Automatic tensioning control device and control method

A control device and automatic technology, which is applied in the direction of transportation and packaging, ship parts, tugboats, etc., can solve the problems of disconnected cables, threats to the safety of three-purpose workboats and offshore platforms, and the length of cables cannot be adjusted, so as to avoid threats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

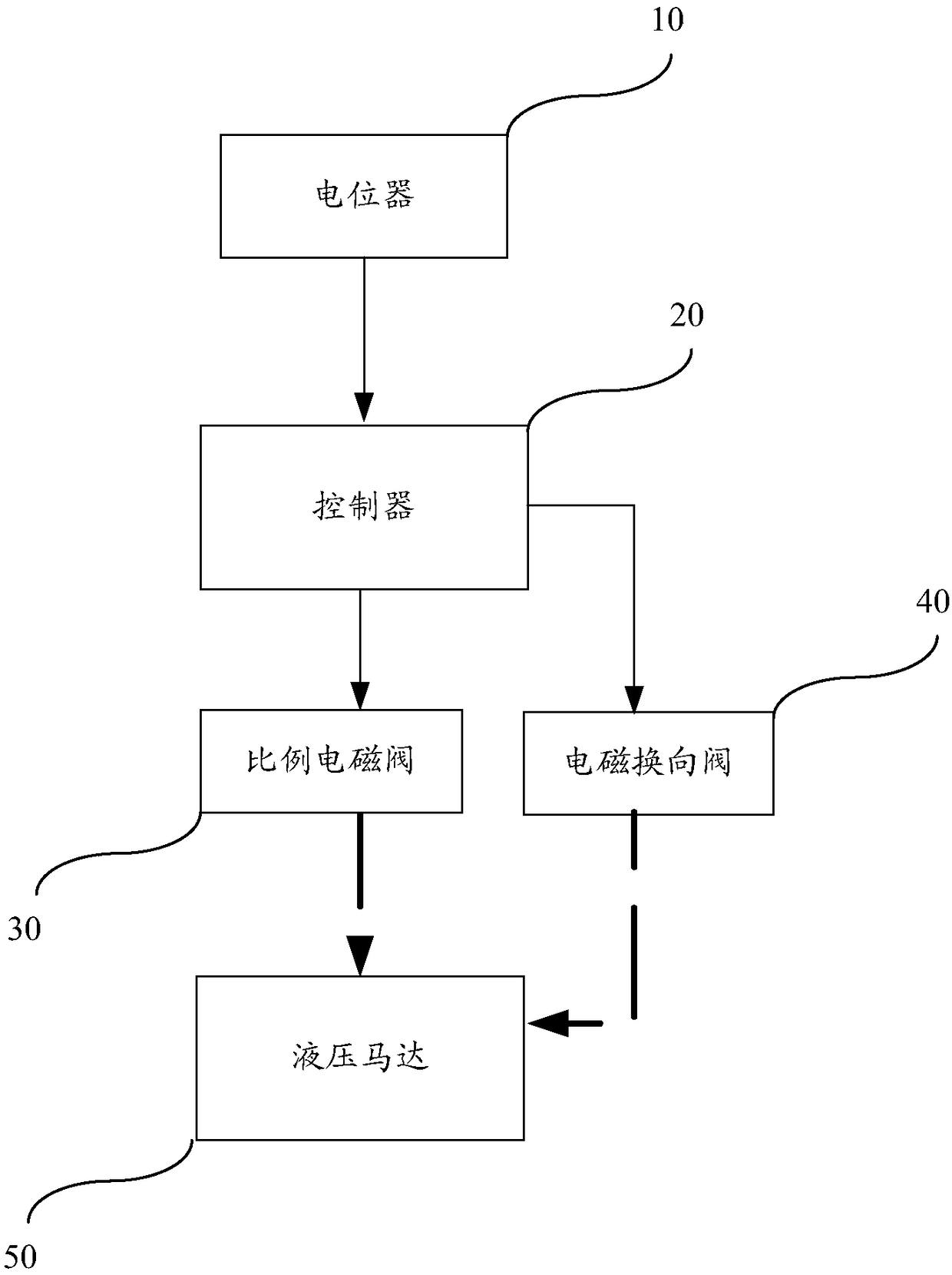

[0071] An embodiment of the present invention provides an automatic tension control device, which is suitable for a cable winch driven by a hydraulic motor. The drag winch includes a drum connected to the hydraulic motor and a cable wound on the drum. see figure 1 , the automatic tensioning device includes a potentiometer 10, a controller 20, a proportional electromagnetic valve 30 and an electromagnetic reversing valve 40, the controller 20 is electrically connected to the potentiometer 10, the proportional electromagnetic valve 30 and the electromagnetic reversing valve 40 respectively, and the proportional electromagnetic The valve 30 is arranged on the hydraulic oil circuit communicated with the oil inlet port of the hydraulic motor 50 , and the electromagnetic reversing valve 40 is arranged on the hydraulic oil circuit communicated with the control oil port of the hydraulic motor 50 .

[0072] In a specific implementation, the hydraulic oil circuit connected to the oil in...

Embodiment 2

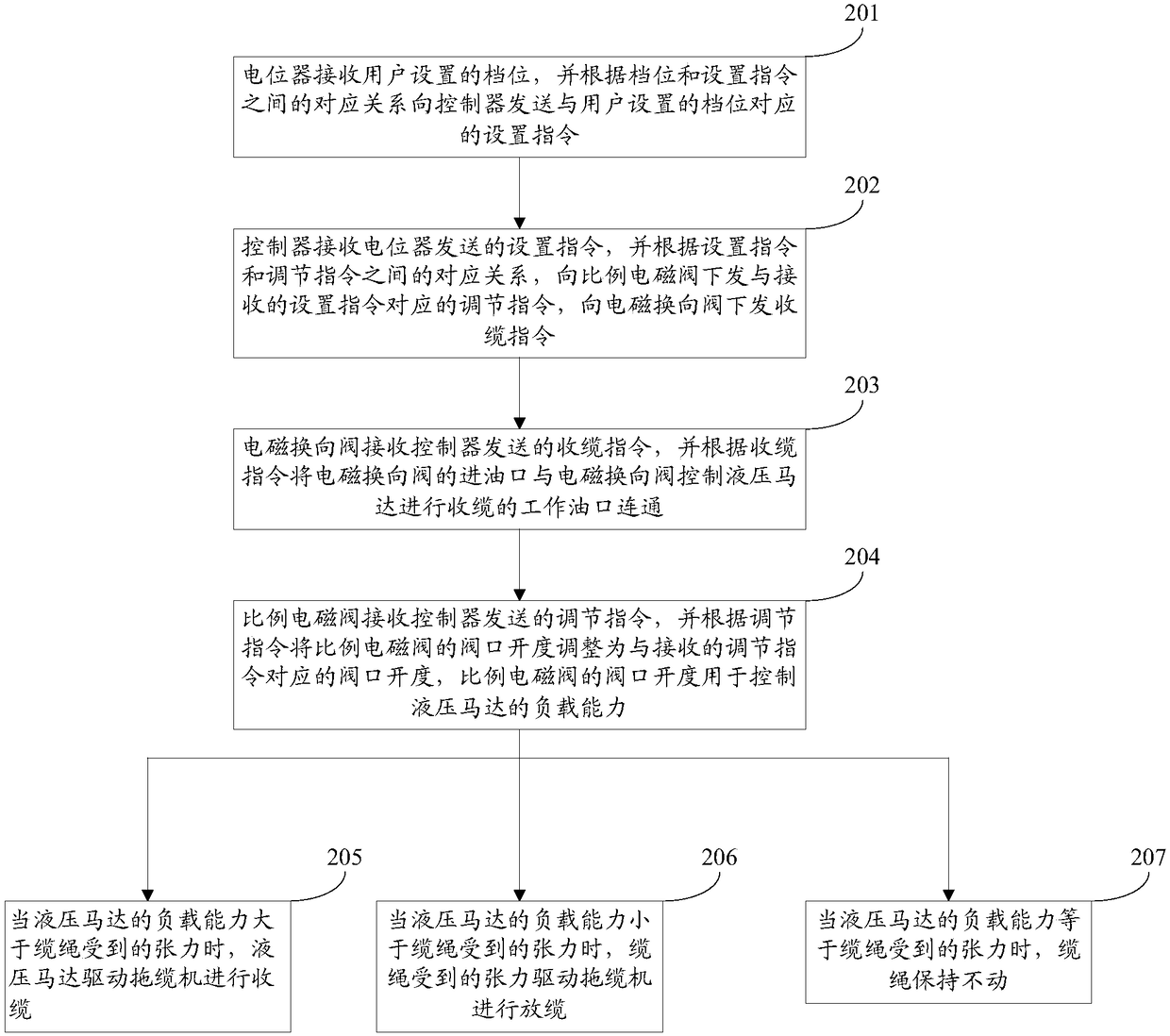

[0158] An embodiment of the present invention provides an automatic tension control method, which is suitable for a cable winch driven by a hydraulic motor, and the winch winch includes a drum connected to the hydraulic motor and a cable wound on the drum. The automatic tension control method is realized by the automatic tension control device provided in Embodiment 1, see figure 2 , the automatic tension control method includes:

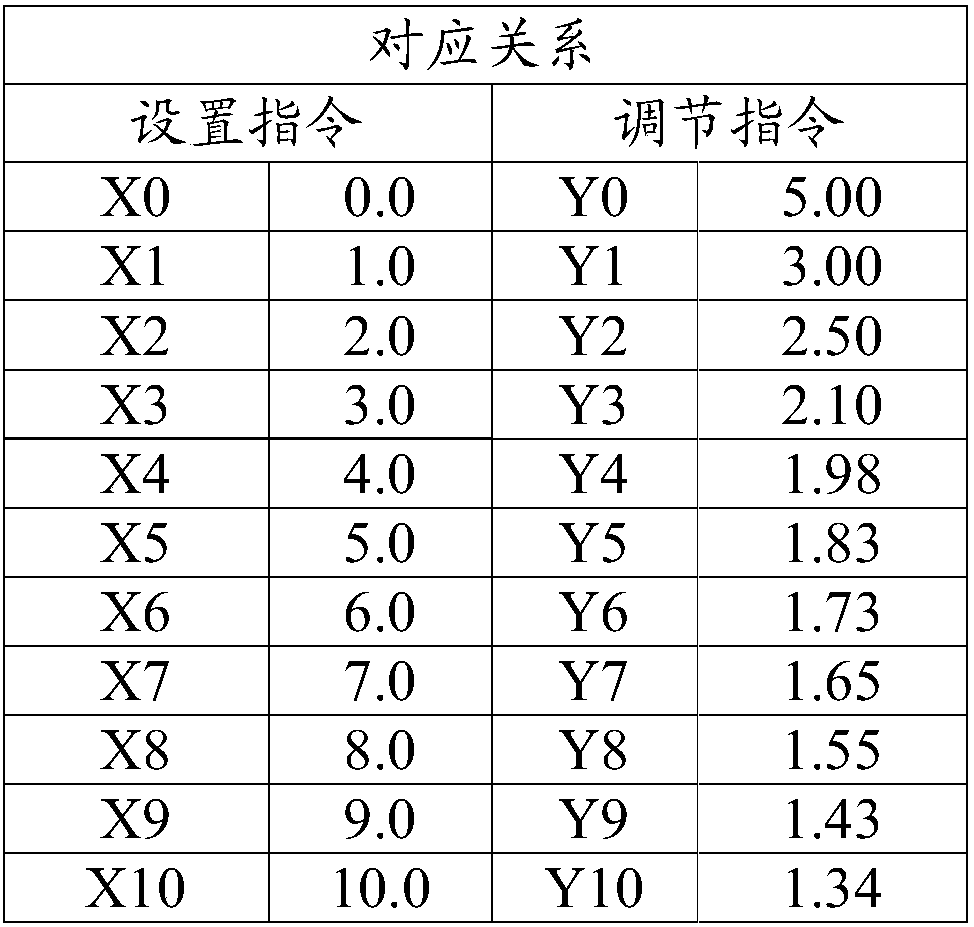

[0159] Step 201: The potentiometer receives the gear position set by the user, and sends a setting command corresponding to the gear position set by the user to the controller according to the correspondence between the gear position and the setting command.

[0160] Step 202: The controller receives the setting instruction sent by the potentiometer, and according to the corresponding relationship between the setting instruction and the adjustment instruction, sends the adjustment instruction corresponding to the received setting instruction to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com