Universal mechanism

A technology of universal mechanism and universal head, which is applied in the direction of measuring devices, instruments, surveying and navigation, etc., can solve the problems of low response characteristics, low reliability, and many intermediate transmission links, so as to reduce the size and weight and improve control The effect of precision and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

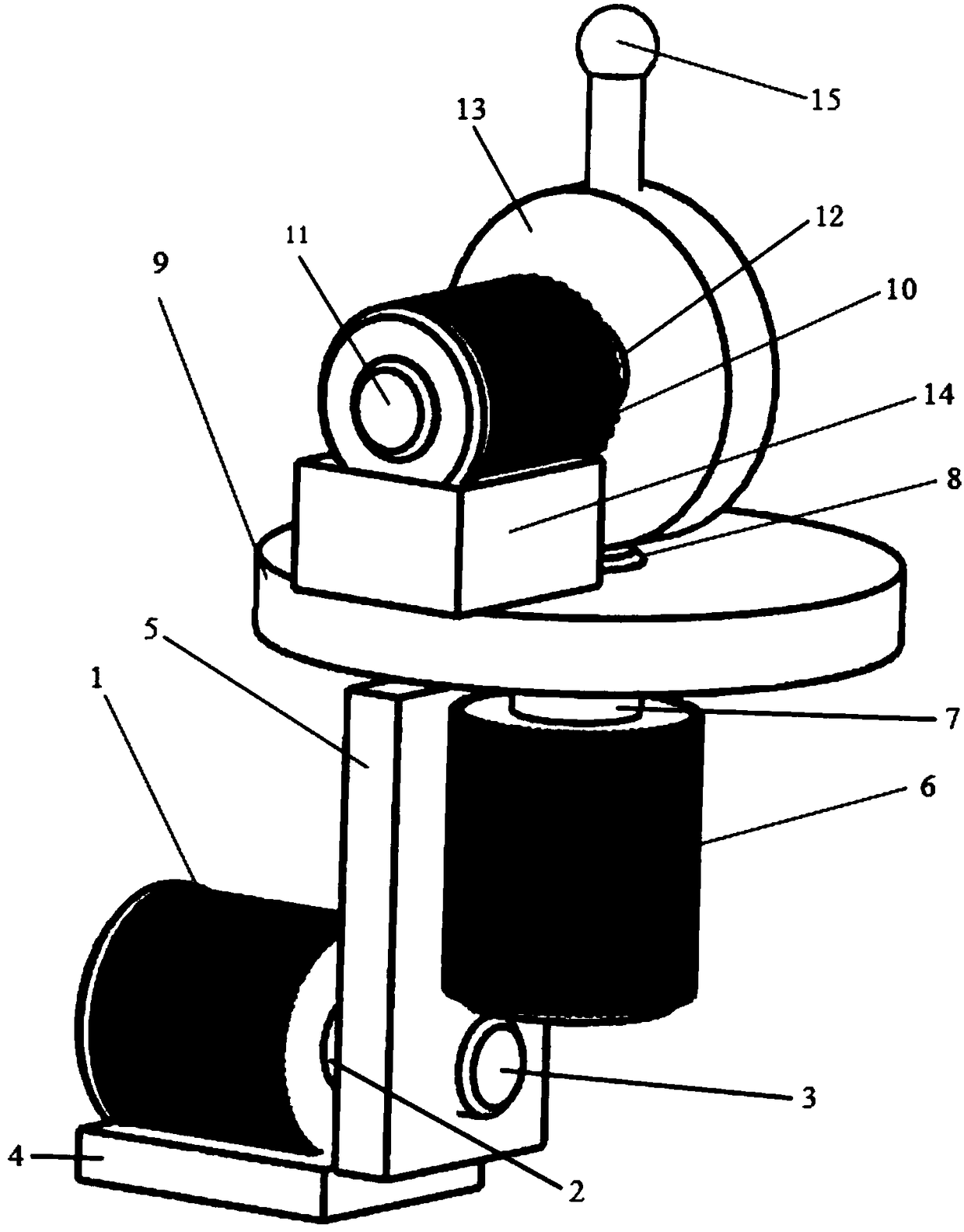

[0020] Such as figure 1 The shown universal mechanism is mainly composed of X-direction rotation mechanism, Y-direction rotation mechanism, Z-direction rotation mechanism, universal head and control system. Among them, the X-direction rotating mechanism is mainly composed of the first rotating motor 1, the first clutch 2, the electromagnetic clamp, the first shaft 3, the first mounting plate 4 and the rotating plate 5, and the Y-direction rotating mechanism is mainly composed of the second rotating motor 6 , a second clutch 7, an electromagnetic clamp, a second shaft 8 and a first circular rotating disk 9, and the Z-direction rotating mechanism is mainly composed of a third rotating motor 10, a third clutch 11, an electromagnetic clamp, and a third shaft 12. The second circular rotating disk 13 and the second mounting plate 14 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com