A three-stage generator/generator DC excitation control method with two-phase excitation structure

A DC excitation and generator technology, applied in the direction of controlling generators through magnetic field changes, can solve the problems of poor winding utilization, poor stator and rotor energy transmission, low excitation efficiency, etc., to ensure stable control, reduce volume and weight, Easy to program and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

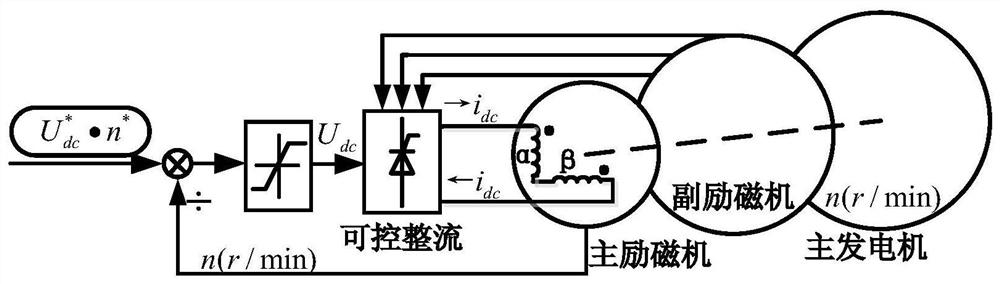

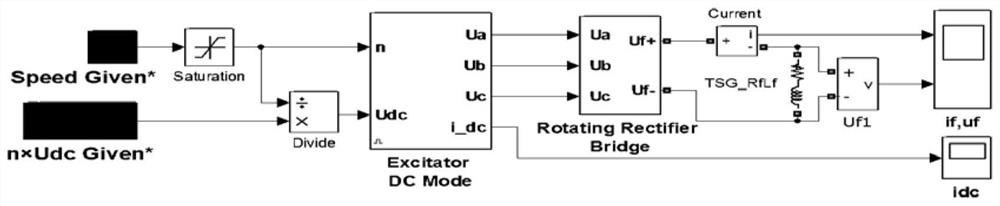

[0024] The invention proposes a three-stage starter / generator constant speed voltage product DC excitation control method with a two-phase excitation structure. The control method can ensure that the main generator excitation current remains stable during the power generation process of the three-stage starter / generator.

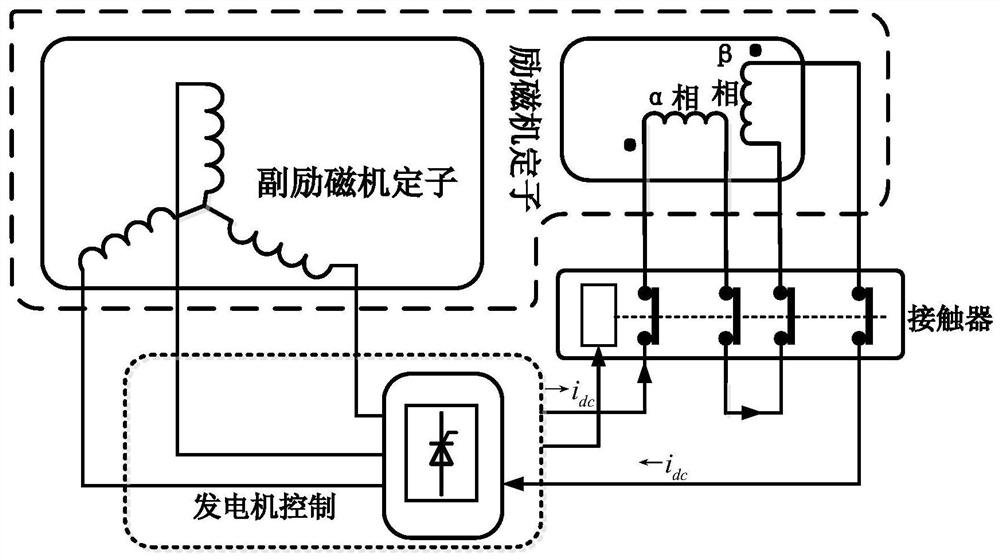

[0025] A three-stage starter / generator constant speed voltage product DC excitation control method with a two-phase excitation structure, characterized in that the stator of the three-stage starter / generator main exciter adopts two-phase symmetrical excitation windings, and after the motor starts to reach a certain speed, it passes The corresponding contactor connects the two-phase excitation windings of the main exciter in reverse series to form a one-phase winding. By adjusting and controlling the product of the DC voltage amplitude genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com