Purification device for ultrapure rare earth metals and method for purifying rare earth by utilizing same

A purification device and rare earth metal technology, applied in the field of new energy materials, can solve the problems of inability to accurately control the temperature of rare earth oxides in kilns, inability to mass industrial production, and unstable product performance, saving labor time, saving energy, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

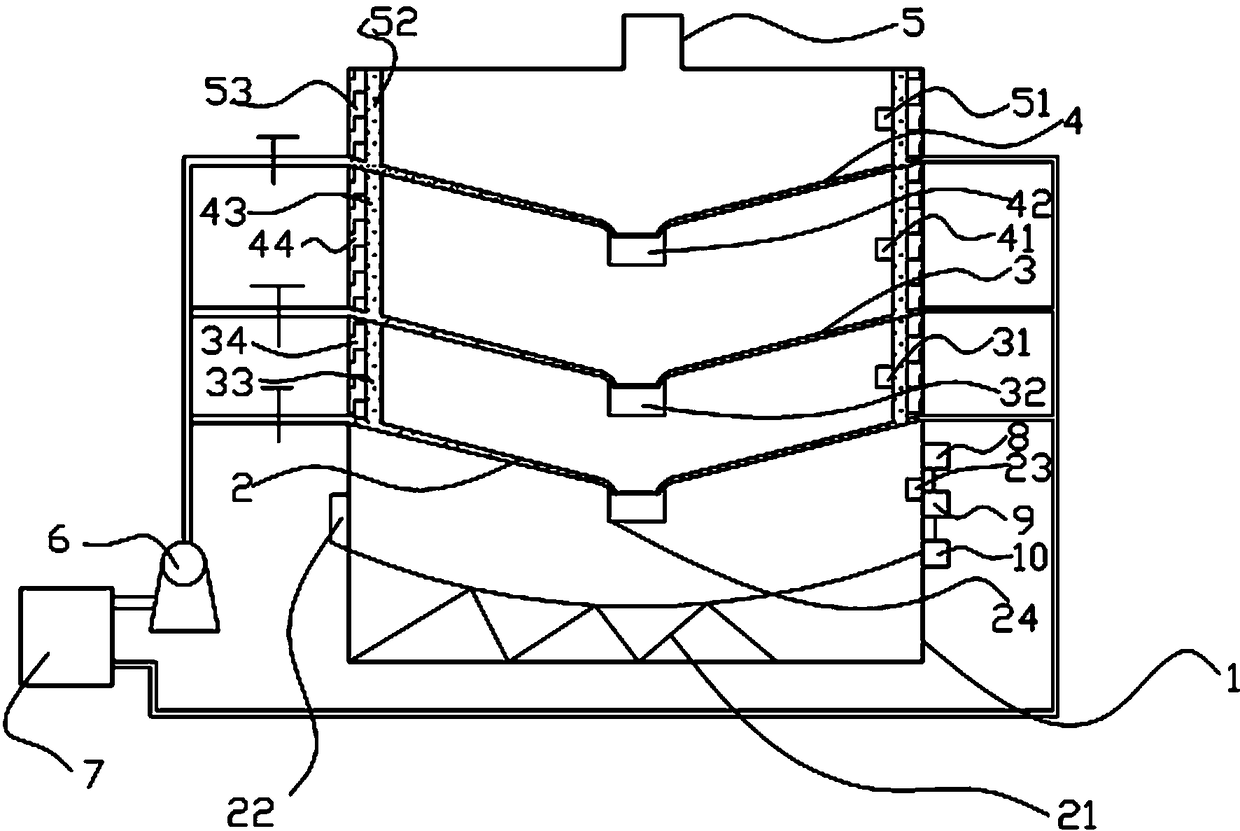

[0043] Example 1 A purification device for ultra-pure rare earth metals

[0044] This embodiment is a purification device for ultra-pure rare earth metals, such as figure 1As shown, it includes a furnace body 1, the top of the furnace body 1 is provided with a gas outlet 5, and the bottom of the furnace body 1 is provided with a feed port 22 for sending the rare earth oxide material to be purified into the furnace body 1, and the furnace body 1 A heating device 21, a cooling plate, and a temperature control device are also provided.

[0045] (1) Heating device 21

[0046] The heating device 21 is arranged at the bottom of the furnace body 1, and is used to heat the rare earth oxides that need to be purified, that is, the rare earth oxides that need to be purified are placed on the heating pot at the bottom, and the heating device 21 is located under the heating pot, and the heating device 21 is controlled by electric control. Heating temperature and time.

[0047] (2) Cooli...

Embodiment 2

[0059] Example 2 A purification device for ultra-pure rare earth metals

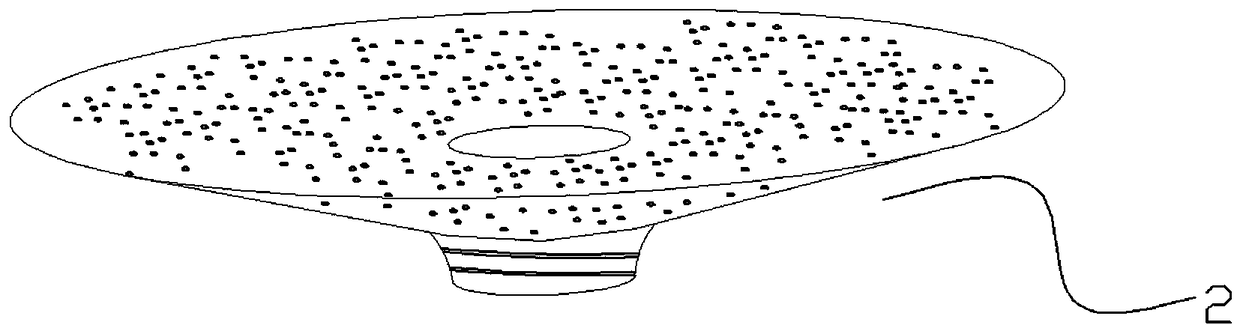

[0060] This embodiment is similar to Embodiment 1, and the difference is only that the first graphite plate 2, the second graphite plate 3 and the third graphite plate 4, the first collection box 24, the second collection box 32, and the third collection box 42 different structures, in this embodiment, the first graphite plate 2, the second graphite plate 3 and the third graphite plate 4 have the same structure, the first collection box 24, the second collection box 32 and the third collection box 42 have the same structure .

[0061] Taking the structure of the first graphite plate 2 as an example, the first graphite plate 2 is a trumpet-shaped structure, and the middle part is provided with a strip-shaped through groove extending along its diameter direction, the through groove extends downward, and the lower outer wall of the through groove is provided with The chute extending along the length direct...

Embodiment 3

[0063] Example 3 A purification method for ultrapure rare earth metals

[0064] Utilize the purification device of a kind of ultra-pure rare earth metal of above-mentioned embodiment 1 or 2 to carry out, and purification method is carried out successively according to the following step order:

[0065] (31) Smash

[0066] Take rare earth oxide Pr 6 o 11 、Nd 2 o 3 and Sm 2 o 3 , pulverize it to 100-200 meshes, mix it evenly with the reducing metal simple substance La, the weight ratio of the rare earth oxide to the reducing metal simple substance is 1:1, and briquette under 12MPa to obtain A1;

[0067] (32) heating

[0068] Put A1 into the ultra-pure rare earth metal purification device, pump it to a vacuum of 3Pa, heat it at 1200°C, and keep it for 25h to get B1;

[0069] (33) cooling down

[0070]Lower the temperature of B at a temperature 10-50°C lower than the melting point of the purified rare earth metal, that is, according to the height of the melting point, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com