Chabazite molecular sieve and application thereof

A technology of molecular sieve and chabazite, which is applied in the field of chabazite molecular sieve and its application, can solve the problems of low crystallinity of chabazite and difficulty in meeting practical application requirements, and achieve low production cost, good thermal stability and hydrothermal stability of products , The effect of improving the separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

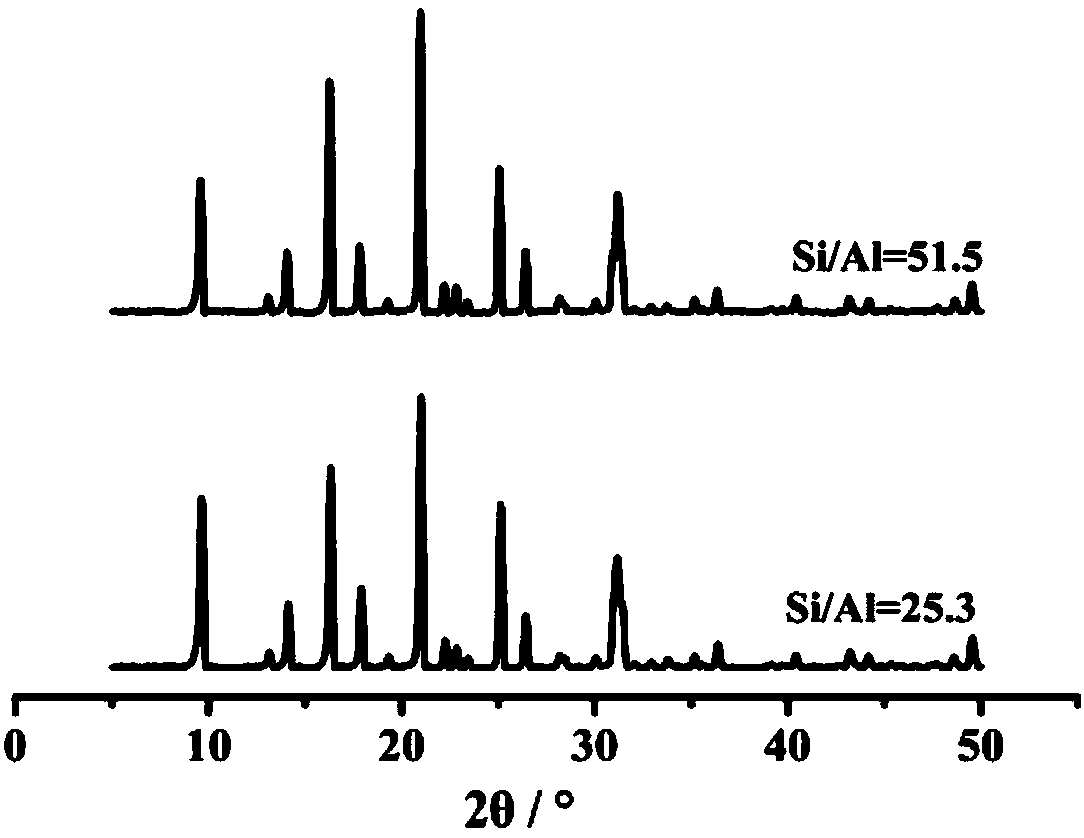

Embodiment 1

[0031] (1) Mix 0.4167g NaOH and 0.164g NaAlO 2 Dissolve in 26.2 g of deionized water, and add 10.55 g of N,N,N-trimethyl-1-adamantyl ammonium hydroxide under stirring. Stirring was continued until the solid was completely dissolved and cooled to room temperature, 10.1 g of 30% silica sol was slowly added dropwise under vigorous stirring and stirring was continued for 6 hours. The mixed solution was transferred to a high-pressure reactor equipped with a polytetrafluoroethylene liner for dynamic crystallization at 160°C for 4 days. After the reaction was completed, the temperature was naturally lowered to room temperature, and the solid product was filtered out by vacuum suction, and washed with a large amount of deionized water until the pH of the filtrate was less than 8. The product was dried at 100° C. for 12 hours to obtain a white powder, and then calcined at 550° C. for 12 hours to remove the template agent, and the calcining atmosphere was air.

[0032] (2) Weigh 1g of...

Embodiment 2

[0035] (1) Mix 0.4167g NaOH and 0.156g Al(OH) 3 It was dissolved in 21.36 g of deionized water, and 10.55 g of N,N,N-trimethyl-1-adamantyl ammonium hydroxide was added under stirring. Stirring was continued until the solid was completely dissolved and cooled to room temperature, 10.1 g of 30% silica sol was slowly added dropwise under vigorous stirring and stirring was continued for 6 hours. The mixed solution was transferred to a high-pressure reactor equipped with a polytetrafluoroethylene liner for dynamic crystallization at 160°C for 4 days. After the reaction was completed, the temperature was naturally lowered to room temperature, and the solid product was filtered out by vacuum suction, and washed with a large amount of deionized water until the pH of the filtrate was less than 8. The product was dried at 100° C. for 12 hours to obtain a white powder, and then calcined at 550° C. for 12 hours to remove the template agent, and the calcining atmosphere was air.

[0036]...

Embodiment 3

[0039] (1) Mix 0.4167g NaOH and 0.078g Al(OH) 3 It was dissolved in 21.22 g of deionized water, and 10.55 g of N,N,N-trimethyl-1-adamantyl ammonium hydroxide was added under stirring. Stirring was continued until the solid was completely dissolved and cooled to room temperature, 10.3 g of 30% silica sol was slowly added dropwise under vigorous stirring and stirring was continued for 6 hours. The mixed solution was transferred to a high-pressure reactor equipped with a polytetrafluoroethylene liner for dynamic crystallization at 160°C for 4 days. After the reaction was completed, the temperature was naturally lowered to room temperature, and the solid product was filtered out by vacuum suction, and washed with a large amount of deionized water until the pH of the filtrate was less than 8. The product was dried at 100° C. for 12 hours to obtain a white powder, and then calcined at 550° C. for 12 hours to remove the template agent, and the calcining atmosphere was air.

[0040]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap