied in the performance test field of a new industrial robot RV reducer, can solve the problems of complex calculation and complicated rotary transmission error, and achieve the effects of simple calculation, simple rotary transmission error and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

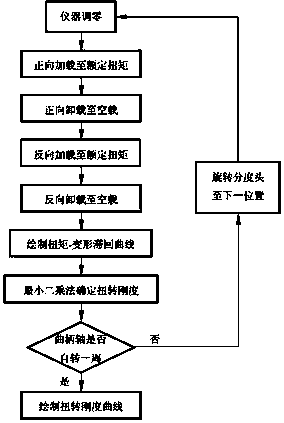

[0023] Such as figure 1 As shown, a new type of industrial robot RV reducer performance test method, the method steps include: (1) instrument zero; (2) forward loading to rated torque; (3) forward unloading to no load; (4) Reversely load to rated torque; (5) Reversely unload to no load; (6) Draw the torque deformation hysteresis curve; (7) Determine the torsional stiffness by the least square method; (8) Whether the crankshaft is self-propagating for a circle, if so, draw the torsion Stiffness curve; (9) If not, rotate the scale to the next position, set the instrument to zero, and retest.

[0024] Furthermore, during the measurement process, the following method is adopted to minimize the measurement distortion caused by the artificial influence f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com