Polishing machine and polishing equipment

A polishing machine and equipment technology, applied in the direction of grinding/polishing equipment, surface polishing machine tools, metal processing equipment, etc., can solve the problems of low polishing rate between polishing abrasives and workpieces, slow drum speed, uneven polishing, etc. Achieve the effects of good fixing effect, reliable connection relationship and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

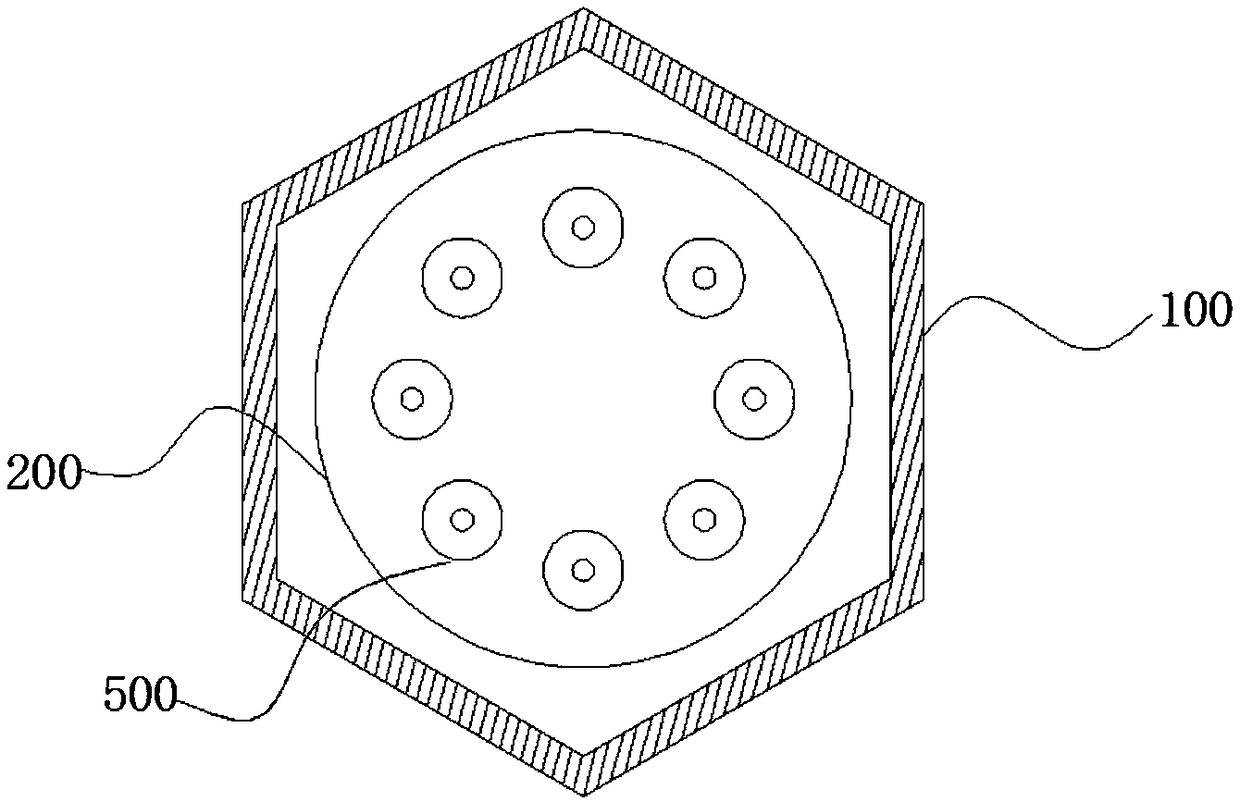

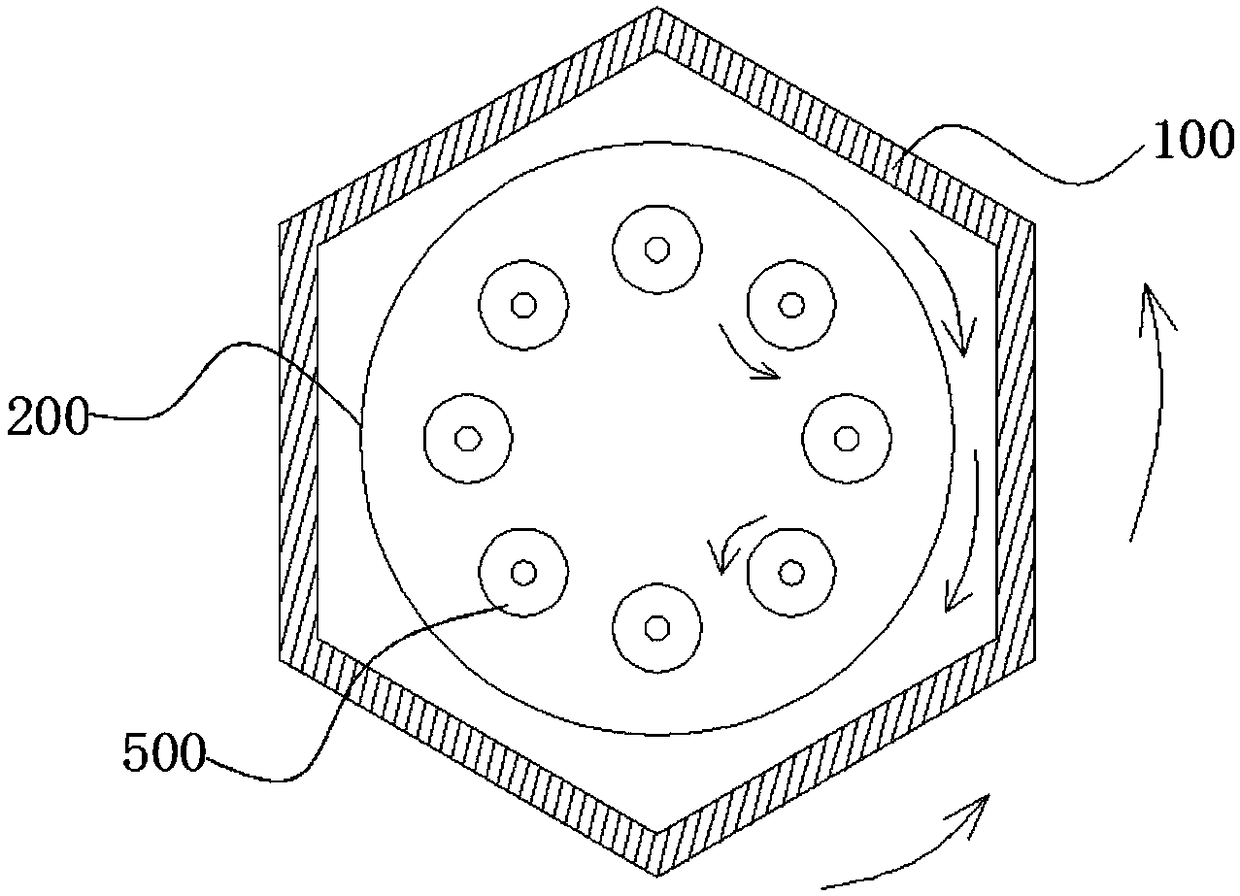

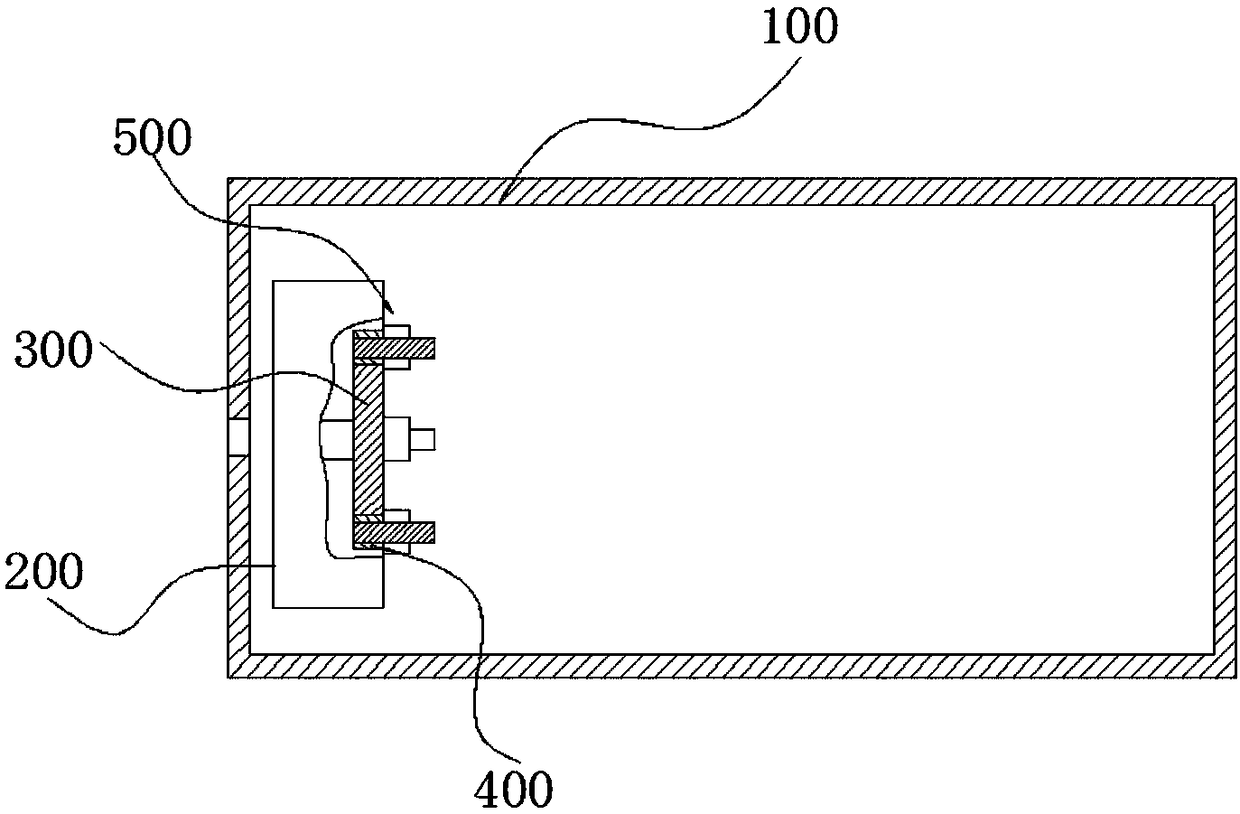

[0045] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a polishing machine, including: a cylinder 100, an abrasive (not shown in the drawings) disposed in the cylinder 100, and a tray 200, the tray 200 is used to install a workpiece to be polished; the cylinder 100 and the tray 200 The rotation direction of the workpiece to be polished is opposite, and the workpiece to be polished is pivotally connected on the tray 200, and the rotation direction of the workpiece to be polished is the same as or opposite to that of the tray 200 (the rotation direction of the workpiece to be polished is opposite to that of the tray 200, see figure 2 shown); the cylinder 100 is connected with a first driving device for driving its rotation, and the workpiece to be polished and the pallet 200 are connected with a second driving device for driving both rotations; the cylinder 100, the workpiece to be polished and the pallet 200 are all around their own axis turn.

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com