A method for water management in alkaline anion exchange membrane fuel cells

A fuel cell water and alkaline anion technology, applied in the direction of fuel cells, fuel cell additives, solid electrolyte fuel cells, etc., can solve the problems of few improvement measures, improve output performance, prolong constant current operation time, and improve discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Select the self-made membrane electrode in the group, which uses the self-made AEH9620 membrane as the basic membrane, the ionomer is the self-made QTMA-30 resin, the catalyst is commercial Pt / C, and the catalyst loading capacity is 0.5mg Pt / cm 2 , the diffusion layer is carbon paper containing 5% PTFE with a microporous layer, and the effective area of the electrode is 5cm 2 .

[0028] The operating conditions of the battery are as follows:

[0029] The anode inlet pressure is 0.2MPa, the hydrogen flow rate is 100ml / min, and the humidification temperature is 50°C; the cathode inlet pressure is 0.2MPa, the oxygen flow rate is 200ml / min, the humidification temperature is 50°C, and the battery operating temperature is 50°C.

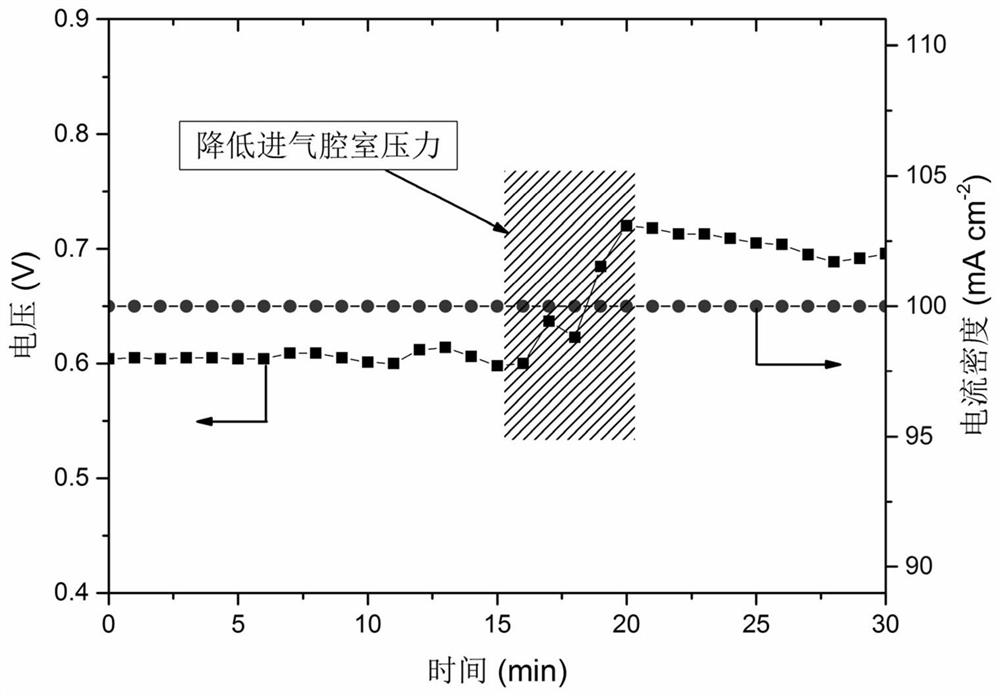

[0030] The battery load current is 100mAcm -2 , when the battery runs for 15 minutes, adjust the opening of the gas exhaust valve, reduce the pressure in the battery gas chamber from 0.2MPa to 0 (gauge pressure), and maintain it for 5 minutes. Af...

Embodiment 2

[0032] Select the self-made membrane electrode in the group, which uses the self-made AEH9620 membrane as the basic membrane, the ionomer is the self-made QTEA-58 resin, the catalyst is commercial Pt / C, and the catalyst loading capacity is 0.1mg Pt / cm 2 , the diffusion layer is carbon paper containing 5% PTFE with a microporous layer, and the effective area of the electrode is 5cm 2 .

[0033] The operating conditions of the battery are as follows:

[0034] The anode inlet pressure is 0.2MPa, the hydrogen flow rate is 100ml / min, and the humidification temperature is 50°C; the cathode inlet pressure is 0.2MPa, the oxygen flow rate is 200ml / min, the humidification temperature is 50°C, and the battery operating temperature is 50°C.

