LED lamp with concurrent flow vapor chamber radiator

A technology of LED lamps and vapor chambers, which is applied to refractors, lighting and heating equipment, and components of lighting devices. The effect of light source life and enhanced heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

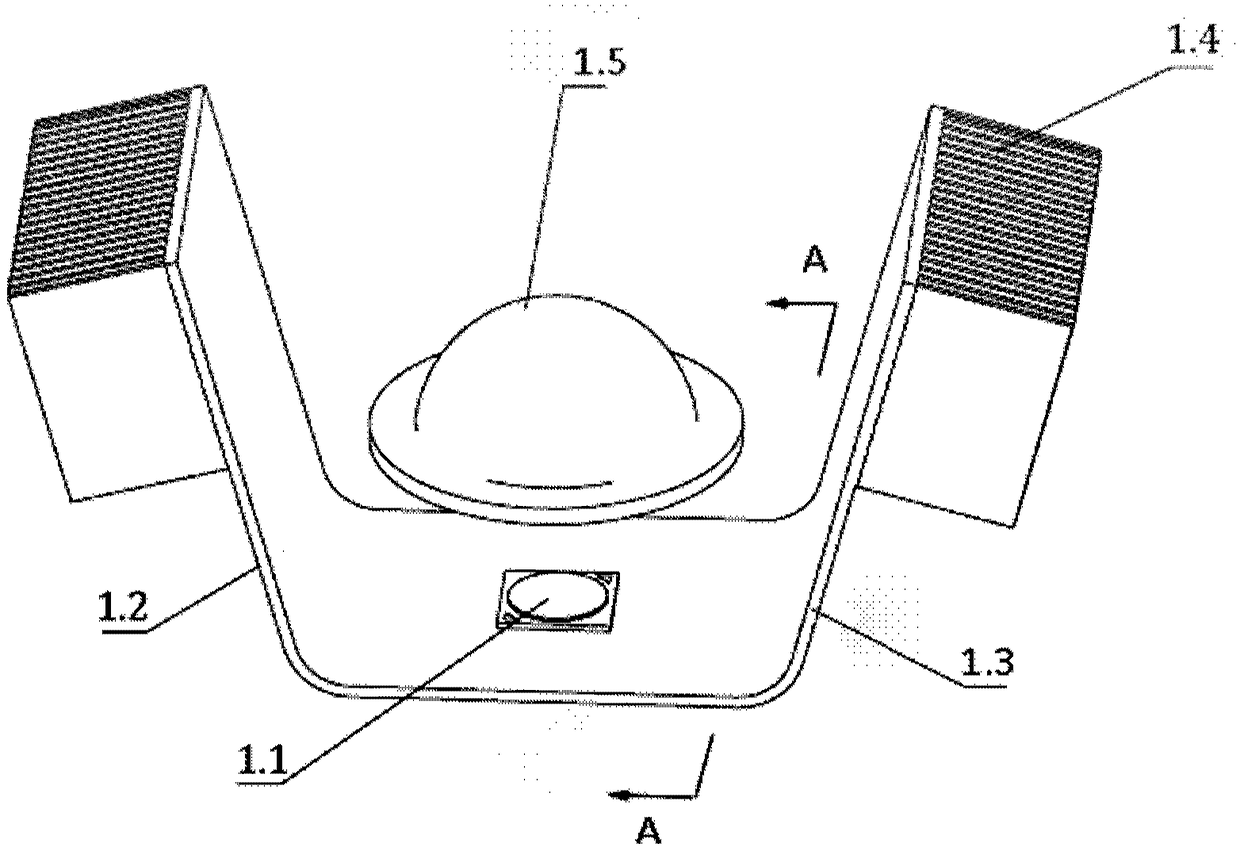

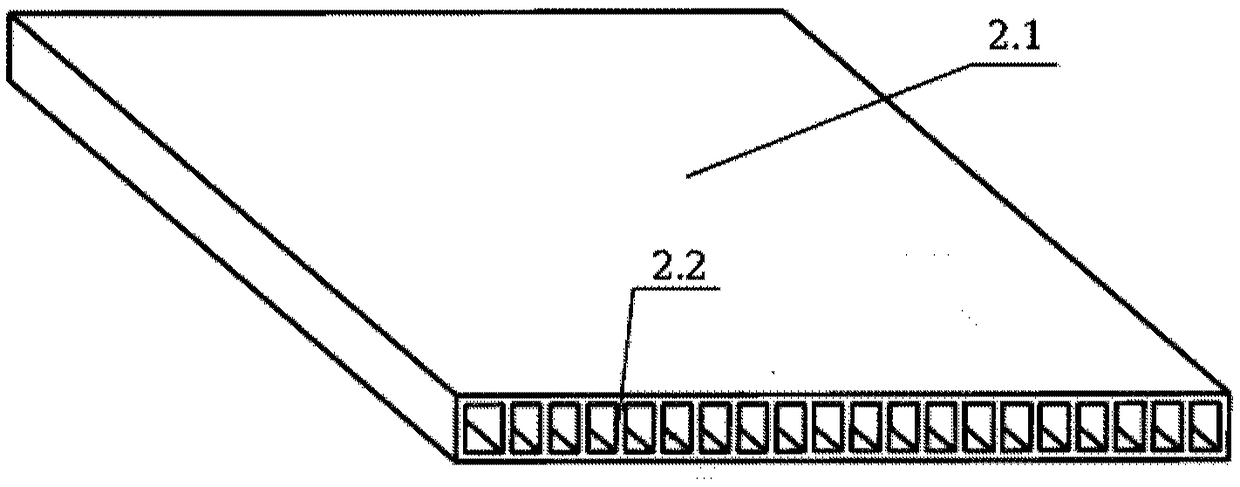

[0019] The invention provides an LED lamp with a parallel flow uniform temperature plate radiator, which includes an LED light source and a parallel flow uniform temperature plate radiator. The parallel flow vapor chamber radiator includes a parallel flow vapor chamber, and the parallel flow vapor chamber includes a flat tube and at least one heat conducting sheet; the flat tube is a flat sealed tube with upper and lower planes and a gap in the middle; the heat conducting sheet Arranged inside the flat tube, connecting the upper and lower tube walls of the flat tube and running through both ends of the flat tube; the heat conducting sheet divides the inside of the flat tube into multiple cavities; the cavity is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com