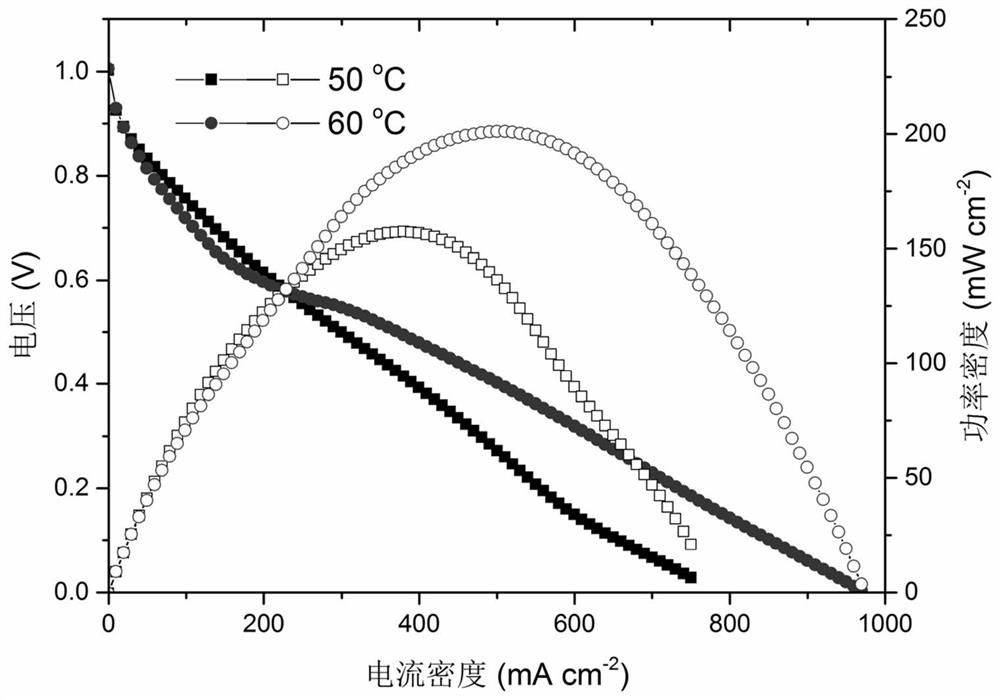

[0035] After testing the polarization curve at 50°C, raise the operating temperature of the battery to 60°C and maintain it at this temperature for 10 minutes. After the liquid water inside the battery is discharged, test the polarization curve of...

Embodiment 3

[0037] Select the self-made membrane electrode in the group, which uses the self-made AEH9620 membrane as the basic membrane, the ionomer is the self-made QTMA-30 resin, the catalyst is commercial Pt / C, and the catalyst loading capacity is 0.5mg Pt / cm 2 , the diffusion layer is carbon paper containing 5% PTFE with a microporous layer, and the effective area of the electrode is 5cm 2 .

[0038] The operating conditions of the battery are as follows:

[0039] The anode inlet pressure is 0.2MPa, the hydrogen flow rate is 100ml / min, and the humidification temperature is 50°C; the cathode inlet pressure is 0.2MPa, the oxygen flow rate is 200ml / min, the humidification temperature is 50°C, and the battery operating temperature is 50°C.

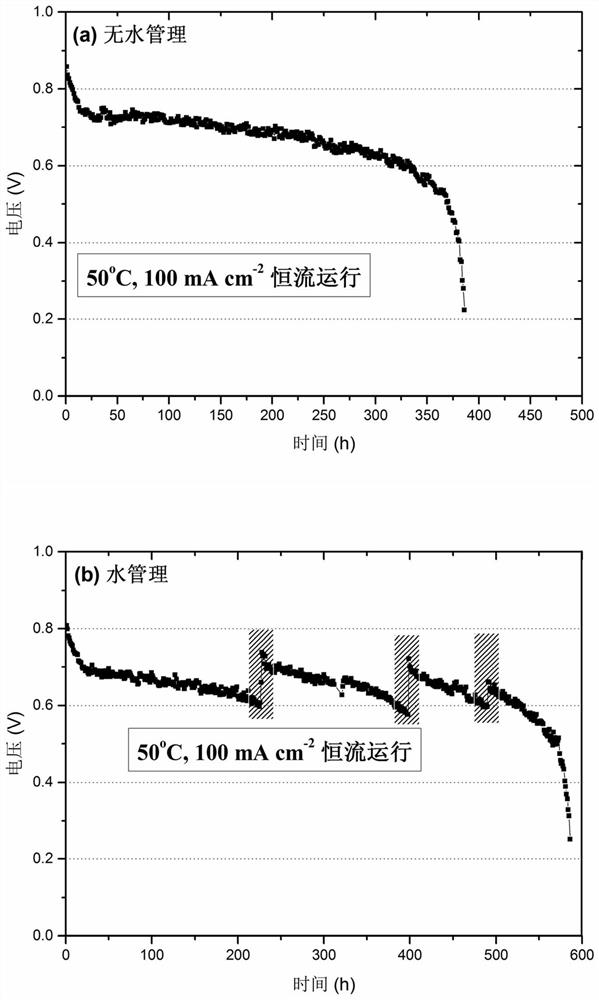

[0040] Take the decompression water management operation in Example 1 and apply it to the battery at 100mAcm -2 In the stability test under the same conditions, the running time of the battery with and without water management was compared. Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com